Method for fast making digital implantation guide plate and special positioning jaw frame for implementing method

A positioning frame and guide plate technology, which is applied in the fields of dental implants, medical science, dentistry, etc., can solve the problems of long production period and high cost of implant guide plates, and achieve the effects of easy promotion and application, low cost, and easy mastery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Take the model material silicone rubber or alginate in dentistry, take the impression of the standard tooth, put 10% barium sulfate into the self-coagulating tooth powder, add an appropriate amount of self-coagulating dental tray water for mixing, and then pour it into In the impression of standard teeth, take out and trim after solidification, and remove the excess part to obtain barium-containing dentures;

[0039]2. For patients with complete edentulousness, a plaster model of the patient's teeth is routinely obtained, wax plates and wax strips are laid on the plaster model, barium-containing dentures are installed, and then removed from the plaster model to become wax-based or resin-based For patients with partial denture loss, partial barium dentures with wax base or resin base can be made, and the method of making partial barium dentures is similar to that of patients with complete edentulous Same, but partial barium dentures can also be made without;

[0040]...

Embodiment 2

[0050] Steps 1, 2, 3, 4, 5, 6, 8, and 9 are carried out according to Example 1;

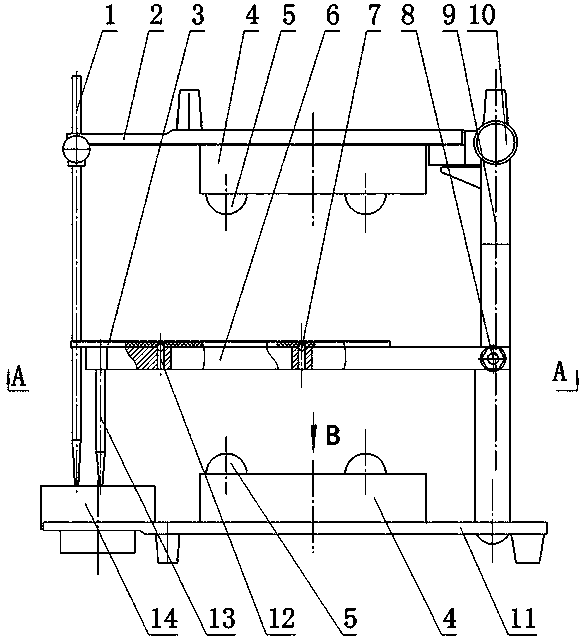

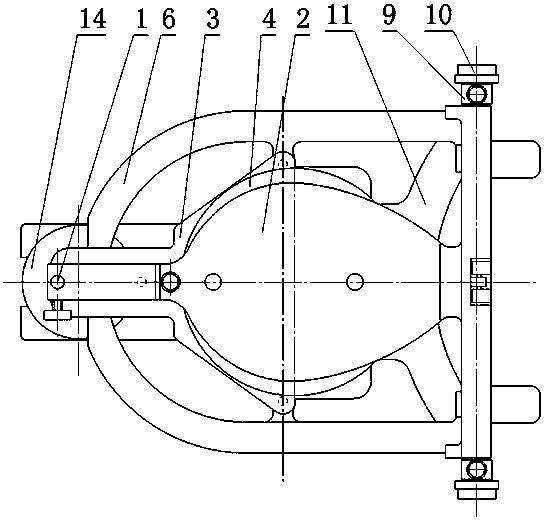

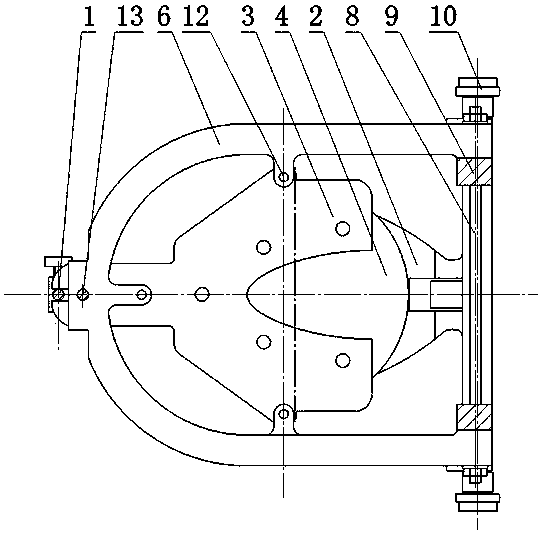

[0051] 10. Import the three-dimensional position data of the implant designed by the implant guide plate design device into the control system of the five-axis cutting equipment, and then fix the plaster model on the fixture of the five-axis cutting equipment. The selection of the drill diameter of the five-axis cutting equipment and the metal catheter The outer diameter is consistent, and the five-axis cutting equipment makes the planting positioning guide hole on the plaster model according to the planting position designed by the planting guide plate design device, that is, the planting positioning guide hole is processed on the plaster model;

[0052] 11. After the plaster model has finished making the guide hole, place a metal rod of corresponding diameter in the guide hole of the plaster model, put on the corresponding metal conduit, and make a planting guide plate on the plaster model by pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com