Annular prefabricated assembly beam plate type fan foundation and installation method

A prefabricated assembly, fan foundation technology, applied in infrastructure engineering, construction, etc., can solve problems such as damage, limited strength of assembly foundation, limited connection strength of prefabricated parts, etc., and achieve the effect of improving grouting quality and strengthening annular structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

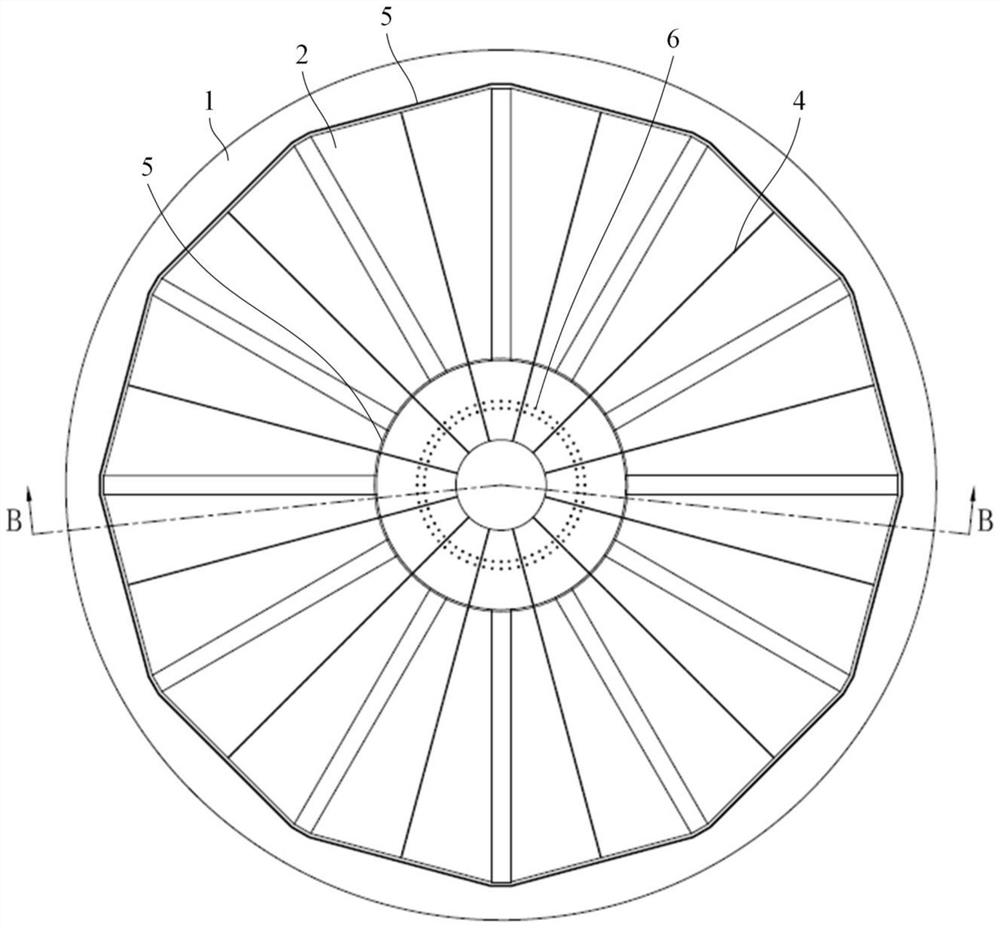

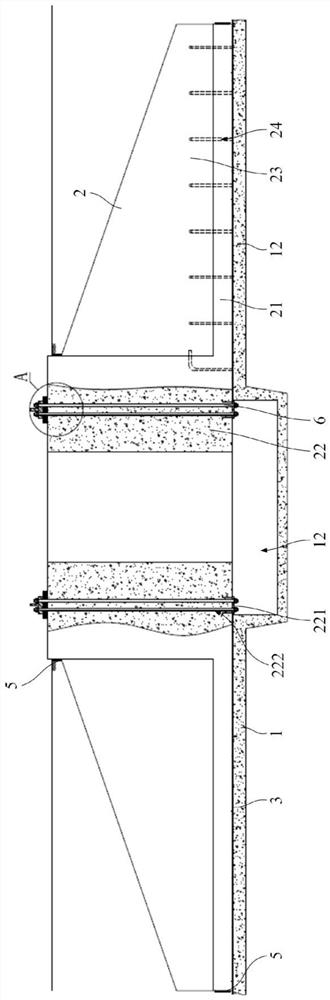

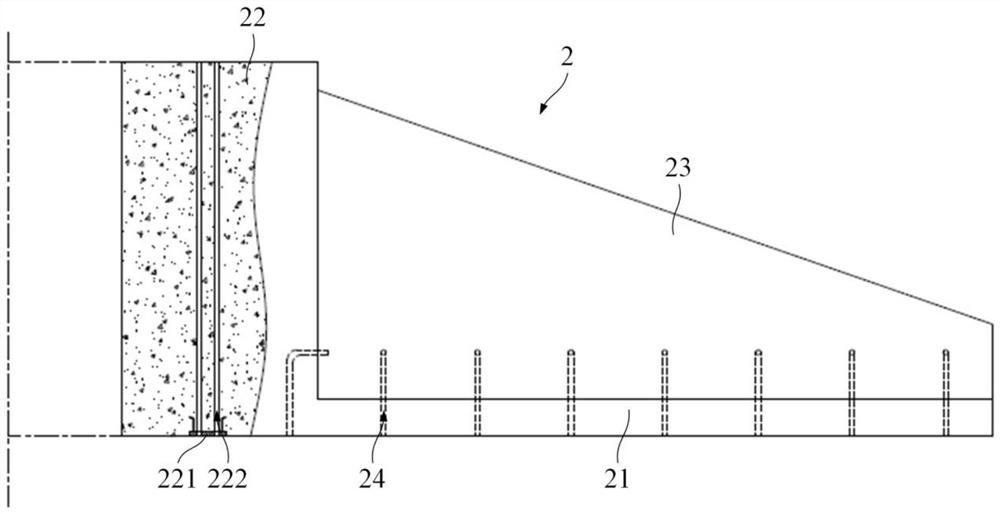

[0045] Embodiment 1, hoop prefabricated beam-slab fan foundation:

[0046] see Figure 1 to Figure 5 , the circumferential prefabricated beam-slab fan foundation in one embodiment includes a cushion layer 1, a prefabricated beam-slab unit 2, a bottom grouting body 3, a joint grouting body 4, a hoop prestressed cable 5 and an anchor bolt assembly 6, It can improve the overall strength of the assembled fan foundation and improve the anti-seismic capability of the fan foundation.

[0047] see Figure 1 to Figure 3 Specifically, the cushion layer 1 is poured at the bottom of the corresponding area of the wind turbine foundation. Cushion 1 is used to support the upper foundation components and finally support the fan system. It can be understood that the cushion layer 1 is generally poured on site at the bottom of the foundation pit. The thickness and material of the cushion layer 1 can be set according to needs, for example but not limited to, the thickness can be 50mm-250mm, ...

Embodiment 2

[0054] Embodiment 2, the installation method of the circumferential prefabricated beam-slab fan foundation:

[0055] According to the circumferential prefabricated and assembled beam-slab fan foundation in the above embodiment, the present invention also provides an installation method suitable for the above-mentioned circumferential prefabricated and assembled beam-slab fan foundation, so as to improve the construction efficiency of the fan foundation and ensure the construction of the fan foundation Quality; the installation method of the circumferential prefabricated beam-slab fan foundation in an embodiment includes the following steps:

[0056] S1: Cushion 1 construction. The cushion layer 1 is poured on site and maintained according to the area where the prefabricated beam-slab fan foundation is installed in the circumferential direction.

[0057] According to the circumferential prefabricated beam-slab fan foundation, the foundation pit is excavated at the construction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com