Drawing frame and compaction device for spinning machine

A drafting device and compressing device technology, which is applied to spinning machines, drafting equipment, textiles and papermaking, etc., can solve the problem of not being able to ensure that the hollow part is pressed against the roller, and achieve the effect of reliable and uniform compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

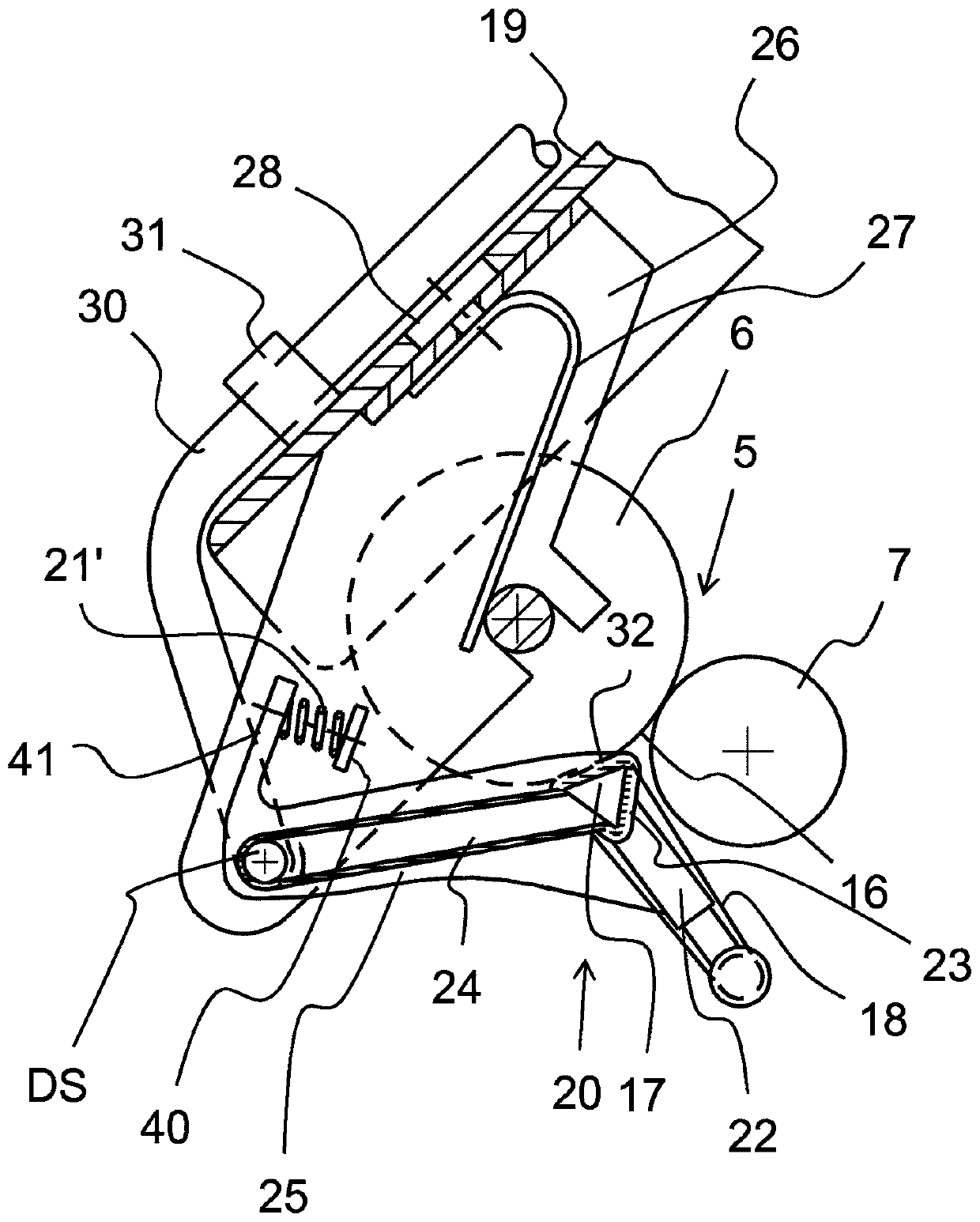

[0034] In the following description of the alternative embodiments, the same reference numerals are used for identical and / or at least similar features of technical solution and / or operating principle. If these features are not described in detail again, their technical solutions and / or working principles are equivalent to those of the previously described features.

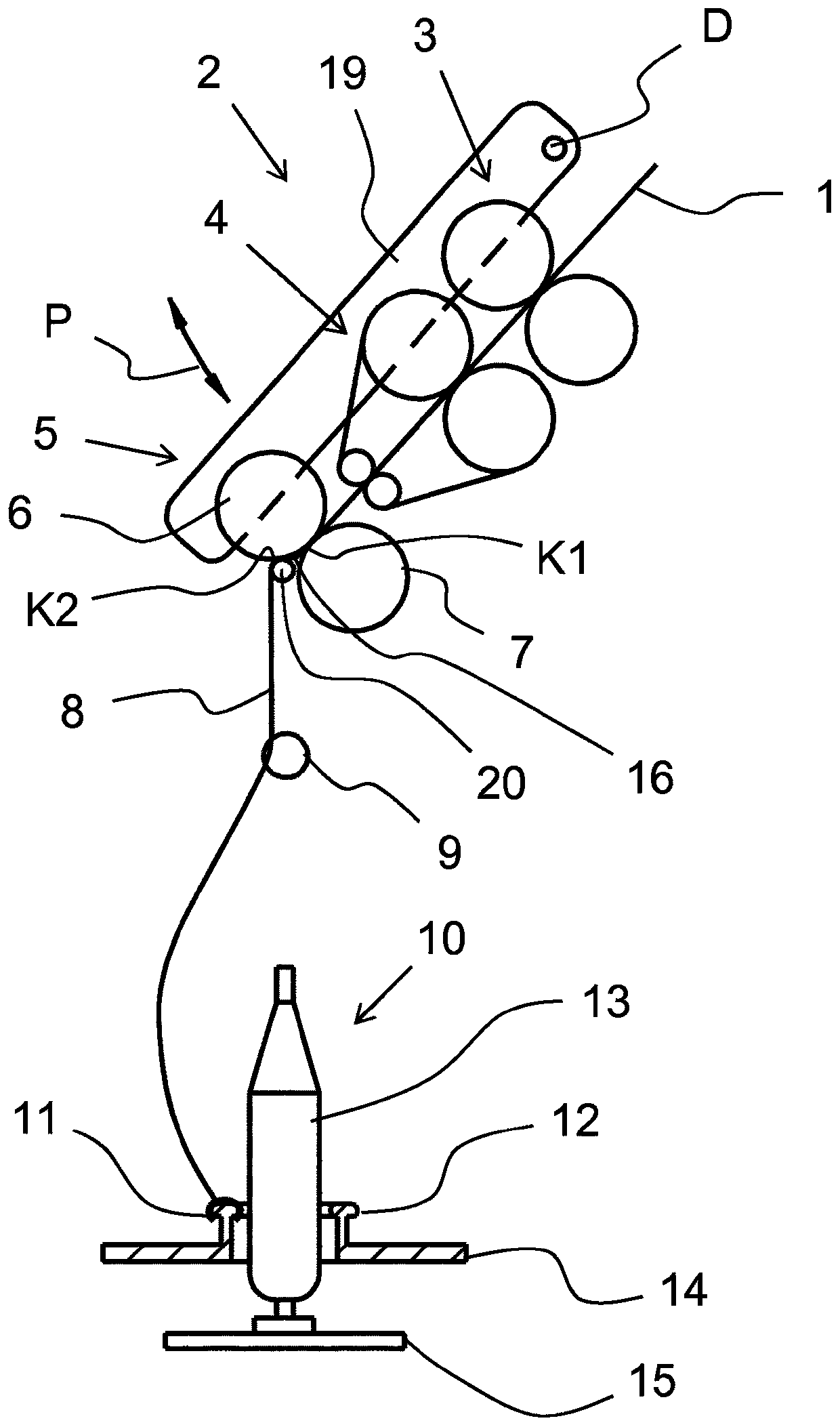

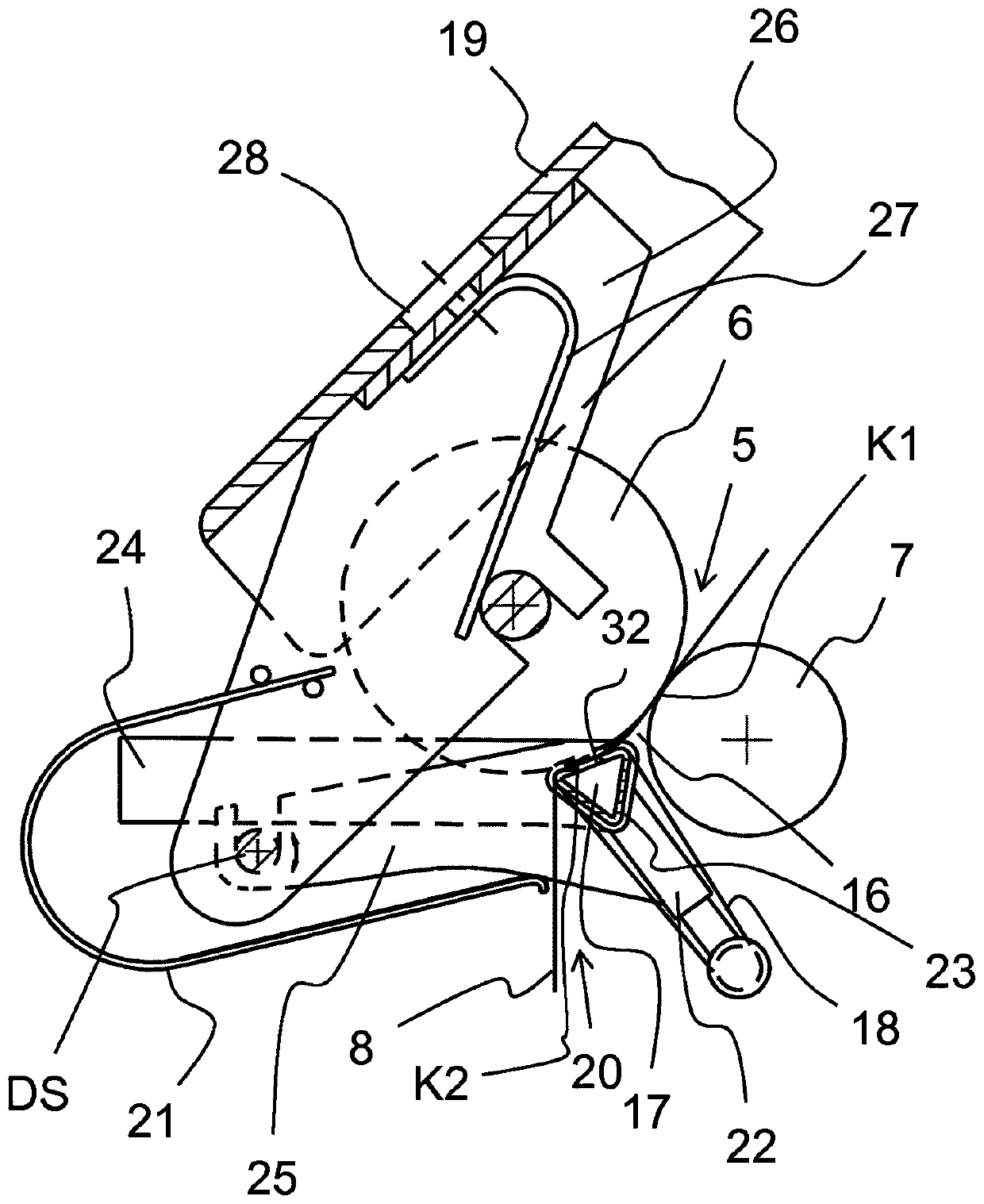

[0035] figure 1 is a schematic illustration of a longitudinal section of a spinning machine, in particular a ring spinning machine with a compression device 20 . Several components of the spinning machine, namely the drafting device 2 and the spinning device 10 are schematically shown in the figure. The drafting device 2 is composed of three roller pairs: an input roller pair 3 , a belt roller pair 4 and an output roller pair 5 . The output roller pair 5 is formed by the output top roller 6 and the output bottom roller 7 . The two rollers of a roller pair come together and form a clamping point at their point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com