Landscaping tea plate and manufacturing process thereof

A technology of making crafts and tea trays, which is applied to trays, household containers, etc., can solve problems such as low production efficiency, waste of resources, monotonous colors, etc., and achieve the effect of reducing production costs, reducing waste, and increasing aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The manufacturing process of the landscaping tea tray includes the following steps in turn:

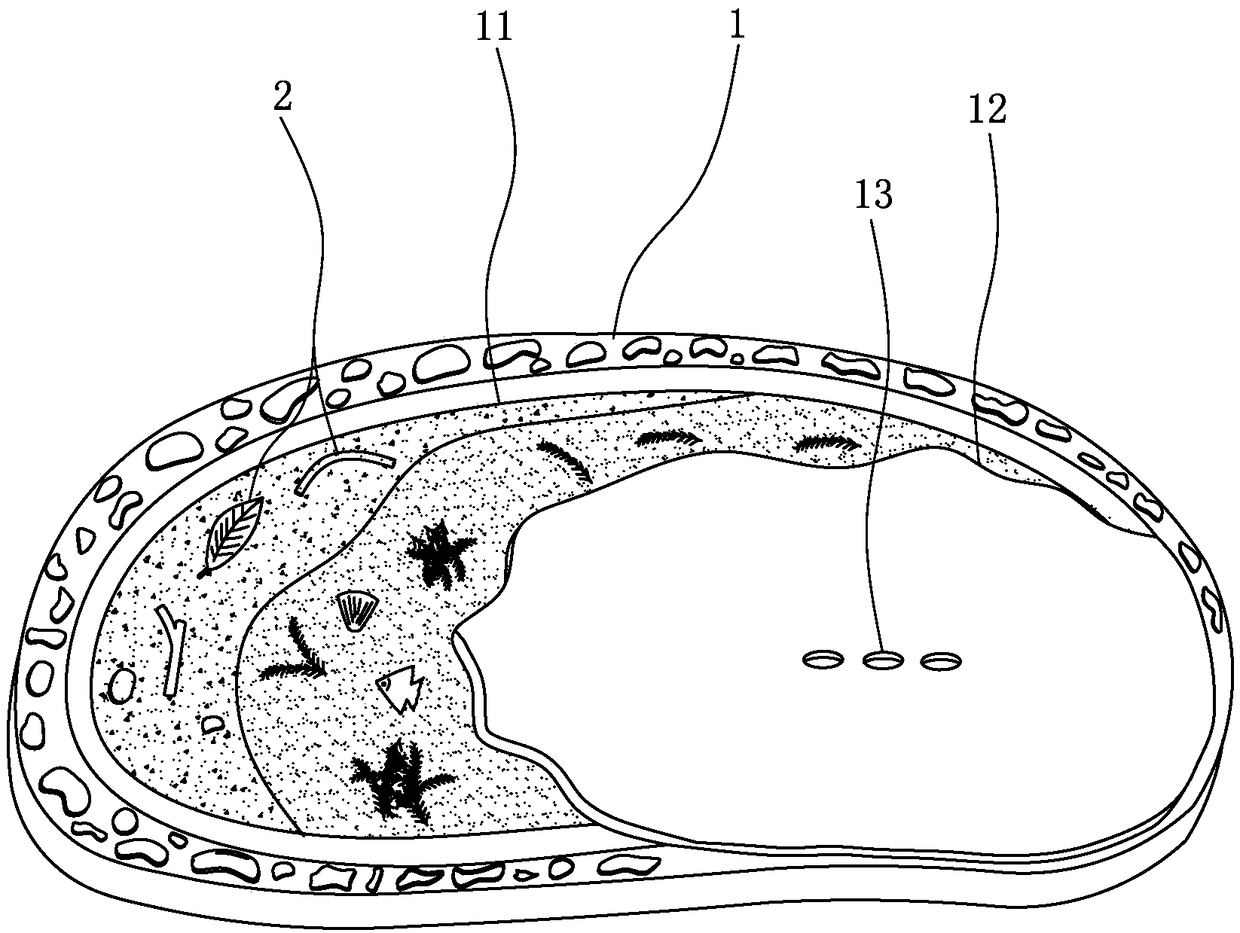

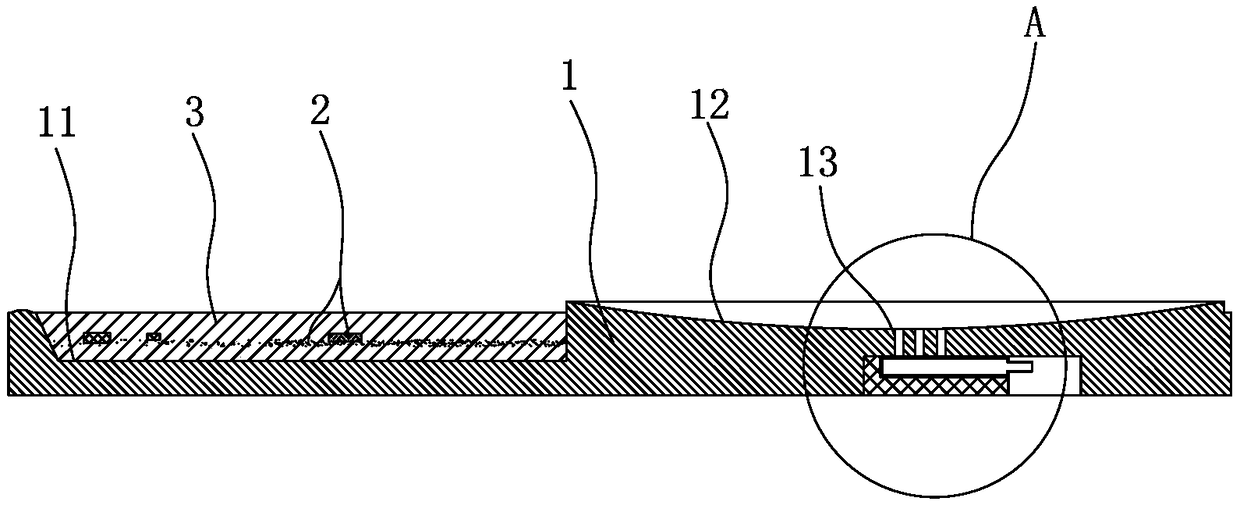

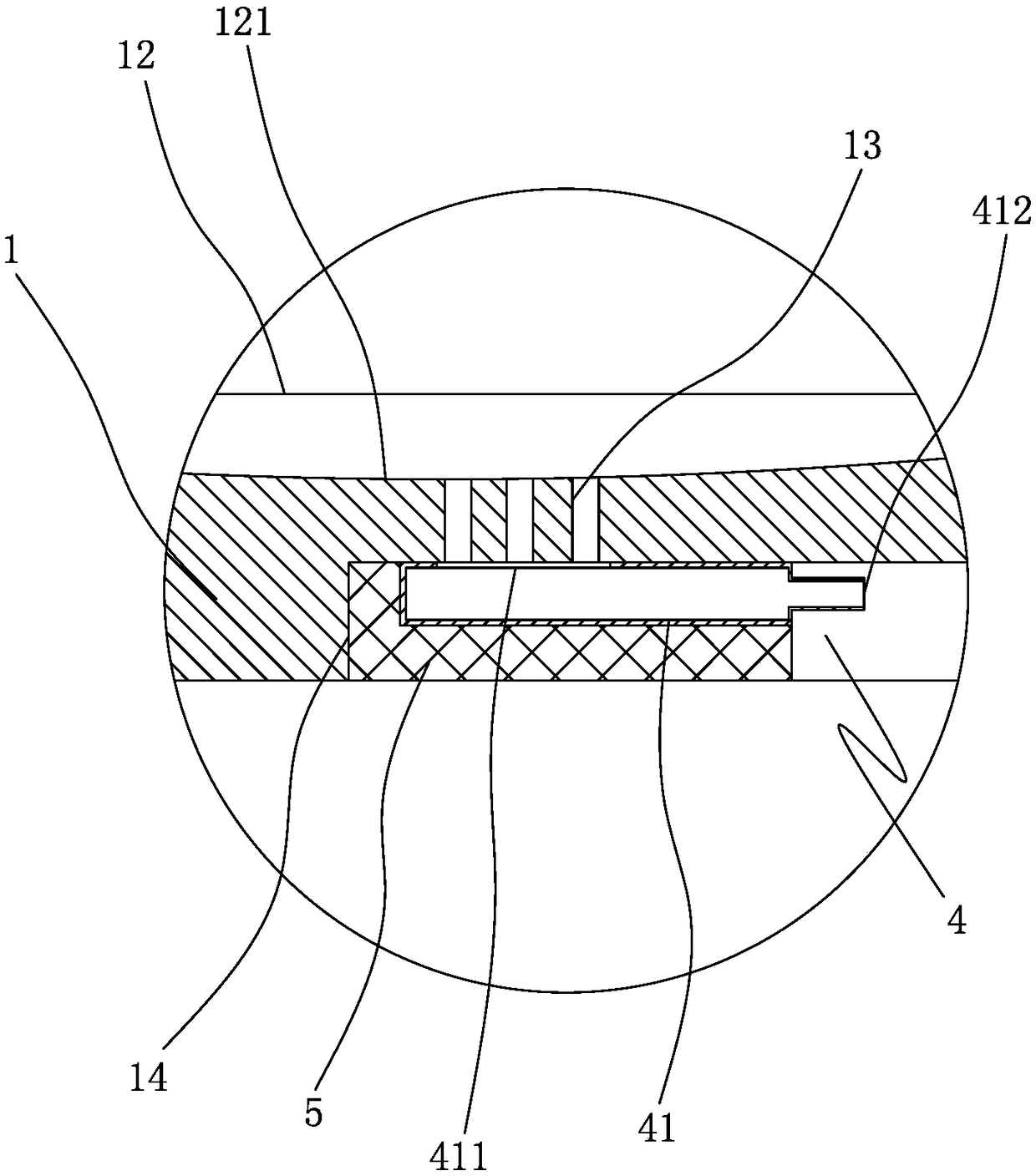

[0047] (1) Select the raw material of the tea tray, and carve, shape and polish it to obtain a blank with landscaping grooves 11;

[0048] (2) burn the edge of the blank and the tea making area 12 to increase the rough feel of the surface;

[0049] (3) Coat the surface of the blank with waterproof material and let it dry naturally for 24 hours;

[0050] (4) Pouring a layer of transparent colloid A in the landscaping groove 11, and fixing and pasting the landscaping material 2 on the transparent colloid A, and drying at 70° C. for 12 hours at a time;

[0051] (5) Pouring a layer of transparent colloid B on the surface of the dried transparent colloid A, casting the transparent colloid B to cover the landscaping groove 11, and drying for a second time at 70°C for 12 hours to obtain a tea tray.

[0052] Specifically, the components of the transparent colloid A and the transparen...

Embodiment 2

[0057] The manufacturing process of the landscaping tea tray includes the following steps in turn:

[0058] (1) Select the raw material of the tea tray, and carve, shape and polish it to obtain a blank with landscaping grooves 11;

[0059] (2) Coat the surface of the blank with waterproof material and let it dry naturally for 48 hours;

[0060] (3) Pouring a layer of transparent colloid A in the landscaping groove 11, and fixing and pasting the landscaping material 2 on the transparent colloid A, and drying at 65° C. for 14 hours at a time;

[0061] (4) Pouring a layer of transparent colloid B on the surface of the dried transparent colloid A, casting the transparent colloid B to cover the landscaping groove 11, and drying for a second time at 75°C for 10 hours to obtain a tea tray.

[0062] Specifically, the components of the transparent colloid A and the transparent colloid B are the same, and further, the transparent colloid A and the transparent colloid B are both glass-p...

Embodiment 3

[0067] The manufacturing process of the landscaping tea tray includes the following steps in turn:

[0068] (1) Select the raw material of the tea tray, and carve, shape and polish it to obtain a blank with landscaping grooves 11;

[0069] (2) Coat the surface of the blank with waterproof material and let it dry naturally for 36 hours;

[0070] (3) Pouring a layer of transparent colloid A in the landscaping groove 11, and fixing and pasting the landscaping material 2 on the transparent colloid A, and drying at 75° C. for 14 hours at a time;

[0071] (4) Pouring a layer of transparent colloid B on the surface of the dried transparent colloid A, casting the transparent colloid B until it covers the landscaping groove 11, and drying it naturally for 24 hours to obtain a tea tray.

[0072] Specifically, the components of the transparent colloid A and the transparent colloid B are the same, and further, the transparent colloid A and the transparent colloid B are both transparent e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com