Passive sensor device for measuring shock wave energy based on combined aluminum honeycomb

A sensor device and passive measurement technology, which is applied in the field of measurement and detection, can solve problems such as cumbersome processing procedures, complex measurement systems, and difficult wiring, and achieve the effects of simple and intuitive results, high response sensitivity, and convenient layout and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate those of ordinary skill in the art to understand and implement the patent of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

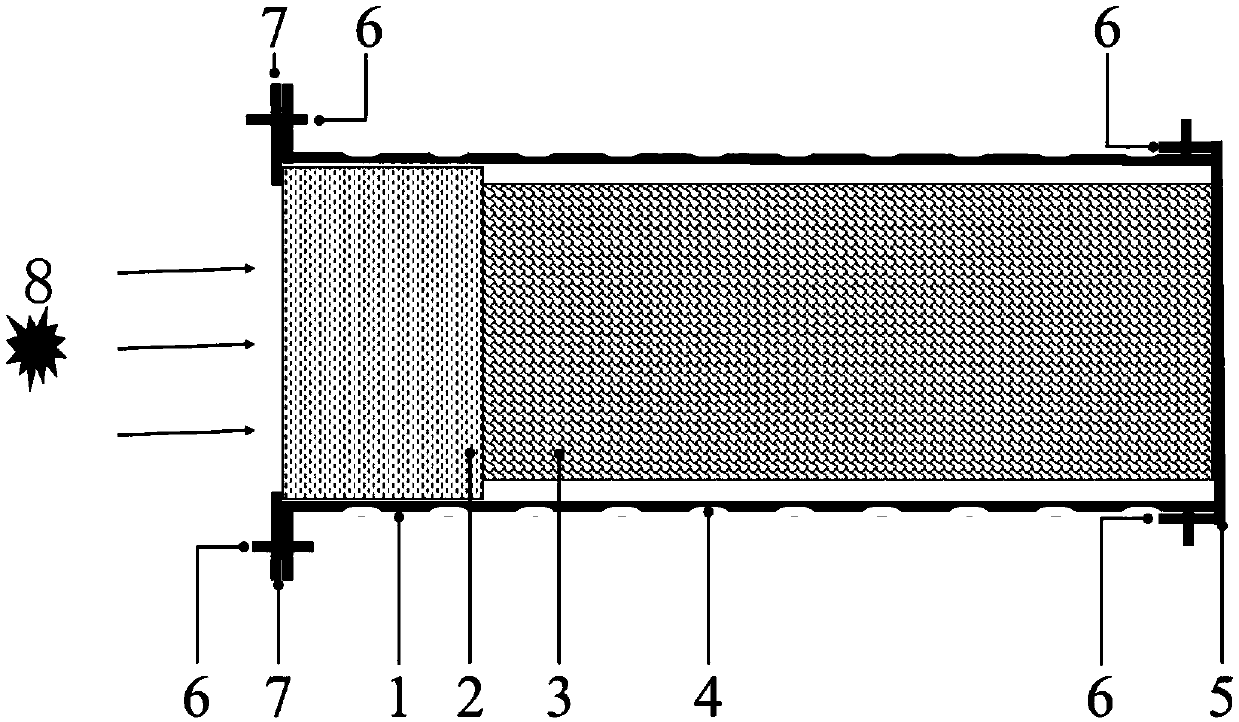

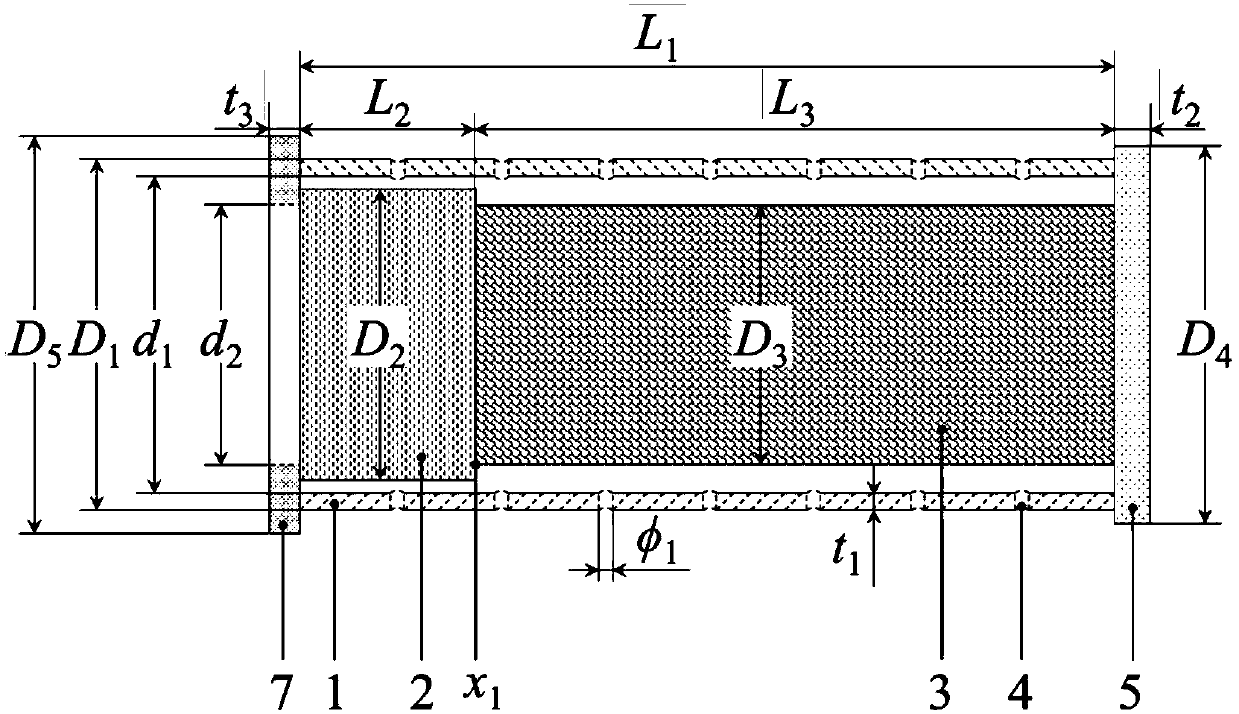

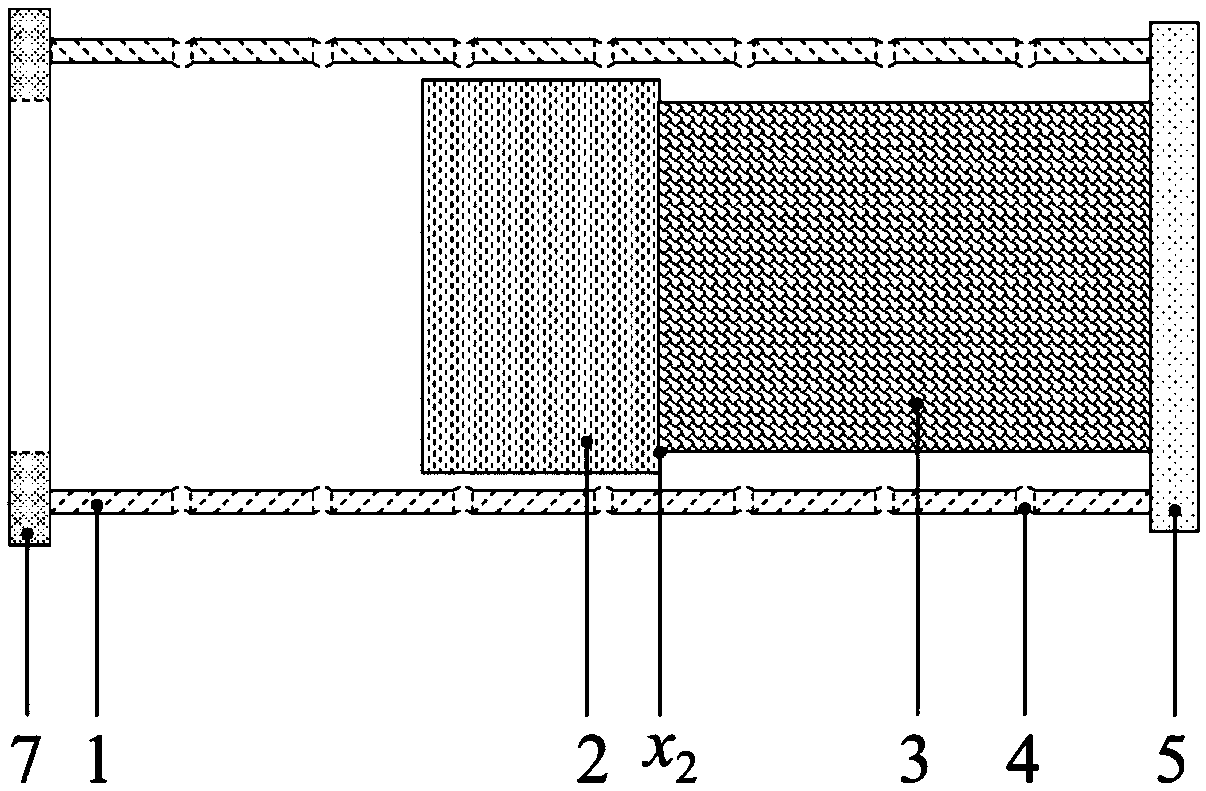

[0034] figure 1 It is a schematic diagram of the overall structure of the sensor for passively measuring shock wave energy provided by the present invention. Such as figure 1 shown.

[0035] The present invention is composed of a packaging case 1, a driving slider 2, a combined aluminum honeycomb energy-absorbing component 3, a solid wall stop plate 5, a movable bolt 6, and a sealing retaining ring 7. The end of the present invention close to the explosion point 8 is the left end of the present invention, and the end of the present invention far away from the explosion point 8 is the right end. The driving slider 2 and the combined aluminum honeycomb energy-absorbing member 3 are located in the packaging casing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com