Method of extracting decapterus maruadsi oil through low-temperature continuous phase transition

A low-temperature continuous phase change, blue round trevally technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problem that the research on blue round trevally oil components has not been reported, and achieves reduction of the loss of low-boiling point components, convenient operation, batch processing, etc. High-volume effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The present embodiment provides the preparation of blue round trevally oil, and the preparation method comprises the following steps:

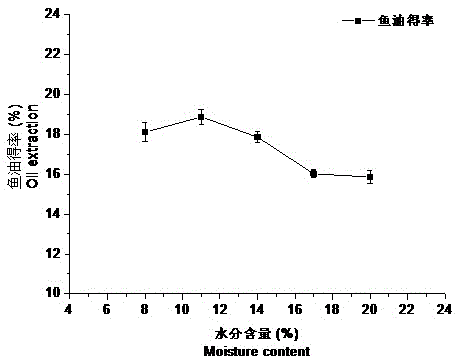

[0047] S1. Wash the fresh blue squid, dry other tissue parts except the viscera at 56°C, take out the viscera and use vacuum freeze-drying, crush to make the water content of 10-13%, and obtain the powdery raw material of blue squid;

[0048] The vacuum freeze-drying can refer to the prior art. Preferably, the vacuum freeze-drying conditions adopted in this embodiment are heating plate temperature 45°C, material thickness 5mm, drying chamber pressure 50pa, and pre-freezing temperature -20°C.

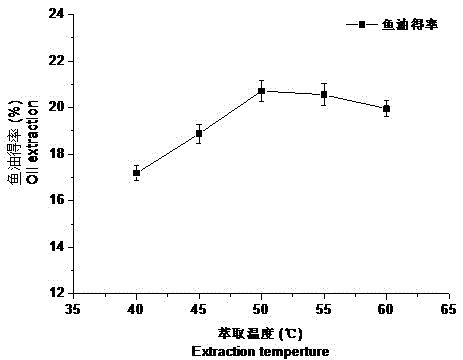

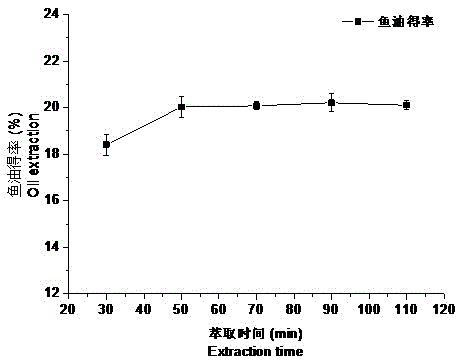

[0049] S2. Weigh 300g of the processed blue scad powder raw material, put it into the extraction kettle of the continuous phase change extraction device, and flow it at a flow rate of 120L / h under the conditions of extraction temperature 50°C and extraction pressure 0.6Mpa Continuously extract for 50 minutes through the extraction tank, after ext...

Embodiment 2

[0052] The present embodiment provides the preparation method of blue round trevally oil, comprises the following steps:

[0053] S1. Wash the fresh blue carp, dry other tissue parts except the internal organs at a temperature of 52° C., take out the viscera and use vacuum freeze-drying, crush to make the water content 10-13%, and obtain the powdery raw material of blue carp; Vacuum freeze-drying can refer to prior art. Preferably, the vacuum freeze-drying conditions adopted in this embodiment are heating plate temperature of about 48°C, material thickness of 6mm, drying chamber pressure of 55pa, and pre-freezing temperature of -18°C.

[0054] S2. Weigh 300g of the treated trevally powder raw material, put it into the extraction kettle of the continuous phase change extraction device, and flow through the extraction at a flow rate of 110L / h under the conditions of extraction temperature 45°C and extraction pressure 0.5Mpa Kettle, continuous extraction for 70min. After extract...

Embodiment 3

[0057] The present embodiment provides the preparation method of blue round trevally oil, comprises the following steps:

[0058] S1. Wash the fresh blue carp, dry other tissue parts except the viscera at 48°C, take out the viscera, use vacuum freeze-drying, crush to make the water content 10-13%, and obtain the blue carcass powder raw material; Vacuum freeze-drying can refer to prior art. Preferably, the vacuum freeze-drying conditions adopted in this embodiment are heating plate temperature 40°C, material thickness 4mm, drying chamber pressure 50pa, and pre-freezing temperature -20°C.

[0059] S2. Weigh 300g of the treated trevally powder raw material, put it into the extraction kettle of the continuous phase change extraction device, and flow through the extraction at a flow rate of 100L / h under the conditions of extraction temperature 60°C and extraction pressure 0.3Mpa Kettle, continuous extraction for 110min, after the fish oil is extracted, it flows into the analysis k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com