Technologic process and special apparatus for rolling seamless steel pipe

A seamless steel pipe and process technology, applied in the field of seamless steel pipe rolling, can solve the problems of narrow specification range and can only meet small batch production, and achieve the effect of highlighting substantive characteristics and expanding the range of product specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

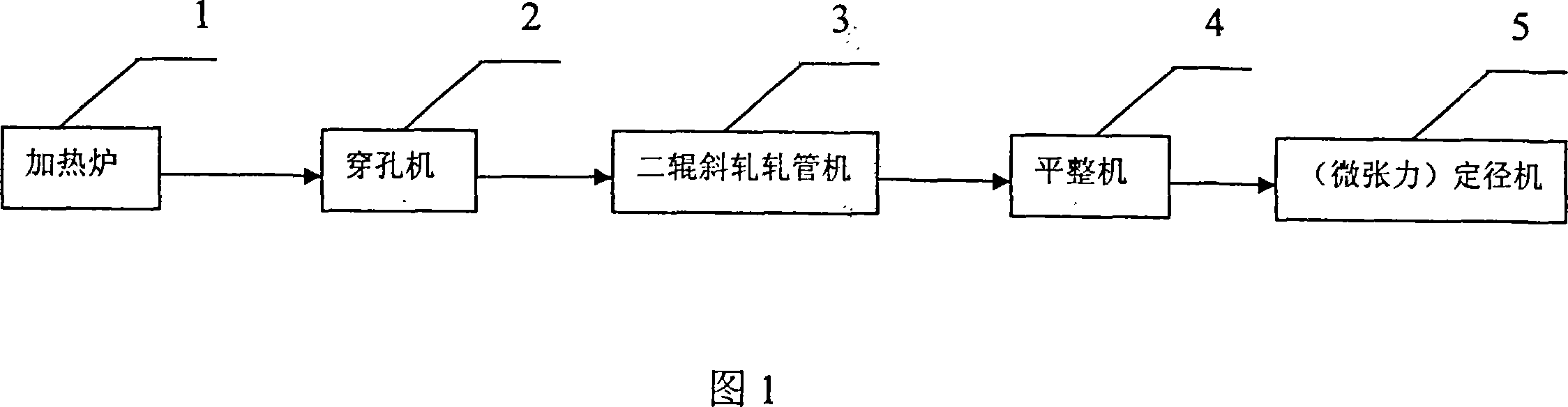

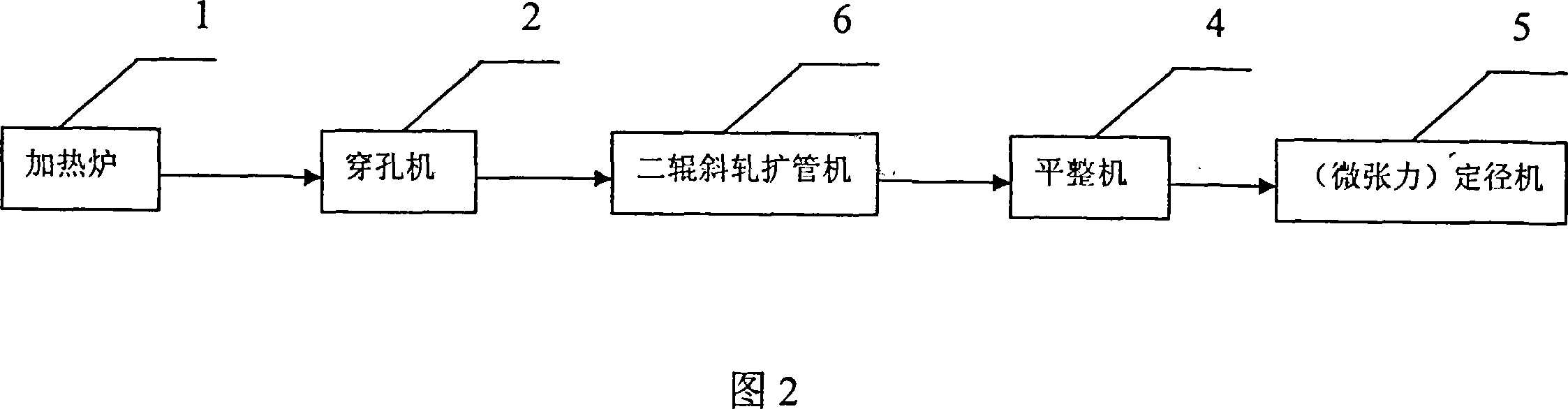

[0021] Embodiment 1, with reference to Figures 1, 2, and 3, the tube blank is heated to the required temperature by the tube blank heating furnace 1, and then the solid tube blank is pierced into a hollow capillary tube by the piercer 2, and the tube is expanded by two-roll cross rolling The machine 6 reduces the capillary wall and expands the diameter, and the diameter of the steel pipe can be enlarged by 15 to 60% according to the needs, and then the steel pipe is leveled by the leveling machine 4 to further improve the inner and outer surface quality and wall thickness accuracy of the steel pipe, and then the micro tension sizing machine 5. Round the steel pipe to obtain the seamless steel pipe with the required diameter.

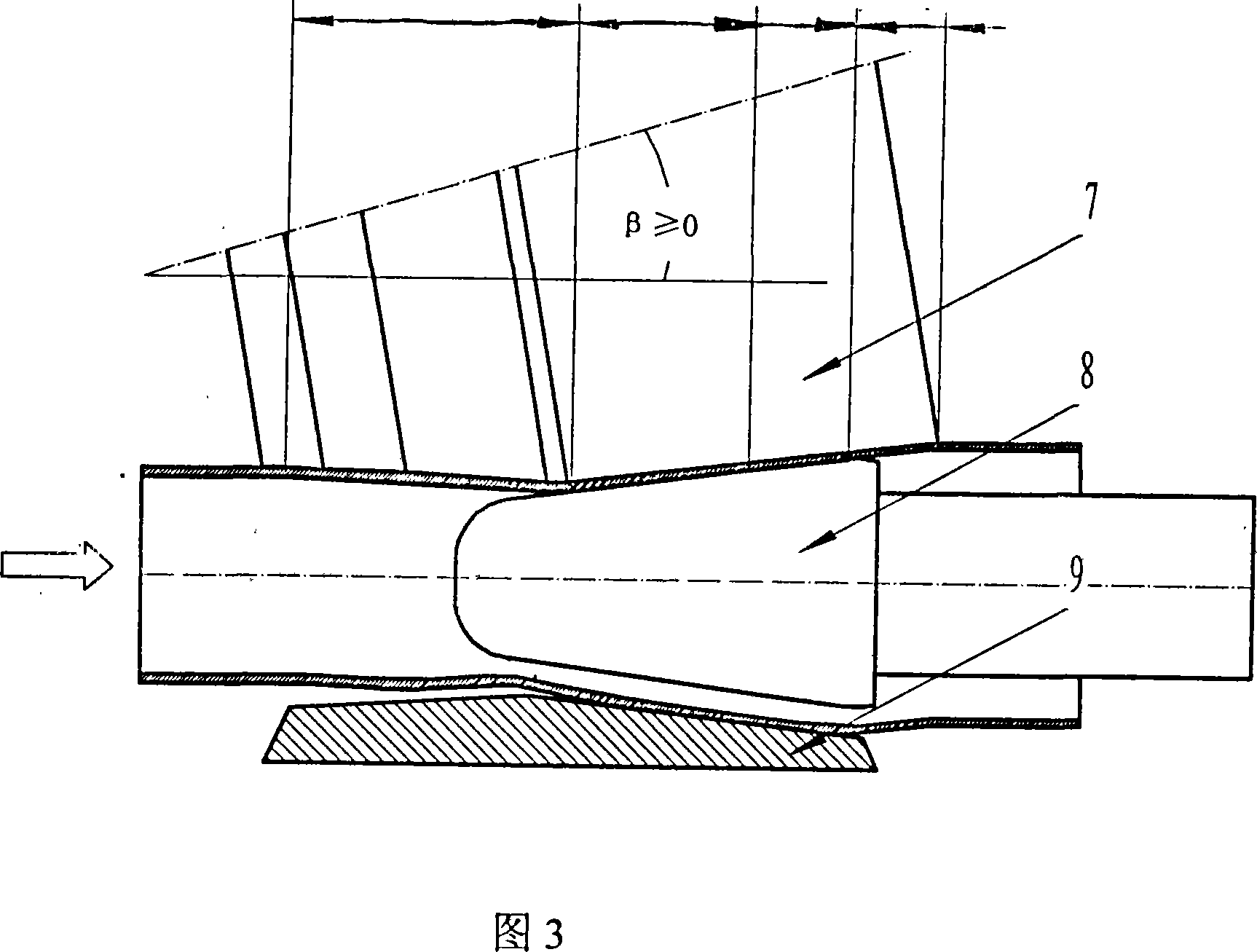

[0022] The above-mentioned two-roll cross rolling pipe expander 6 is composed of two rolls 7, a plug 8 and two guide plates 9, two guide plates 9 are installed between the two rolls 7, and the plug 8 is installed in the center of the two guide plates 9; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com