Bumper device integrally formed by metal/composite material

A technology of composite materials and reinforced composite materials, which is applied in the field of automobile lightweight and collision safety, can solve the problems of inapplicability, limited raw materials, high cost, etc., and achieve the effect of light weight, good recyclability, and small quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

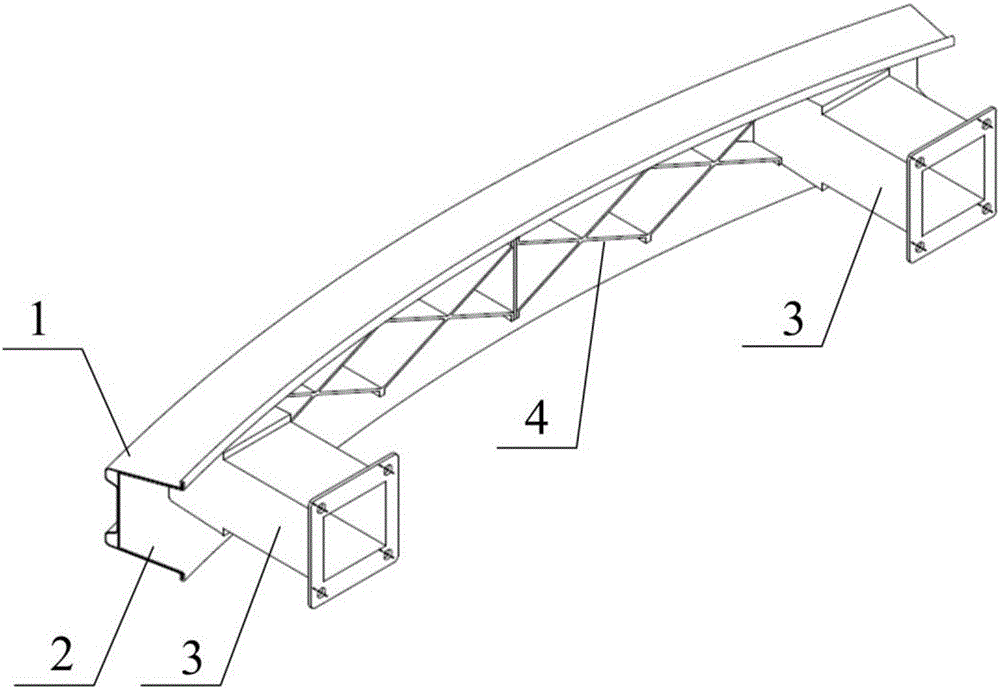

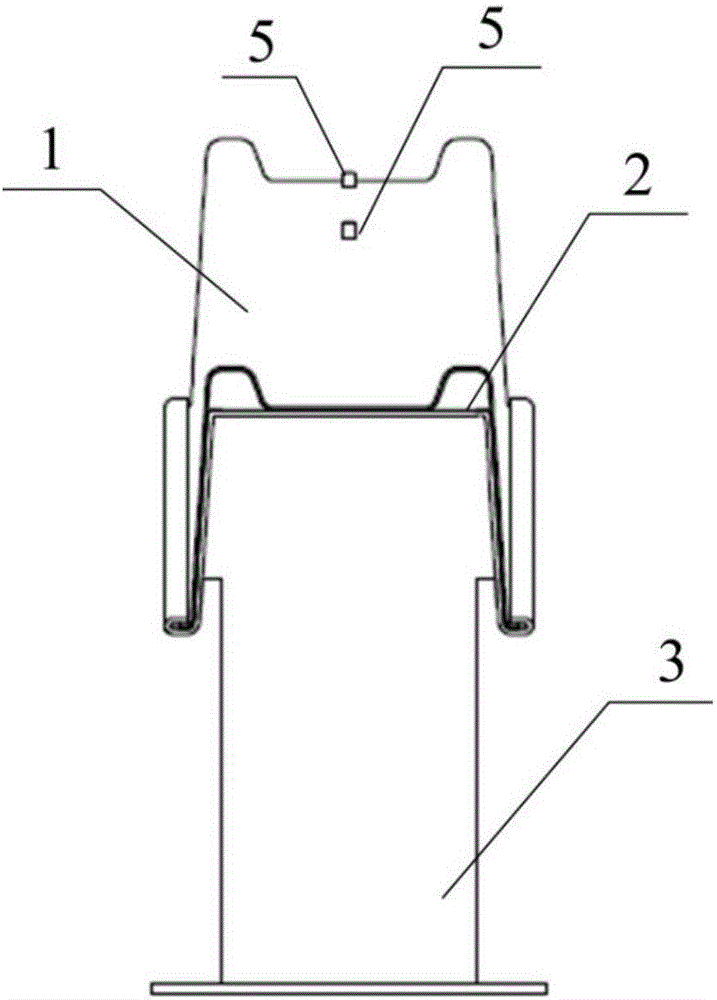

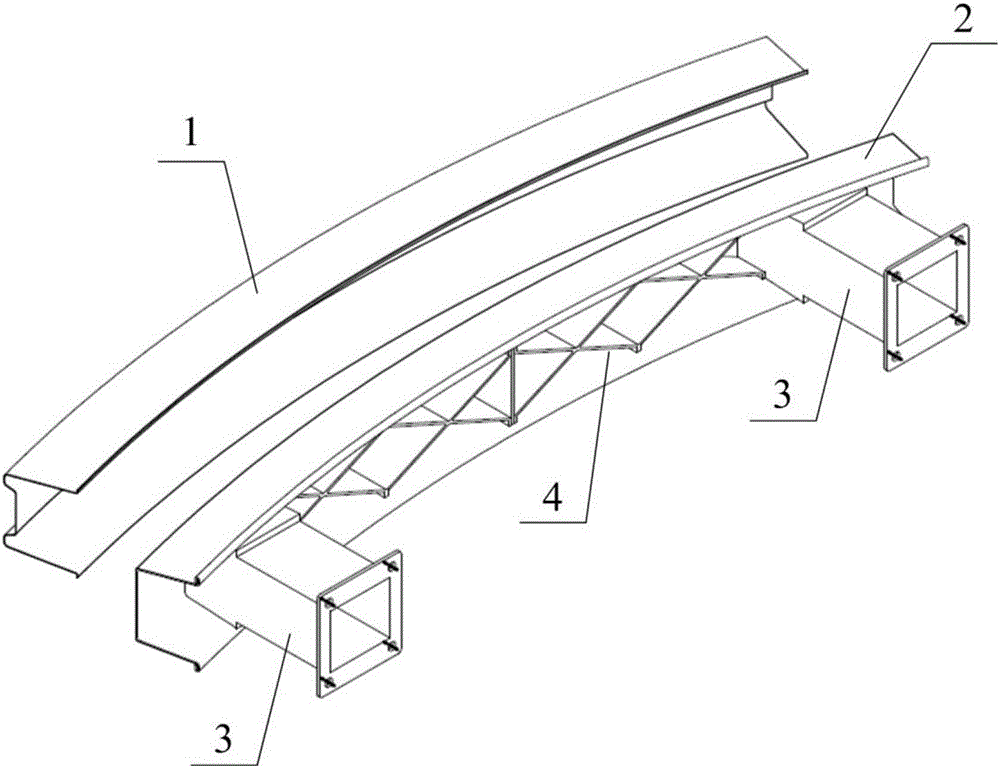

[0023] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in further detail:

[0024] As shown in the drawings, the present invention is a metal / composite material integrated bumper device, including the following parts: bumper beam metal outer panel 1, bumper beam composite material inner panel 2, energy absorbing box 3, composite material Inner panel stiffener 4, composite material lock 5. The position connection relationship between them is: the metal outer panel 1 of the bumper beam and the inner panel 2 of the composite material of the bumper beam are adhered together through injection molding; the inner panel 2 of the composite material of the bumper beam is fixedly connected with the energy-absorbing box 3 , which is integrated injection molding; the energy-absorbing box 3 is located at both ends of the inner panel 2 of the bumper beam composite material; the reinforcing rib 4 of the inner panel of the composite material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com