Planet rotating device and coating equipment capable of achieving large-batch production

A rotating device and planetary technology, applied in sputtering plating, ion implantation plating, gaseous chemical plating, etc., can solve the problems of deviation of film thickness uniformity, low coating efficiency, poor uniformity, etc., to facilitate later maintenance, Improve coating efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

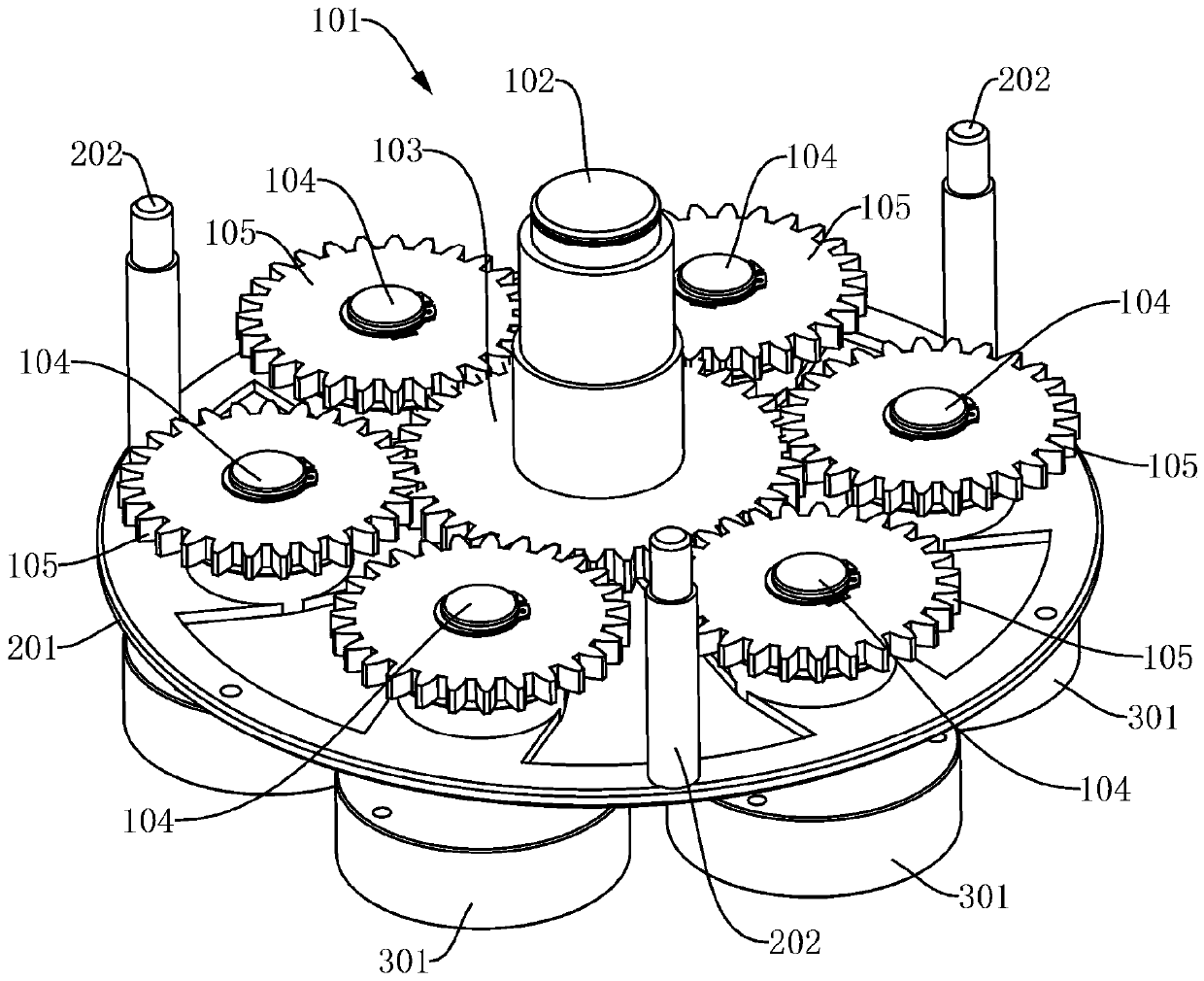

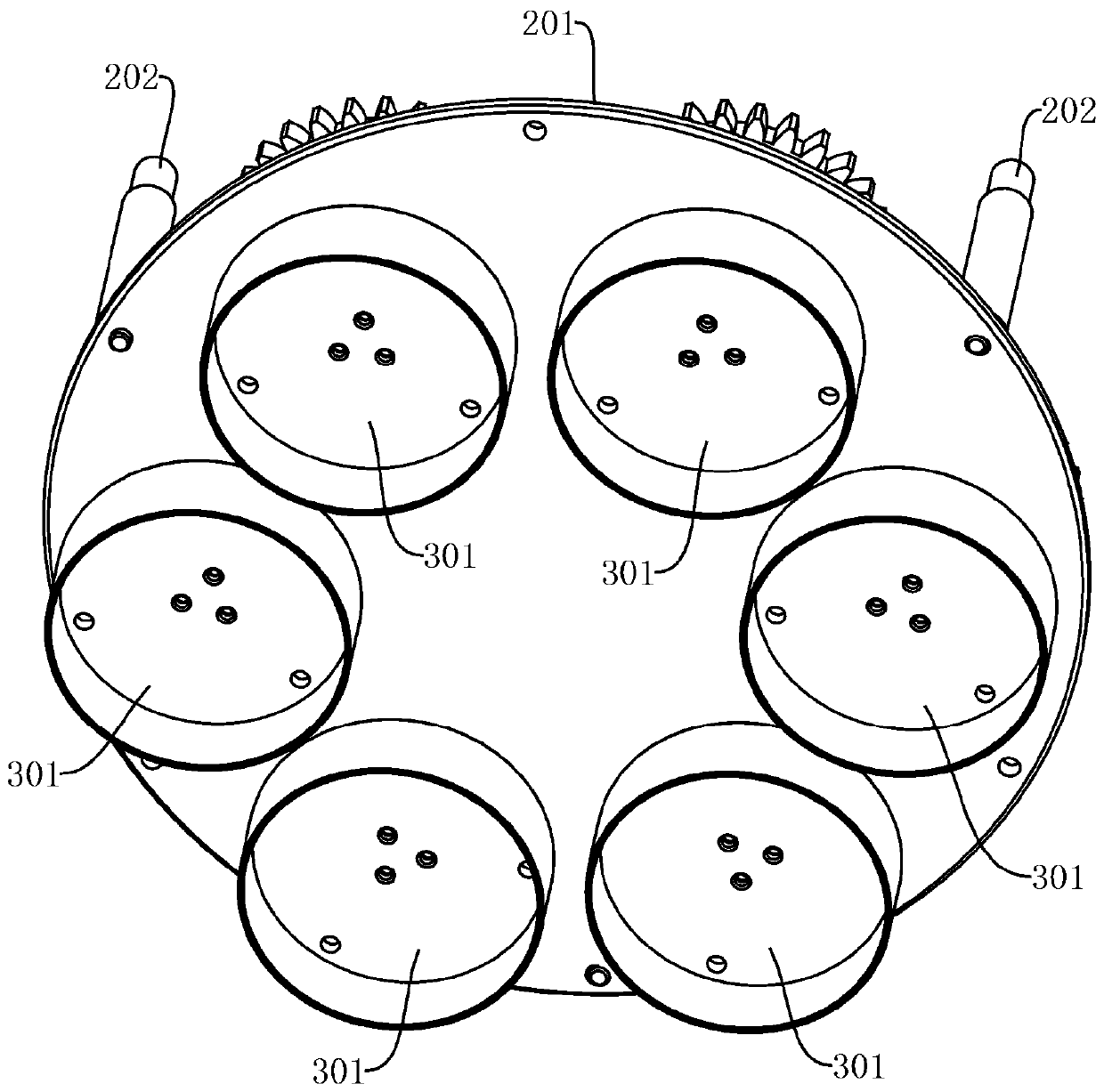

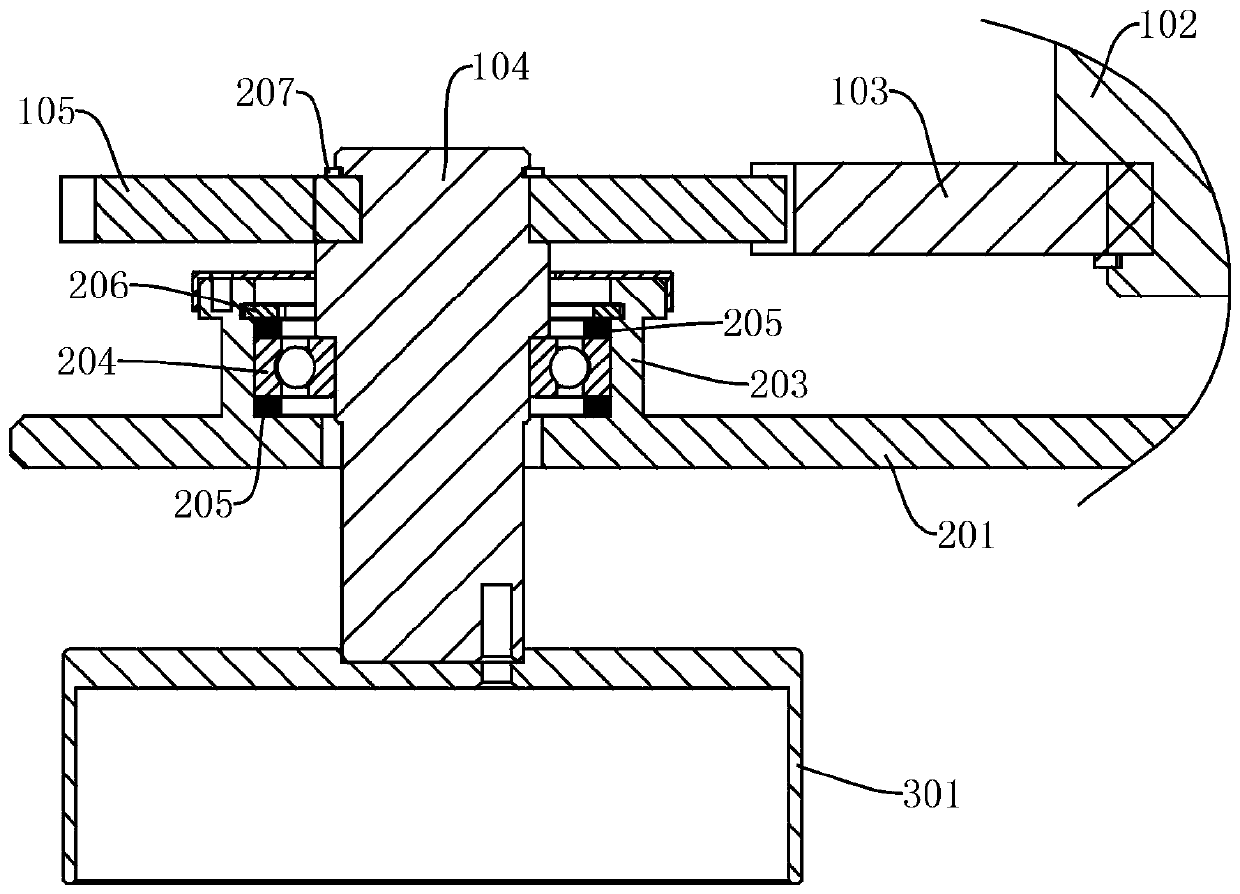

[0044] see figure 1 , figure 2 , the present embodiment provides a planetary rotation device that can enhance the uniformity of the surface film thickness of the spherical element, including a plurality of workpiece suspension plates 301 and the first transmission mechanism 101, and each workpiece suspension plate 301 is connected to the first transmission mechanism respectively. 101 connected, the first transmission mechanism 101 is used to drive the synchronous rotation of each workpiece suspension pan 301; in this planetary rotation device, the number of workpiece suspension pans 301 can be determined according to actual needs, and in actual assembly, the first transmission mechanism 101 is directly or indirectly fixed on the planetary turntable 401 in the existing coating equipment, and the first transmission mechanism 101 is driven to revolve by the planetary turntable 401, and the first transmission mechanism 101 is provided with several workpiece hanging plates 301, ea...

Embodiment 2

[0055] The main difference between this embodiment 2 and the above-mentioned embodiment 1 is that the planetary rotation device provided by this embodiment also includes a second transmission mechanism and a third transmission mechanism 601, and the second transmission mechanism includes a planetary turntable 401 and a gear transmission mechanism; The planetary turntable 401 of the second transmission mechanism rotates under the drive of the motor through the third transmission mechanism 601; the second transmission mechanism is respectively connected with the first transmission mechanism 101 described in Embodiment 1, and the second transmission mechanism is connected through the main transmission The shaft 102 drives the first transmission mechanisms 101 to rotate and / or revolve synchronously; not only can the workpiece suspension plates 301 in the planetary rotating device rotate and revolve, which is beneficial to improve the uniformity of the film layer, but also greatly in...

Embodiment 3

[0062] This embodiment provides a coating device capable of mass production, including the planetary rotation device described in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com