Actuator, in particular for a motor vehicle

A servo drive, drive shaft technology, applied in transmissions, transmission parts, gear transmissions, etc., can solve the problems of increasing component costs and assembly costs, and achieve the effect of improving service life and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

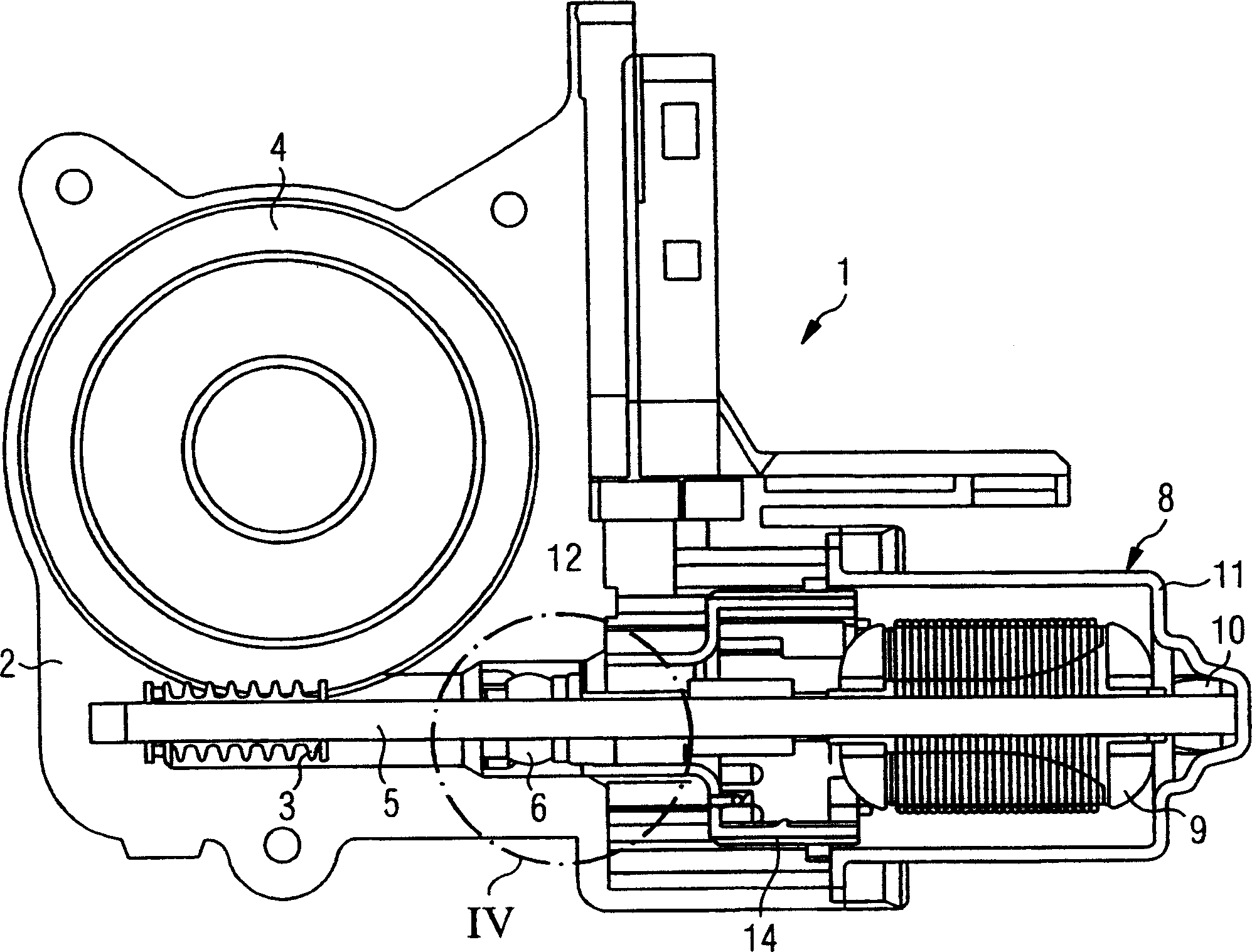

[0040] figure 1 A sectional view of an exemplary actuating drive 1 with a gearbox unit 2 and a motor unit 8 is shown. The gearbox unit 2 has a gearbox housing 12 in which a worm wheel 4 is accommodated and a worm shaft 4 which engages in the worm wheel 4 . The motor unit 8 consists of a motor housing 11 , a rotor 9 accommodated therein with a drive shaft 5 , and a bearing housing 18 at the drive end of the motor unit 8 . The worm shaft 3 is situated on the free end of the drive shaft 5 , which is driven by the motor unit 8 and is partially accommodated in the motor housing 11 . On the motor side, the drive shaft 5 is guided in a bearing 6 opposite the gearbox unit 2 and in a motor end bearing 10 . exist figure 1 In the embodiment of the present invention, the drive shaft 5 is formed in one piece. A two-part embodiment of the drive shaft 5 is likewise conceivable, which has a motor shaft and a transmission shaft and a connection therebetween.

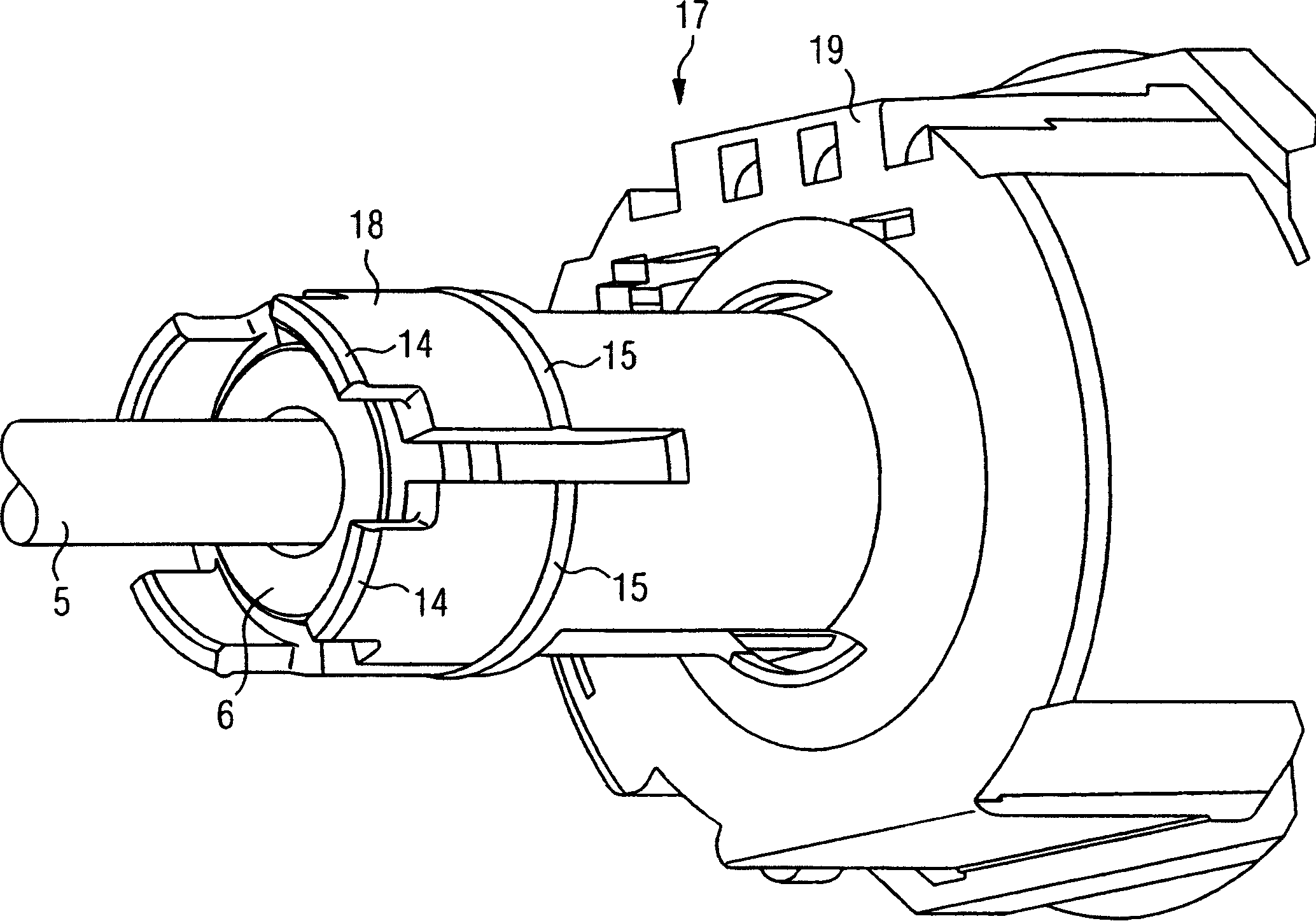

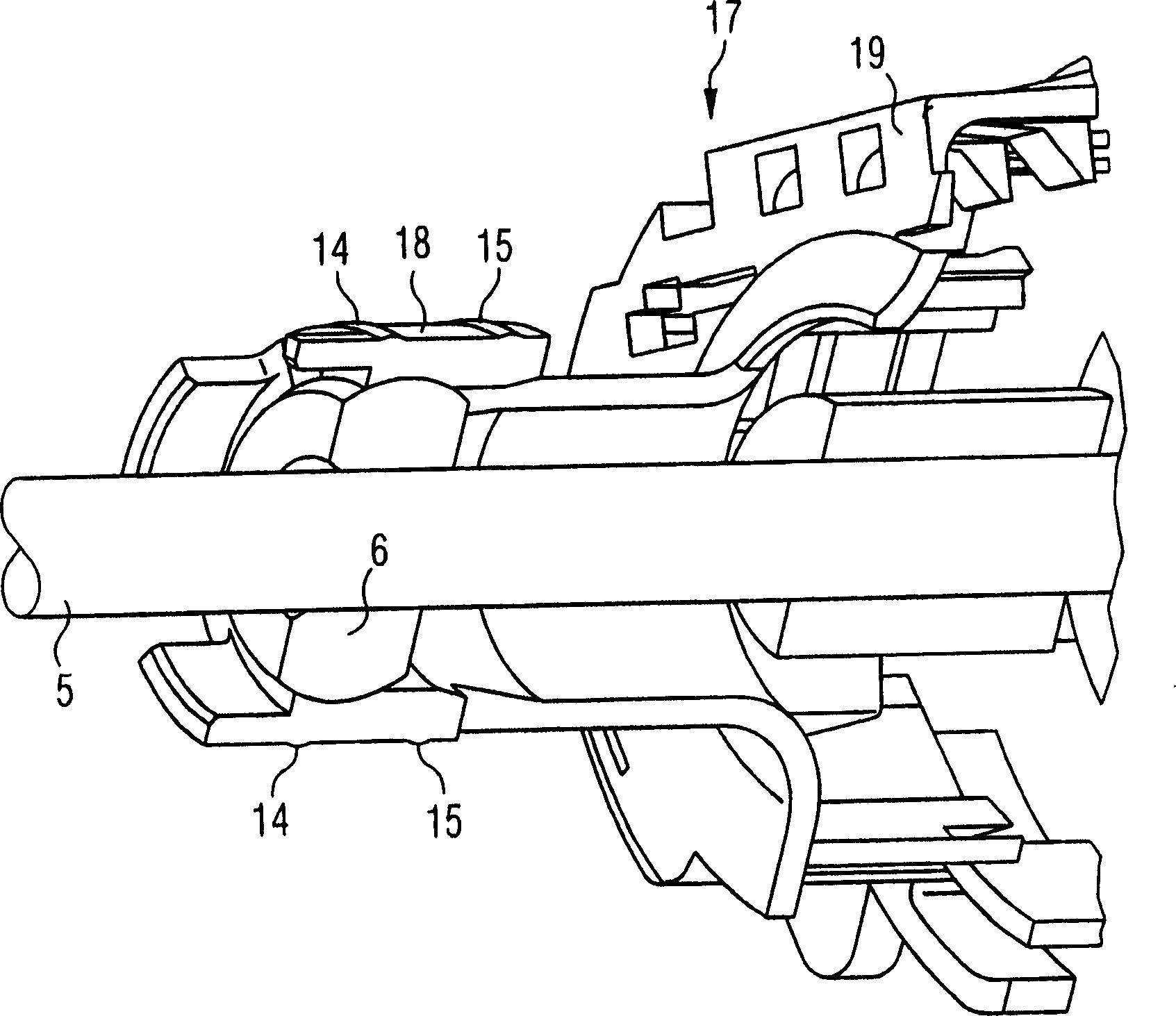

[0041] figure 2 shows a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com