Dental implant guide plate based on 3D printing and manufacture method thereof

A 3D printing and dental implant technology, which is applied in the fields of dental implants, dentistry, and dental restorations, can solve the problems of unfavorable implant guides and accurate positioning, and achieve the effect of not being easy to move, reducing gaps, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

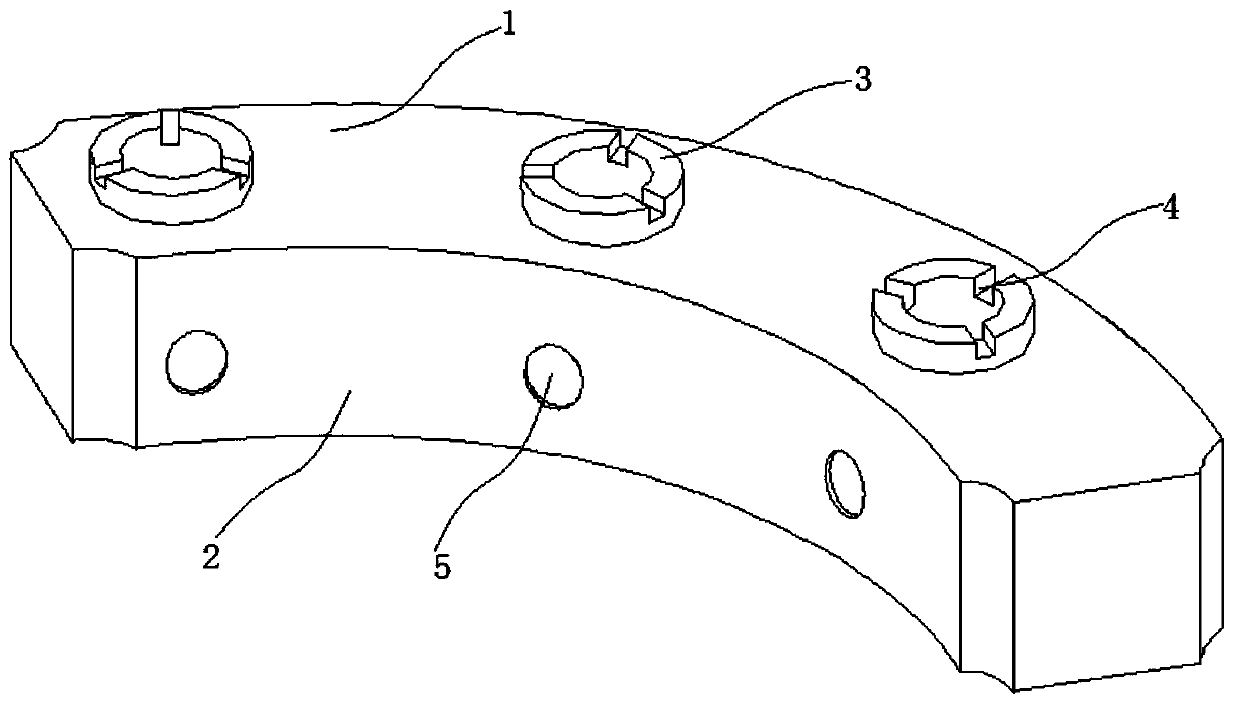

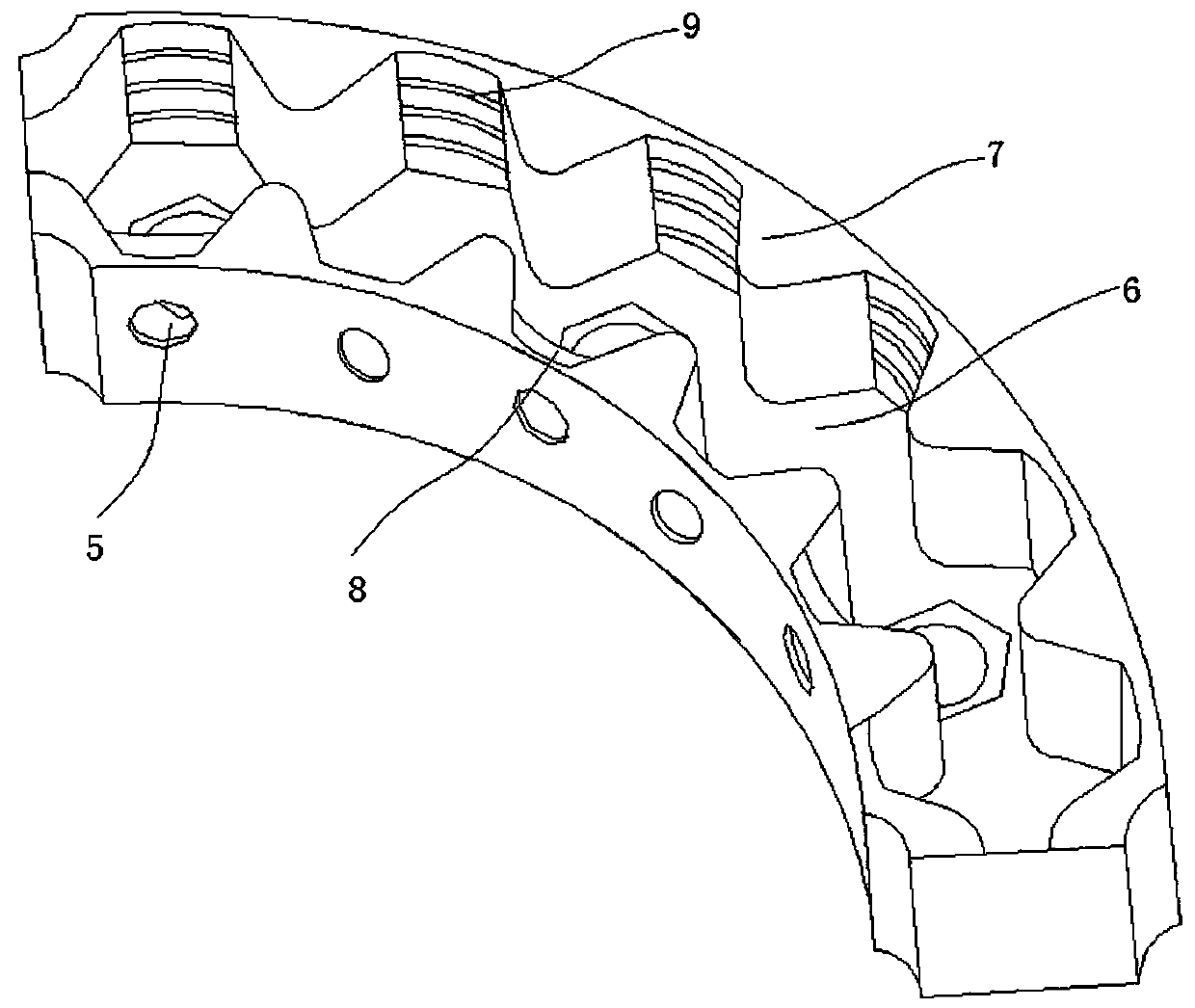

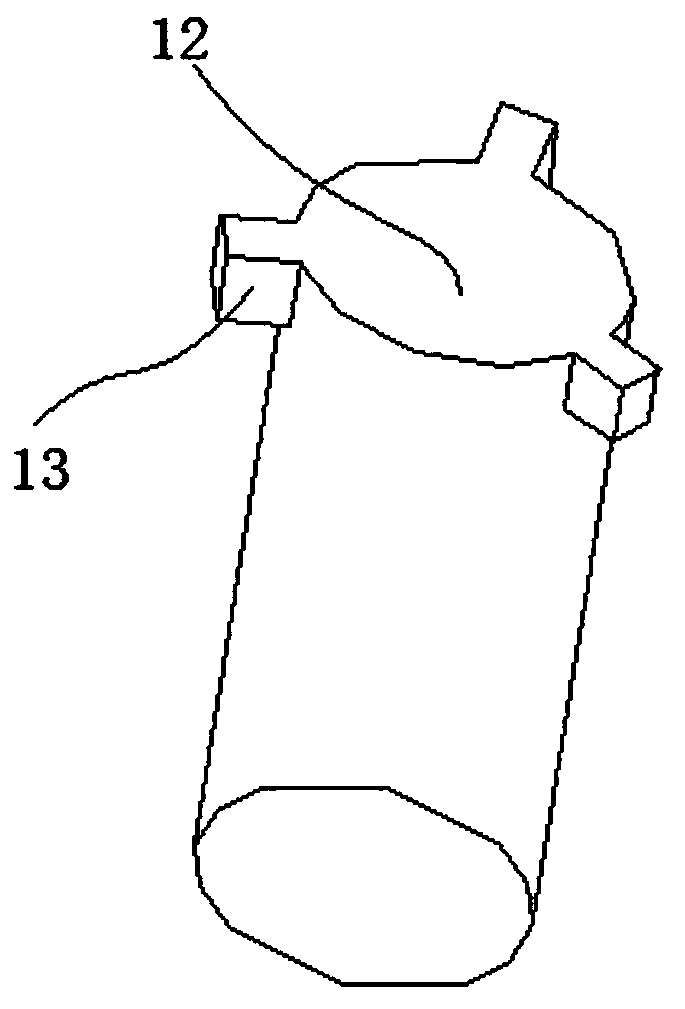

[0038] Such as figure 1 As shown, the present invention specifically discloses a dental implant guide plate based on 3D printing, including a base body and a guide hole 3. Before the tooth is implanted, it is necessary to drill holes on the bone wrapped in the gums. By relatively fixing the base body and the gums, And the guide hole is aligned with the part where the tooth needs to be implanted, and then relevant medical tools are used to drill holes from the guide hole into the bone.

[0039] The base body includes a positioning part 1 for opening...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com