Test optimization method for pre-tightening force of ball screw of feeding system of numerical control machine tool

A feed system, ball screw technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as difficulty in reuse, and achieve the effect of accurate and simple pre-tightening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following, an experimental optimization method for the pretightening force of a ball screw of a feed system of a CNC machine tool according to the present invention will be described in detail in combination with the embodiments and the accompanying drawings.

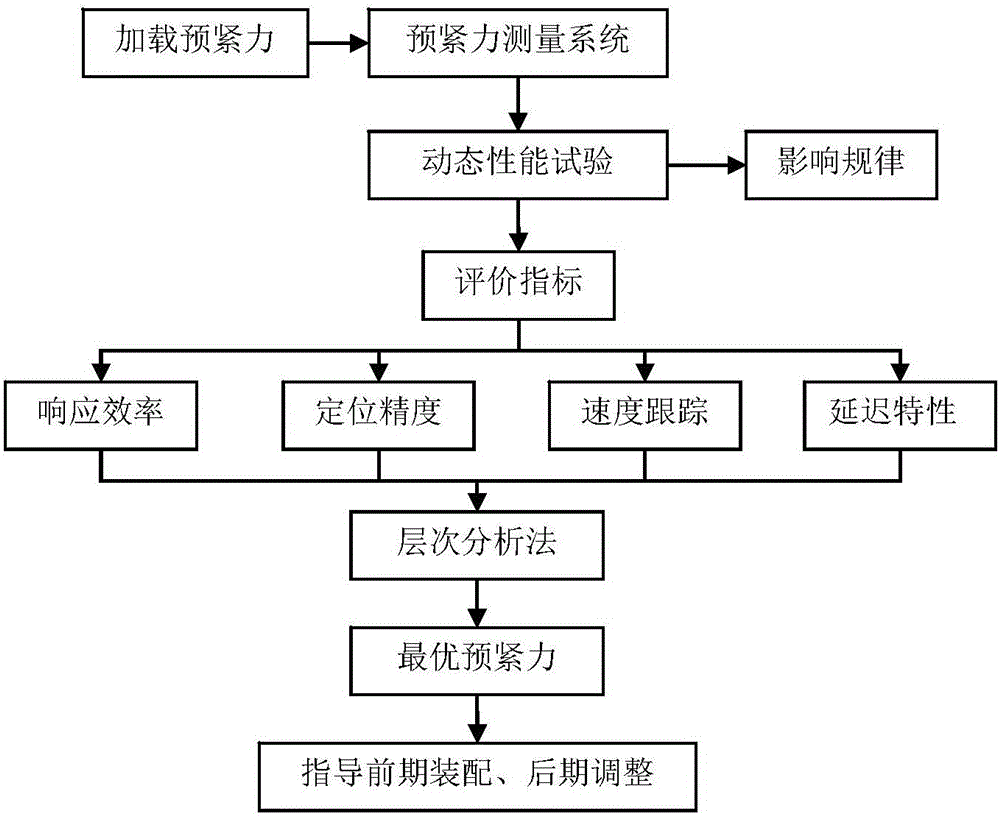

[0034] Such as figure 1 Shown, the test optimization method of a kind of CNC machine tool feed system ball screw preload of the present invention comprises the following steps:

[0035] 1) Build as figure 1 Ball screw preload measuring system shown;

[0036] Step 1) described in setting up the ball screw preload measuring system, including:

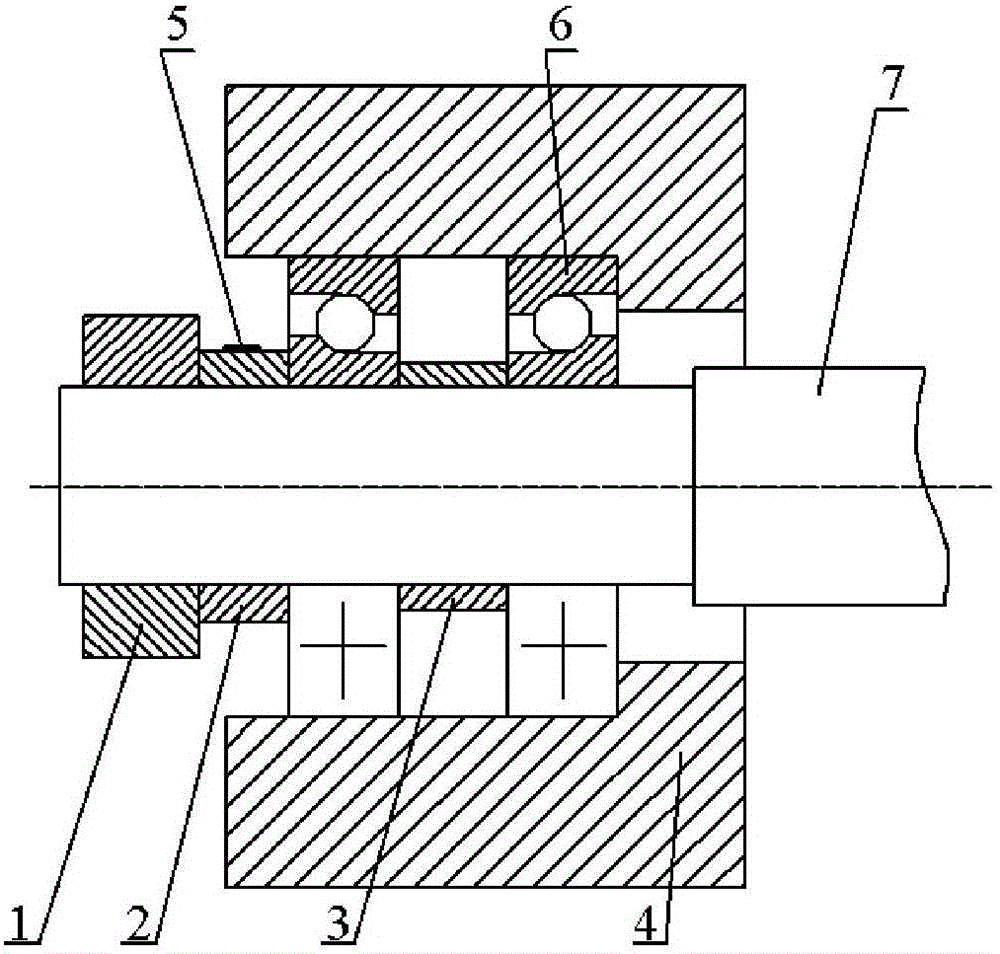

[0037] (1) Design a suitable elastic sleeve 2 according to the diameter specification of the ball screw, and install the elastic sleeve 2 between the lock nut 1 and the bearing 6;

[0038] The elastic bushing 2 should be designed according to the diameter of the ball screw 7 and the inner diameter of the bearing seat 4. The inner diameter of the elastic bushing 2 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com