Petrochemical conveying pipeline

A technology for transportation pipelines and petrochemical industry, which is applied in pipeline protection, pipeline heating/cooling, and pipeline protection through heat insulation, etc. Potential safety hazards, reduced sealing performance, uniform pre-tightening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

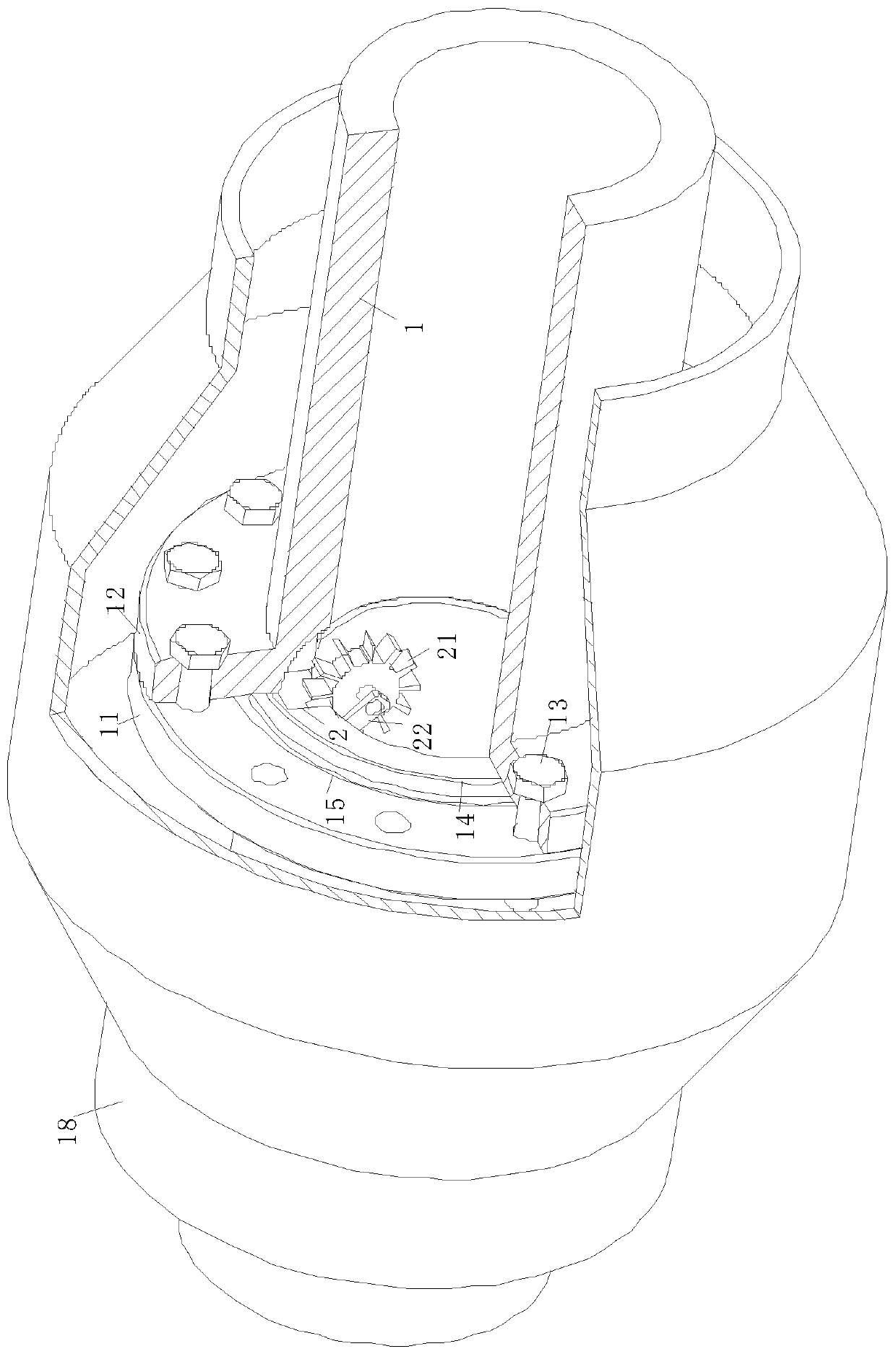

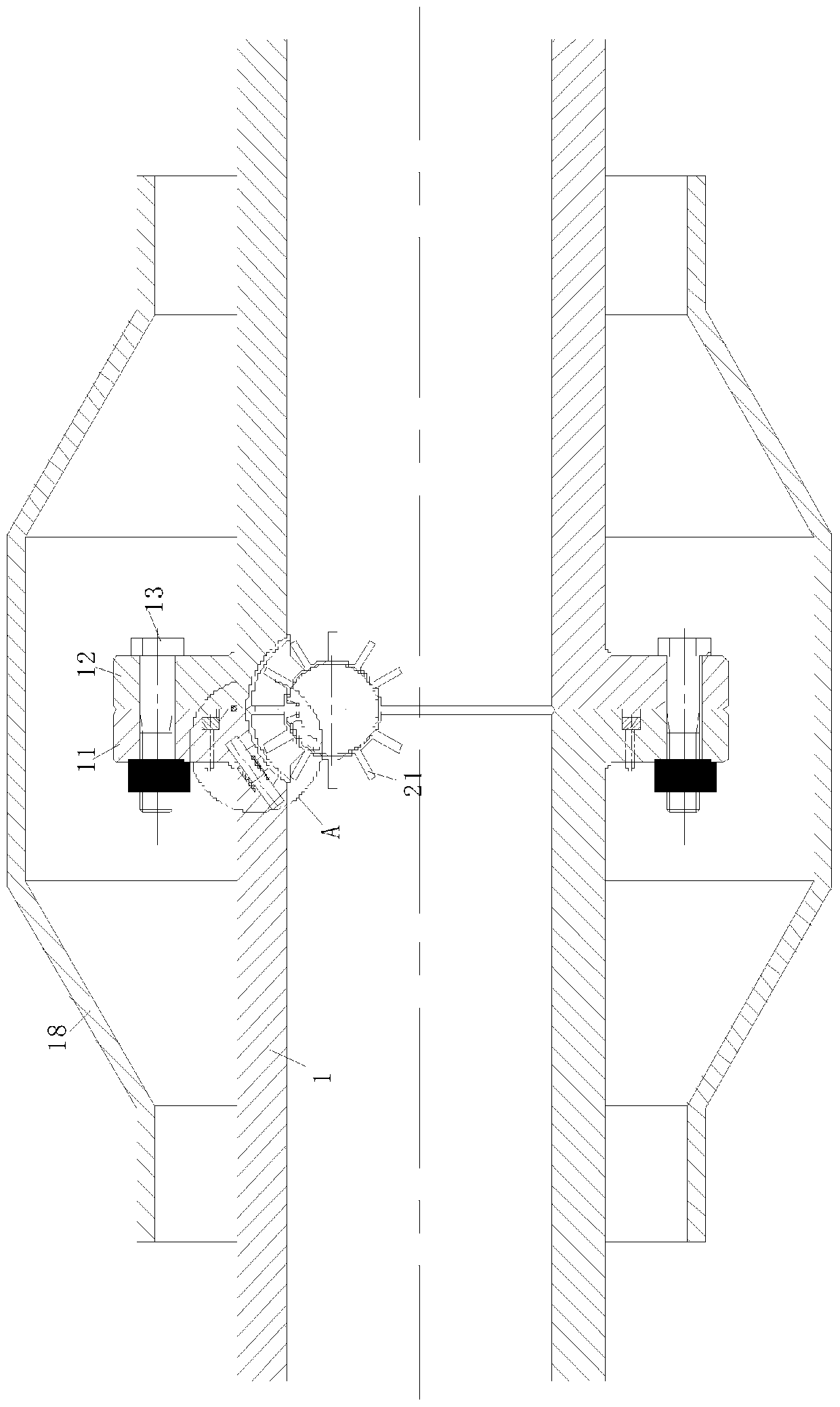

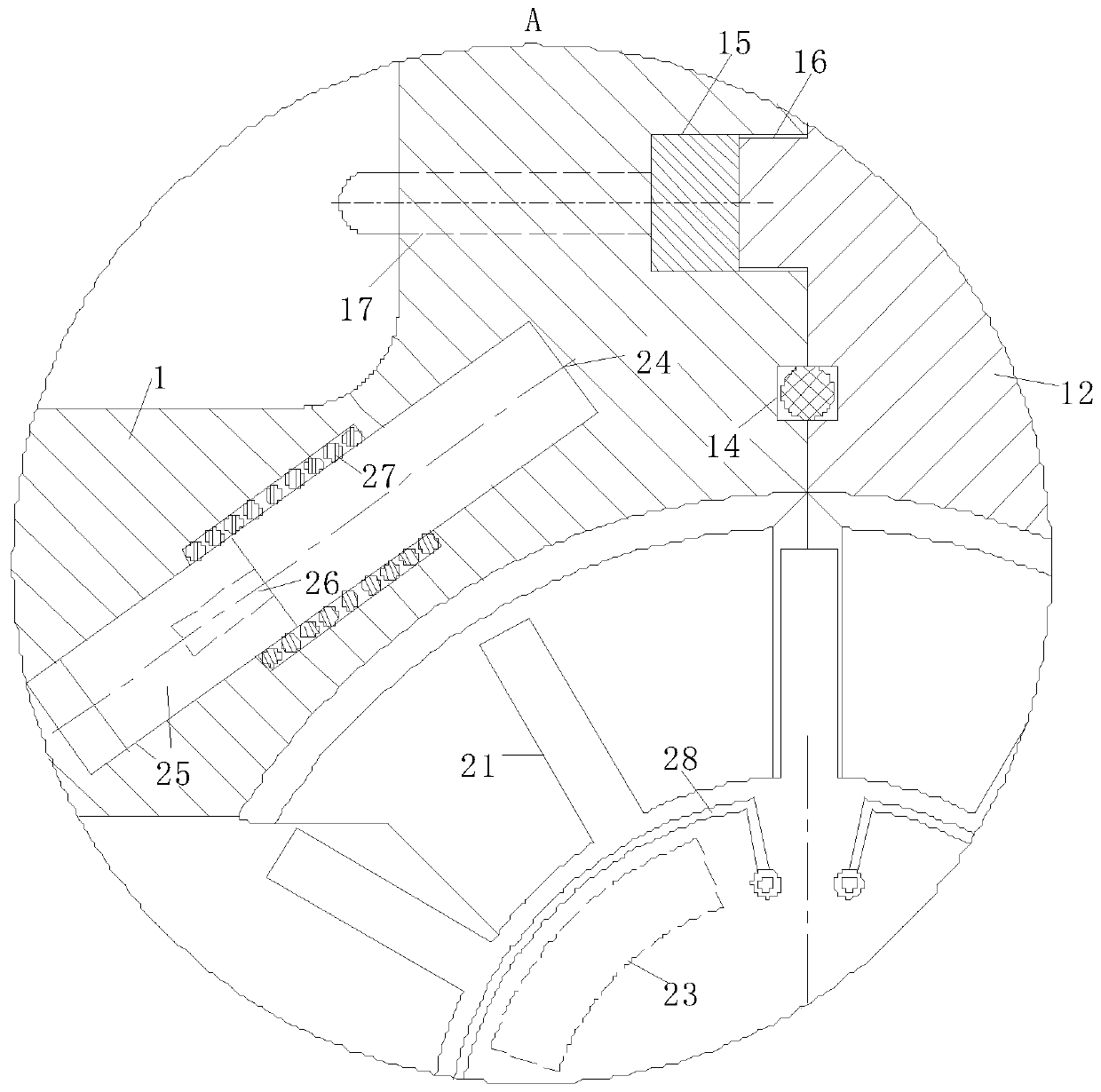

[0021] As an embodiment of the present invention, a group of overflow holes 17 are evenly distributed on the bottom circumference of the No. 2 sealing ring groove 15. The overflow holes 17 are used for the metal in the No. 2 sealing ring groove 15 to overflow after being squeezed. By observing the metal The height of the overflow ensures that the pre-tightening force of the bolt 13 is uniform; when the metal in the groove 15 of the second sealing ring is squeezed, a part of the metal is extruded from the overflow hole 17, and the overflow can be judged by observing the height of the metal extruded in the overflow hole 17 The pre-tightening force of the bolts 13 at the corresponding positions of the holes 17, so that when the pipeline body 1 is installed in the field, a simple wrench can be used to ensure that the pre-tightening force of the bolts 13 connected between the left flange 11 and the right flange 12 is uniform , reduce the cost of using a torque wrench, avoid local st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com