Lifting jack with lifting pre-tightening device and method for lifting jack for pre-tightening lifting steel strands

A steel strand and jack technology is applied in the field of prestressed auxiliary construction devices, which can solve the problems of cumbersome disassembly and installation work, lack of force, loss, etc., and achieve the effects of simple and feasible preloading method, improved safety, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

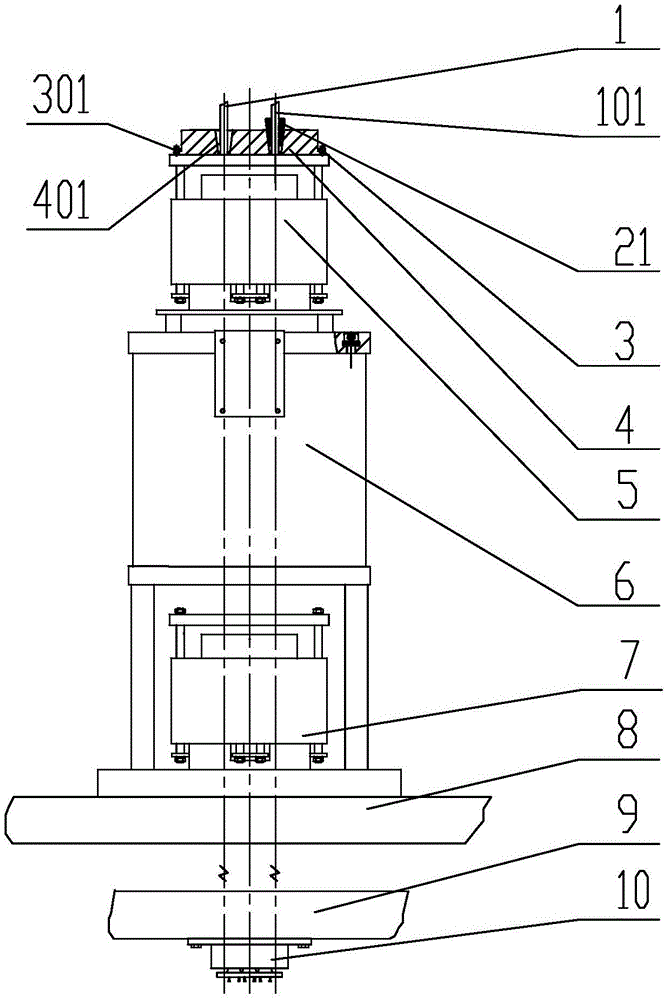

[0032] A lifting pretensioning device, the lifting pretensioning device is composed of an upper lifting clip 21, a pressure plate 3 and a pretensioning block 4 (see figure 1 ),

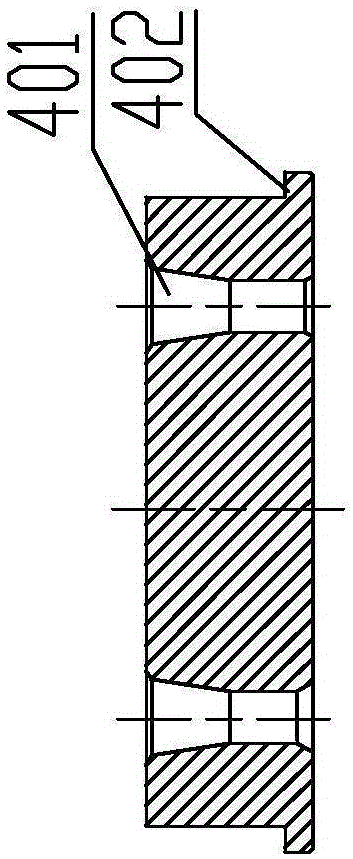

[0033] The pre-tightening block 4 is a short cylinder with a boss 402 at the bottom of the short cylinder, and there are n tapered holes 401 for installing the upper lifting clip 21 on the short cylinder, see diagram 2-1 , Figure 2-2 ;

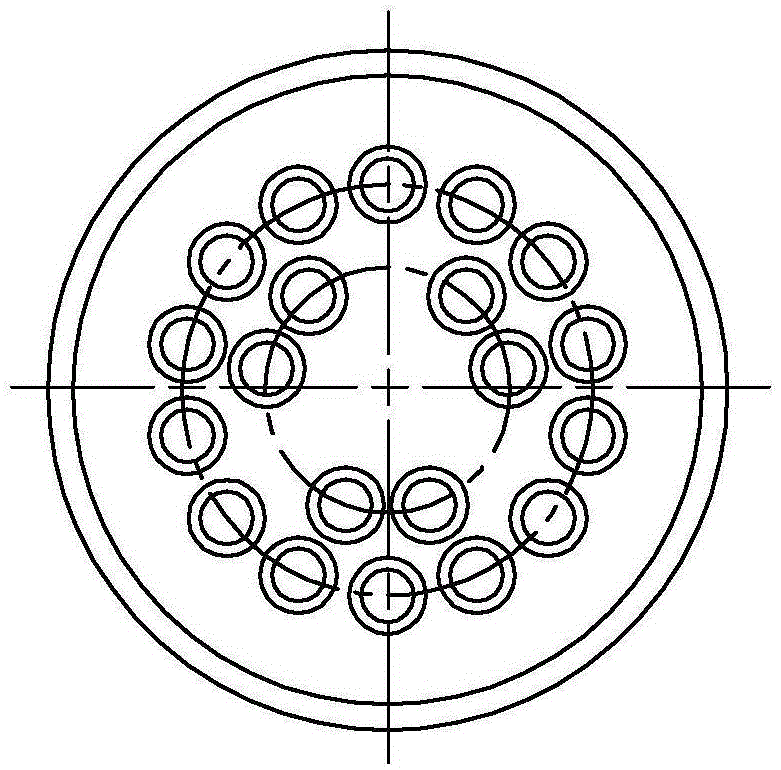

[0034] The pressure plate 3 used to connect the pre-tightening block and the upper clamping top is circular, and there are m through holes 301 on the circular ring, and there is an inner step 302 in the circular ring; see Figure 3-1 , Figure 3-2 ;

[0035] In the working state, the pre-tightening block 4 is fixedly installed on the upper clamping top 5 of the main top 6, and the upper lifting clip 21 is placed in the taper hole 401 of the corresponding pre-tightening block 4 of the steel strand 101 to be adjusted; The annular pressure plate 3 is located outsi...

Embodiment 2

[0040] A lifting jack with a lifting pretensioning device.

[0041] Such as figure 1 As shown, the lifting jack of the lifting and pre-tensioning device includes an upper clamping top 5, a main top 6 and a lower clamping top 7 connected in sequence, and a lifting and pre-tensioning device.

[0042] The lifting pretensioning device is the lifting pretensioning device described in the first embodiment, which is composed of an upper lifting clip 21, a pressure plate 3 and a pretensioning block 4 (see figure 1 ),

[0043] In the working state, the pre-tightening block 4 is fixedly installed on the upper clamping top 5 of the main top 6, and the upper lifting clip 21 is placed in the taper hole 401 of the corresponding pre-tightening block 4 of the steel strand 101 to be adjusted; The annular pressure plate 3 is located outside the pretension block 4, the inner step 302 of the annular pressure plate 3 is stuck on the boss 402 of the pretension block 4, and the bolts and washers p...

Embodiment 3

[0045] A method for pre-tightening a steel strand, which uses the lifting jack with a lifting pre-tightening device described in Embodiment 2 to realize pre-tensioning of a certain steel strand during the process of synchronous lifting of heavy objects by the lifting jack. tight way.

[0046] When the lifting jack with the above-mentioned lifting pretensioning device is used to lift heavy objects, the connection method between the jack and the heavy object is the same as that of the ordinary lifting jack. The upper clamping top 5, main top 6 and The lower clamping top 7 is sequentially connected and installed on the load-bearing member, the pre-tension block 4 is fixedly installed on the upper clamping top 5 of the main top 6, and the upper lifting clip 21 is placed on the corresponding pre-tensioner of the steel strand 101 to be adjusted. In the taper hole 401 of the tight block 4; the annular pressure plate 3 is located outside the pre-tension block 4, and the bolts and washer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com