Electric synchronous loader

A synchronous loader and electric technology, applied in the field of loader, can solve the problems such as the inability to realize the no-load start of the test device to change the size and direction of the load, the limited loading stroke angle of the external force transmission line, and the large size of the loading torque. Excellent starting performance, compact structure and low power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

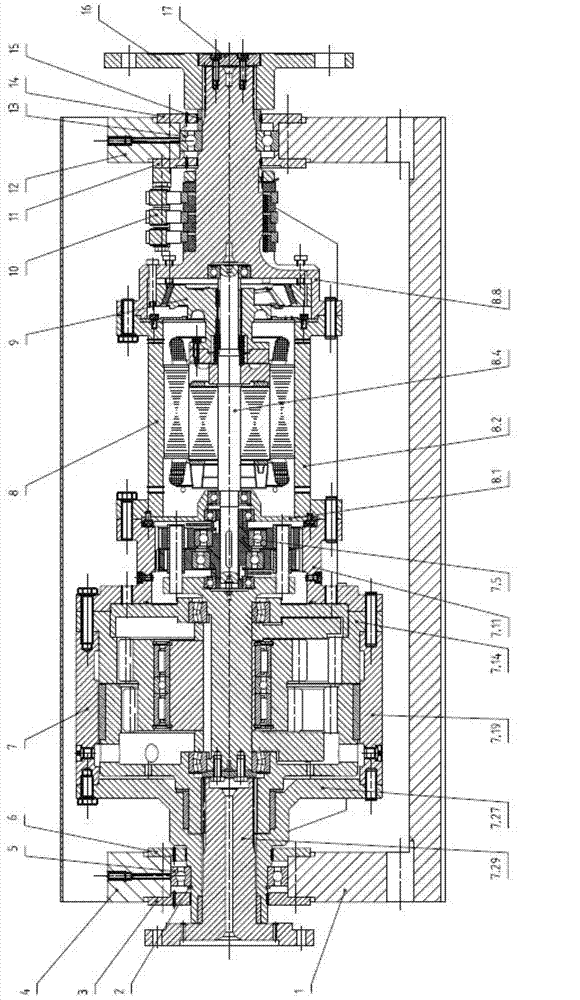

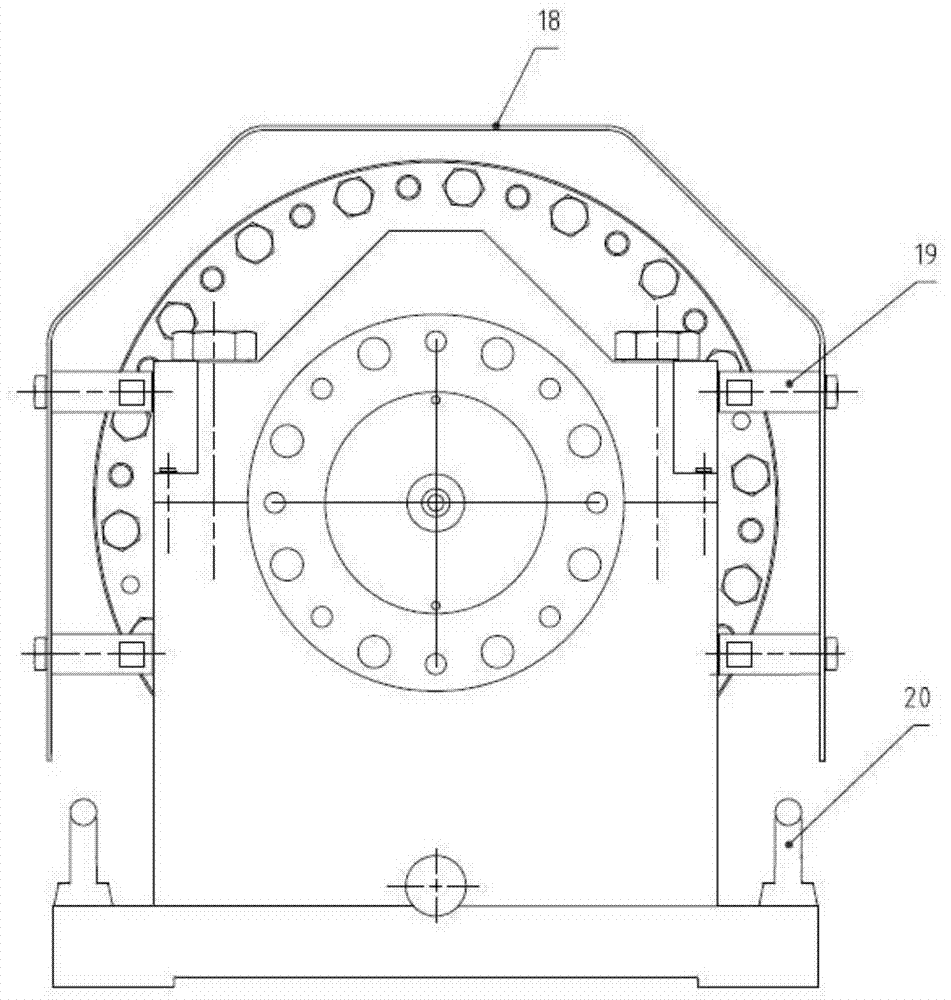

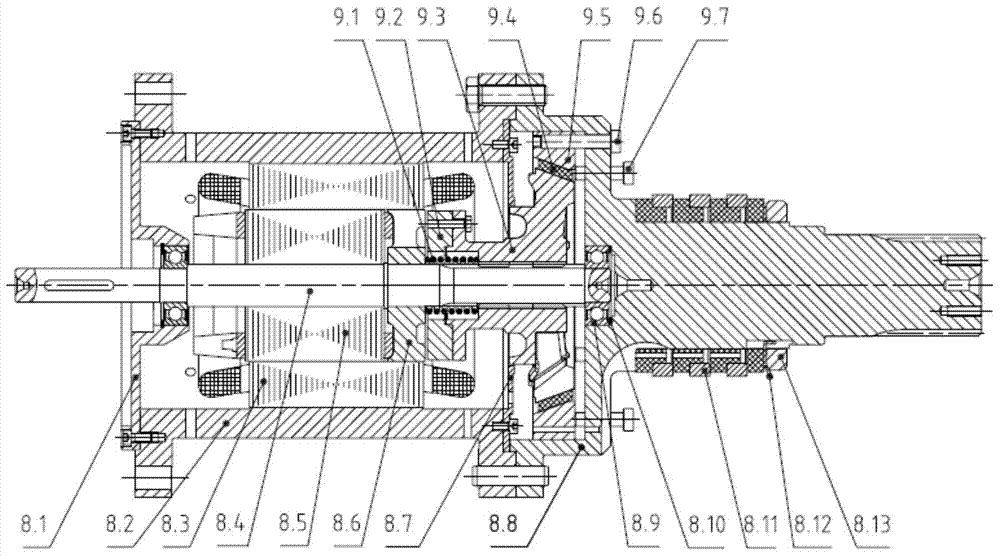

[0052] The invention provides an electric synchronous loader including a base 1, a snap ring 2, a first left end cover 3, a first bearing gland 4, a first rolling bearing 5, a first right end cover 6, a reducer 7, a loading motor 8, and a brake 9. Brake frame assembly 10, second left end cover 11, second bearing gland 12, second rolling bearing 13, second right end cover 14, bushing 15, flange 16, pressure plate 17 and cover 18, see figure 1 as well as figure 2 .

[0053] The inner holes of the first left end cap 3, the first right end cap 6, the second left end cap 11 and the second right end cap 14 are all provided with sealed rectangular grooves, and the inner cavity is provided with air holes, which are divided into two parts after integral processing. The structure is easy to install.

[0054] The brake 9 is installed in the inner cavity of the tail of the loading motor 8, and is integrated with the loading motor 8 to play the role of braking and load protection.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com