Automatic grouting machine of pedestal pan

An automatic grouting and toilet technology, which is applied to ceramic molding machines, unloading devices, manufacturing tools, etc., can solve the problems of long operation time, many chores for wet billets, and high labor intensity, so as to avoid many chores and achieve the level of automation High, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

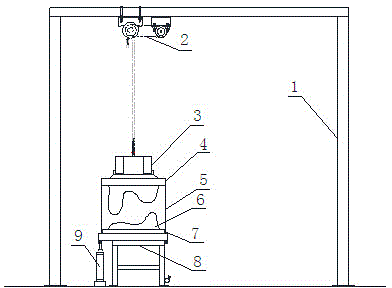

[0026] Combine below Figure 1 to Figure 6 The present invention is further described, but these examples do not constitute any limitation to the present invention.

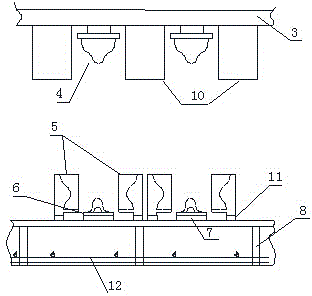

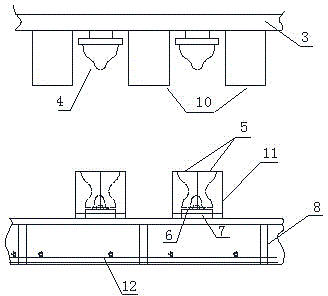

[0027] A toilet automatic grouting machine, see attached figure 1 , attached figure 2 , consisting of upper mold 4 and upper mold lifting mechanism 2, side mold 5 and side mold pressing device 10, bottom mold 6 and bottom mold frame 7, main line 8 and main line tilting device 9, moving beam 3, and frame 1;

[0028] The upper mold lifting mechanism 2 is a hoist, fixed on the top of the frame 1;

[0029] The side mold pressing device 10 is a cuboid air bag pressing device, and the upper mold 4 is alternately fixed on the moving beam 3 from left to right; the air bag can directly press the side mold 5 to prevent grout leakage during grouting.

[0030] The upper mold 4 is in the shape of a gourd, and there are two in total, which are respectively placed in the middle of the cuboid airbag pressing device;

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com