Method for white copper-tin electroplating on permanent magnetic material

A technology of permanent magnet material and cupronickel, which is applied in the field of anticorrosion of permanent magnet material, to achieve the effect of saving electroplating cost and good anticorrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] First put 2.5kg The sintered NdFeB permanent magnet material was mechanically vibrated in a vibration mill for 2 hours, then degreased and degreased with an alkaline solution (sodium phosphate 20g / L, sodium carbonate 10g / L and sodium hydroxide 10g / L), and then in Pickling in 1% nitric acid solution, electroplating nickel, see (CN200910244404) for details, using Watt nickel formula nickel sulfate 220 g / l, nickel chloride 40 g / l, boric acid 40 g / l, pH 4.8 temperature 42°C. The thickness of the nickel layer is 5 microns, and electroplating copper is carried out after washing with water. The formulation of the electroplating solution is as follows: copper pyrophosphate 60 g / L, potassium pyrophosphate 300 g / L, pH 8.2, temperature 50°C, and the thickness of the electroplated copper layer is 7 microns. Electroplated copper-tin alloy after water washing. Copper-tin alloy plating solution includes Cu 2 P 2 o 7 ·3H 2 O16g / L, Sn 2 P 2 o 7 12g / L, K 4 P 2 o 7 ·3H 2 O20...

Embodiment 2

[0021] According to the method of embodiment 1 to 2.5kg The NdFeB permanent magnet material is subjected to surface pretreatment, and the surface of the permanent magnet material is nickel-plated and then copper-plated, and copper-tin alloy is electroplated after washing with water. Electroplated copper-tin alloy after water washing. Copper-tin alloy plating solution includes Cu 2 P 2 o 7 ·3H 2 O19g / L, Sn 2 P 2 o 7 15g / L, K 4 P 2 o 7 ·3H 2 O250g / L, K 2 HPO 4 80g / L, complexing agent FCS-A120ml / L, stabilizer FCS-B30ml / L, brightener FCS-C20ml / L (complexing agent FCS-A, stabilizer FCS-B and brightener FCS-C are all purchased from obtained from Guangzhou Medis). The electroplating temperature is 25° C., the pH is 8.5, and the thickness of the Cu—Sn alloy plating layer is 20 μm.

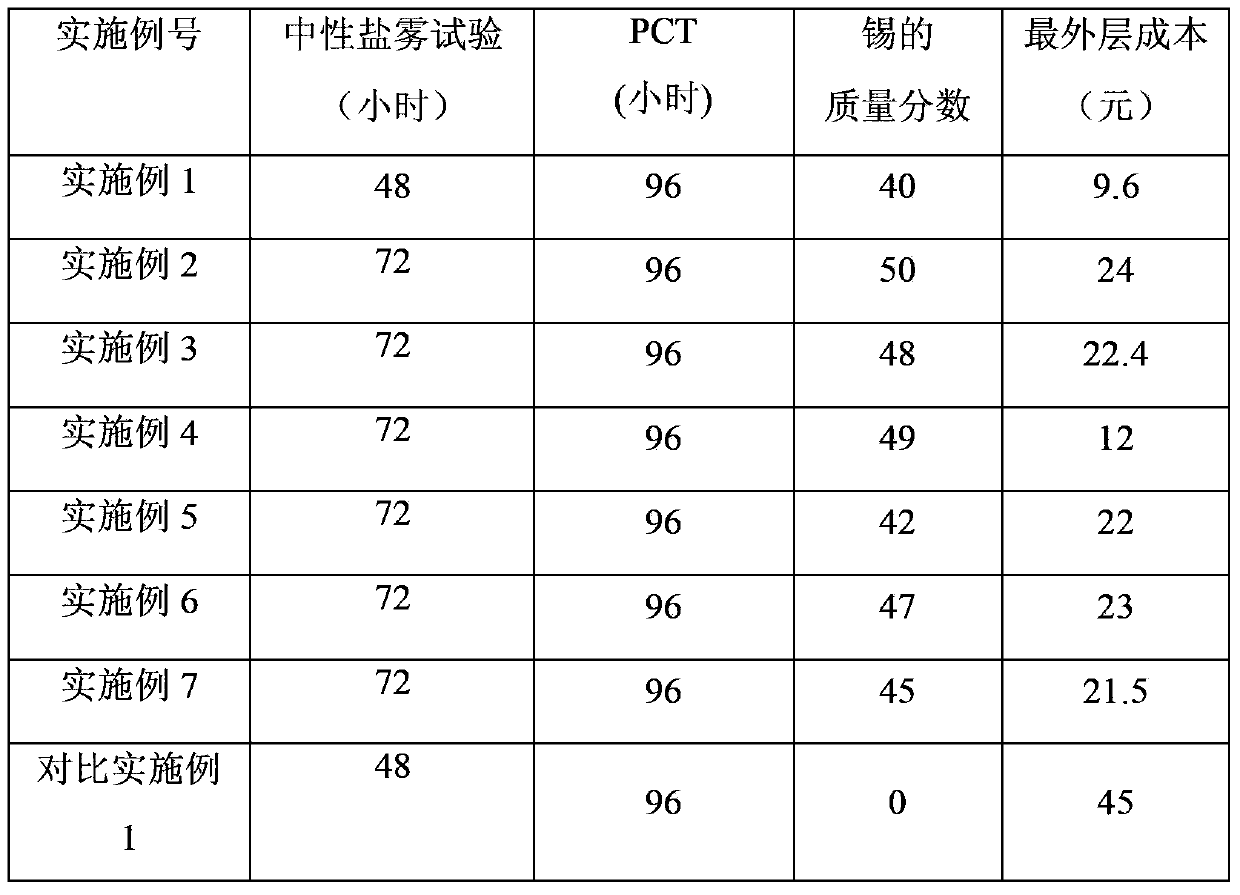

[0022] It can be seen from the neutral salt spray test that the NdFeB permanent magnet obtained by the surface protection method of the NdFeB permanent magnet of the present invention has a...

Embodiment 3

[0024] According to the method of embodiment 1 to 2.5kg The NdFeB permanent magnet material is subjected to surface pretreatment, and the surface of the permanent magnet material is nickel-plated and then copper-plated, and copper-tin alloy is electroplated after washing with water. Electroplated copper-tin alloy after water washing. Copper-tin alloy plating solution includes Cu 2 P 2 o 7 ·3H 2 O17g / L, Sn 2 P 2 o 7 14g / L, K 4 P 2 o 7 ·3H 2 O220g / L, K 2 HPO 4 70g / L, complexing agent FCS-A100ml / L, stabilizer FCS-B20ml / L, brightener FCS-C16ml / L (complexing agent FCS-A, stabilizer FCS-B and brightener FCS-C are all purchased from obtained from Guangzhou Medis). The temperature of the electroplating is 22° C., the pH is 8.6, and the thickness of the Cu—Sn alloy plating layer is 12 μm.

[0025] It can be seen from the neutral salt spray test that the NdFeB permanent magnet obtained by the surface protection method of the NdFeB permanent magnet of the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com