Construction Method of Prestressed Anchor Cable Grouting and Anchor in Cracked Rock and Soil Strata

A prestressed anchor cable and construction method technology, applied in excavation, infrastructure engineering, construction and other directions, can solve the problems of difficult construction, no review, high cost, low input construction cost, simple methods and steps, and easy processing and manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

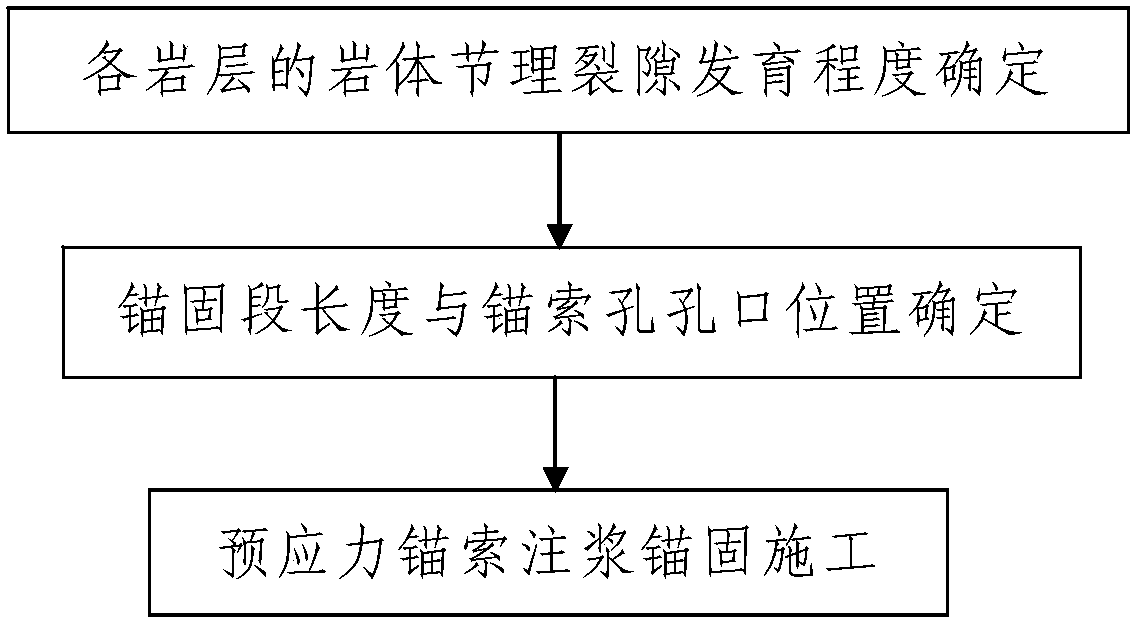

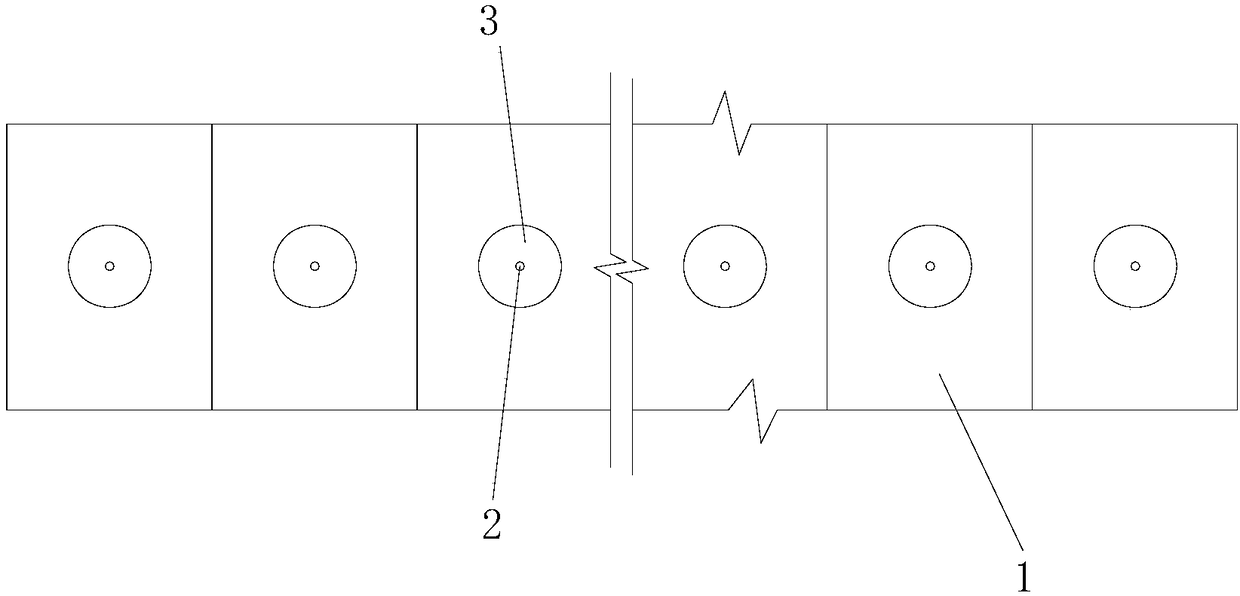

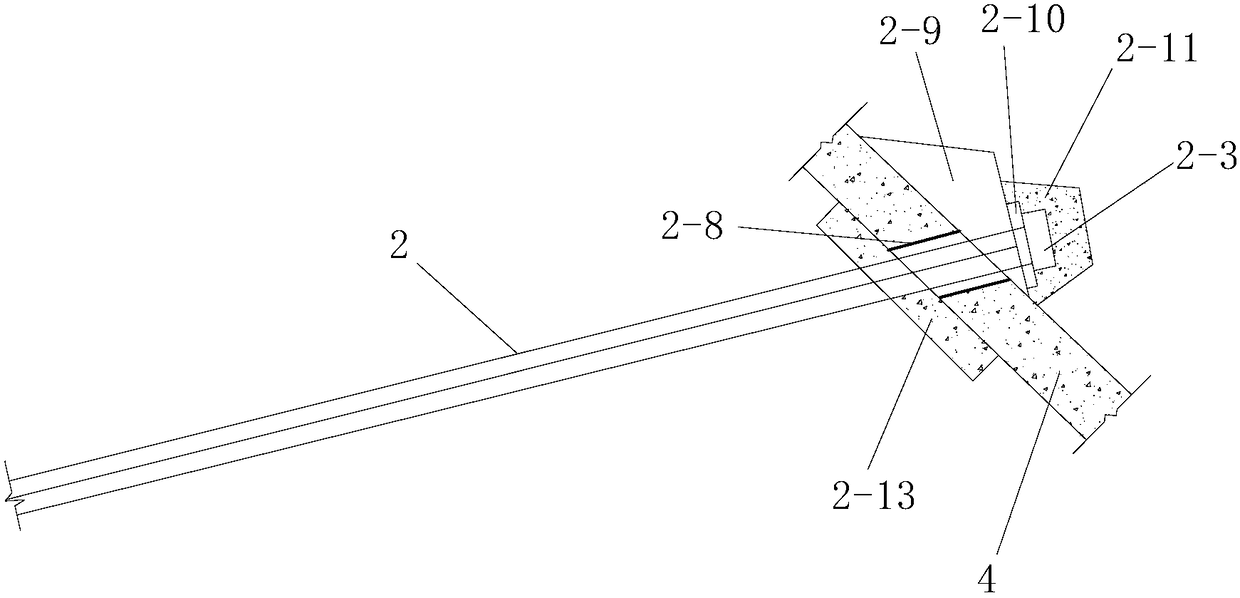

[0055] Such as figure 1 A kind of prestressed anchor cable grouting anchoring construction method shown in the cracked rock soil stratum adopts a plurality of prestressed anchor cables 2 arranged on the same plane to reinforce the slope 1 to be reinforced, and the plurality of prestressed anchor cables The structure and size of the cables 2 are the same and they are laid from left to right along the length direction of the slope 1 to be reinforced. The distance between two adjacent prestressed anchor cables 2 is 2.5m to 3.5m. For details, see Picture 1-1 ; The inclination angle A of the prestressed anchor cable 2=18°~22°, and the inclination angle A is the angle between the prestressed anchor cable 2 and the horizontal plane; using a plurality of the prestressed anchor cables 2 to treat the reinforced slope 1 When performing reinforcement, the following steps are included:

[0056] Step 1. Determination of the degree of development of rock mass joints and fissures in each ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com