Tunnel disease treatment method capable of achieving repeated grouting and applicable to special grout

A technology for repeated grouting and tunnel damage, which is applied to tunnels, tunnel linings, earthwork drilling and mining, etc., to achieve safe operations, improve construction speed, and avoid high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

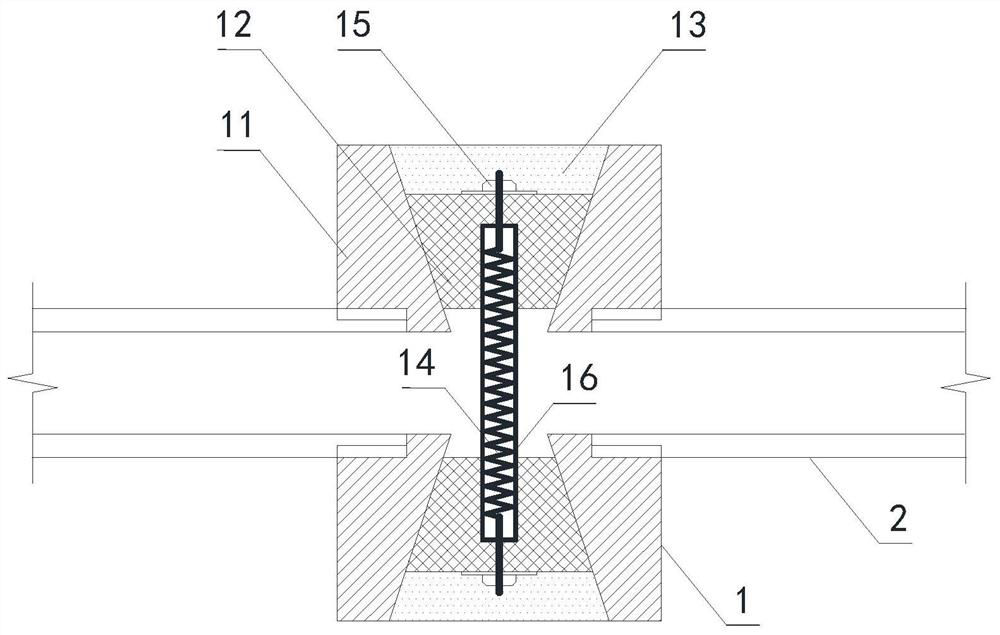

[0028] In the present invention, a tunnel disease treatment method that can repeat grouting and is applicable to special grout, the treatment method is as follows:

[0029] Step 1. Before and after the section where water leakage is prone to occur in the tunnel, between the initial support and the waterproof layer of the tunnel, set multiple sets of repeatable grouting component groups along the longitudinal interval of the tunnel; two adjacent sets of repeatable grouting component groups The interval between them is 5-10m. A reinjectable component group includes a plurality of reinjectable components, including:

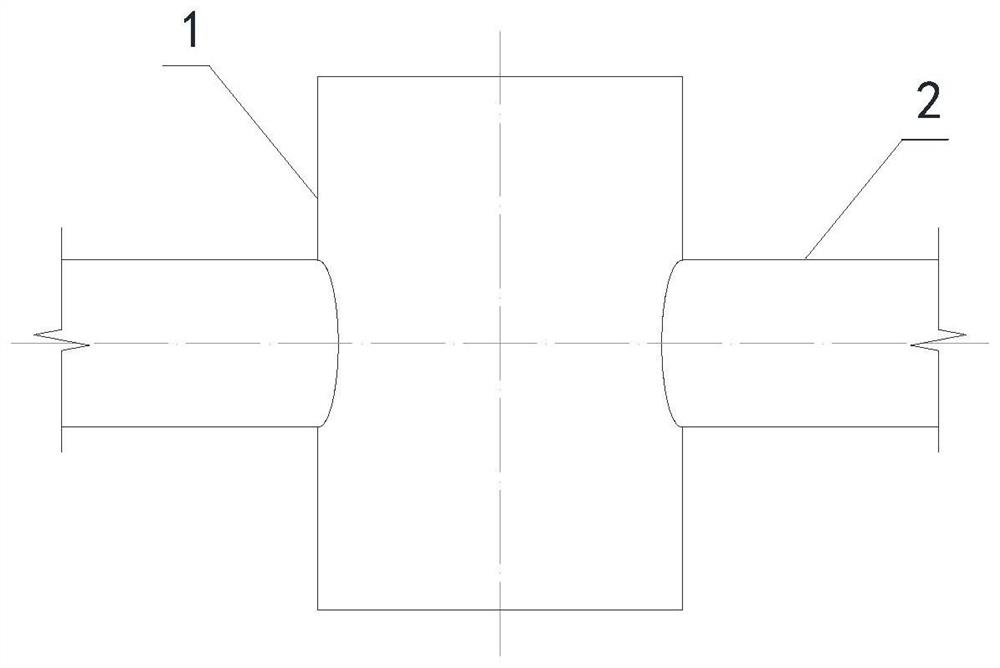

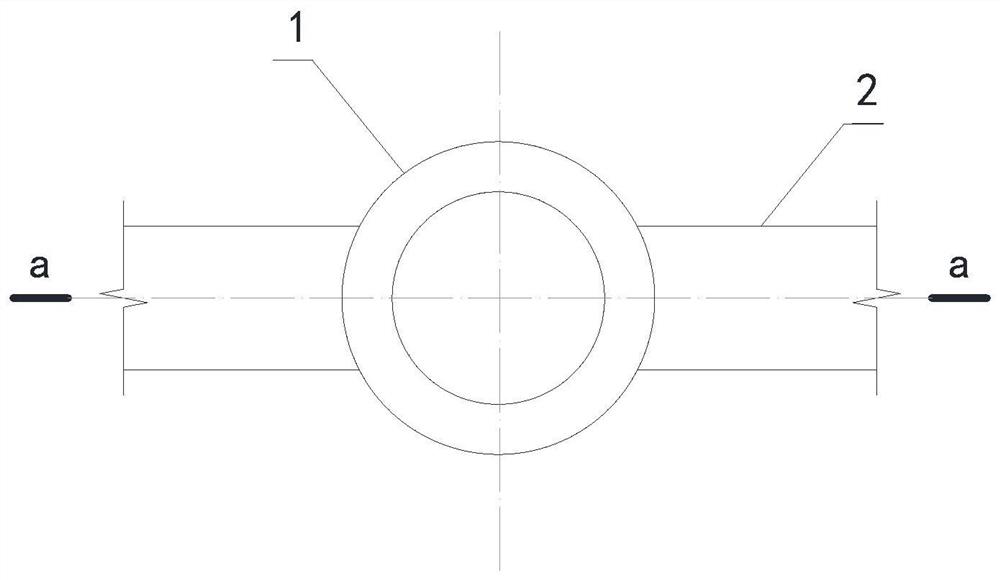

[0030] The overflow cylinder 1 is a cylinder with both ends open, and its internal cavity is composed of an inverted round platform cavity and a perfect circular platform cavity connected up and down, and a connected cylindrical cavity is integrally connected between the inverted round platform cavity and the perfect circular platform cavity. Each cavity is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com