Preparation method of copper-tin alloy with high tin content and high density

A copper-tin alloy, high-density technology, applied in the field of powder metallurgy, can solve the problem of low hardness of copper-tin alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

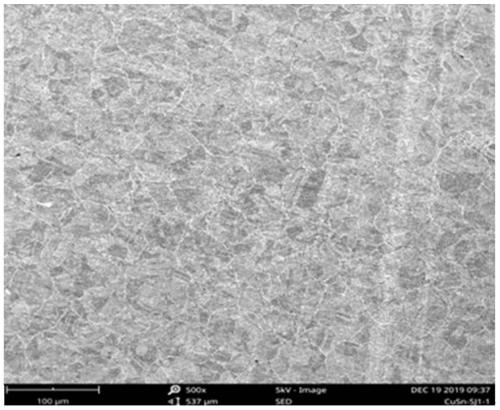

Image

Examples

preparation example Construction

[0022] A preparation method of a high-tin content high-density copper-tin alloy, specifically carried out according to the following steps:

[0023] Step 1: Weigh 83.2-84.3wt.% of Cu powder, 15.4-16.5% of Sn powder, and 0.3% of Ti powder according to mass percentage, and use a ball mill to mix the components evenly to obtain a mixed powder;

[0024] Step 2: cold pressing the mixed powder in step 1 to obtain a cold compact, and placing the cold compact in an atomization deposition furnace for atomization deposition to obtain a pre-alloyed powder;

[0025] Step 3: Sieve the pre-alloyed powder in step 2 to obtain a powder, add alcohol and stir the powder and perform secondary cold pressing to obtain a secondary cold compact, and put the secondary cold compact into an atmosphere sintering furnace In the middle, pass inert gas, heat up the atmosphere sintering furnace to 540-570°C and start to pressurize the cold compact, and keep the pressure when the temperature of the atmosphere...

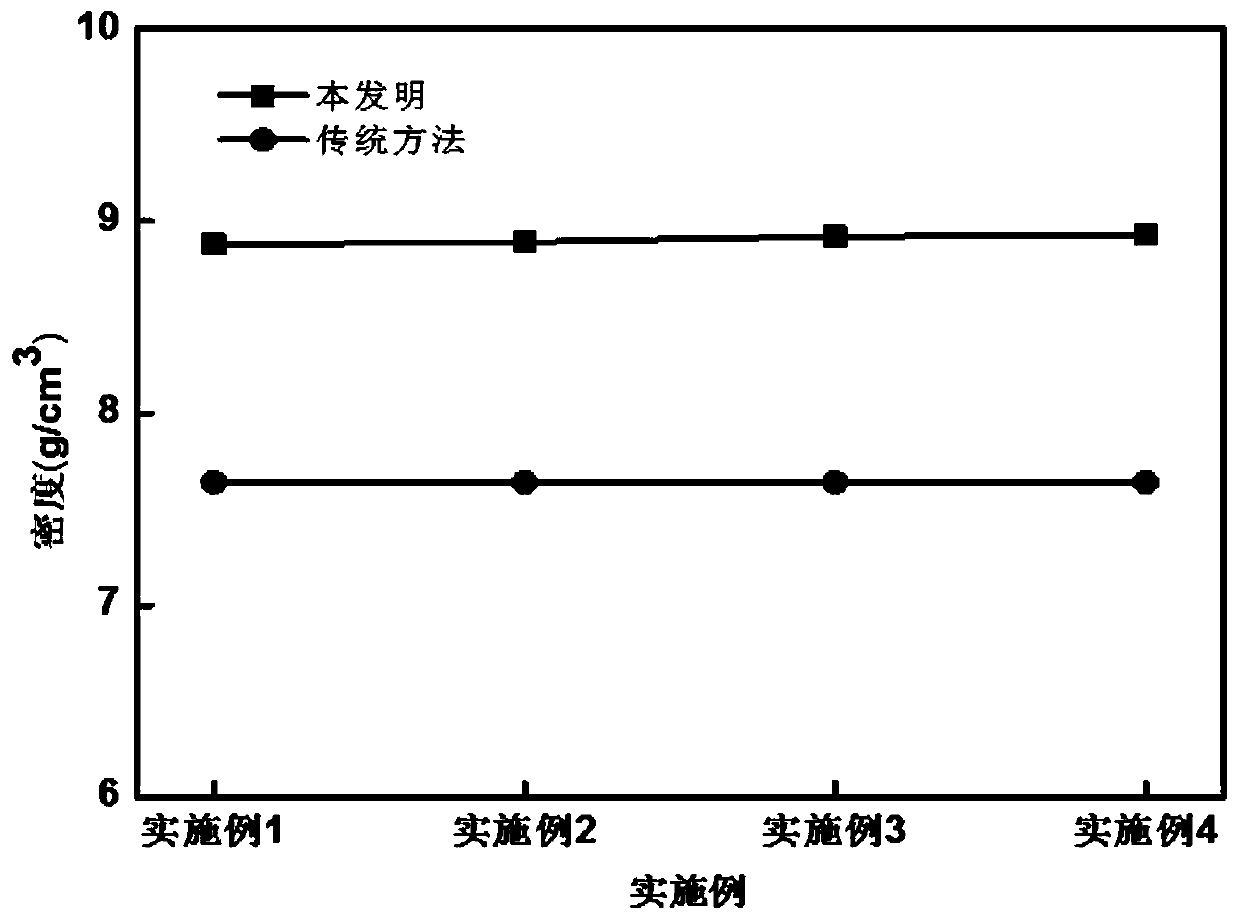

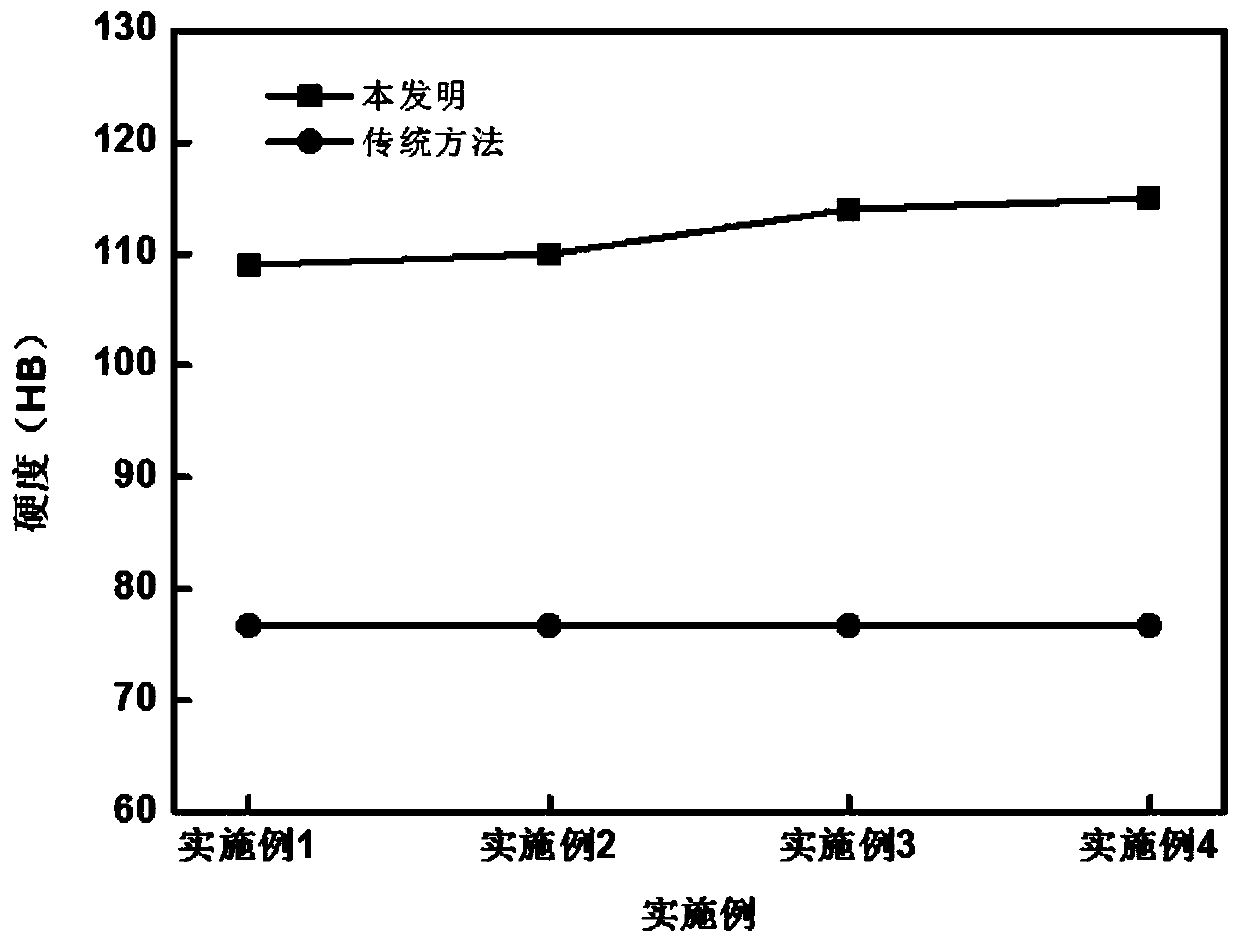

Embodiment 1

[0034] Weigh 83.7% of Cu powder, 16% of Sn powder, and 0.3% of Ti powder, and use a planetary ball mill to mix them evenly. Pour the powder into a pressing mold, and use a cold press to form a cold compact. Finally, put the cold-pressed embryo into the atomization deposition furnace, and vacuum the furnace body to 10 -3 After Pa, the argon gas of 0.01MPa is introduced, and then the furnace temperature is heated to 1200°C. When the cold compact is completely melted, the nitrogen valve is opened, the display is adjusted to 4.5MPa, and the nitrogen gas is continuously injected for atomization deposition. Pre-alloyed powder.

[0035] Sieve the obtained alloy powder, vibrate for 2 minutes, select a powder with a particle size of 75 μm, add an appropriate amount of alcohol to the powder, stir it evenly, pour it into a pressing mold, and press it on a cold press to form a cold compact.

[0036] Spread two layers of graphite paper on the bottom of the graphite crucible, put it into ...

Embodiment 2

[0038] Weigh 83.5% of Cu powder, 16.2% of Sn powder, and 0.3% of Ti powder, and use a planetary ball mill to mix them evenly. Pour the powder into a pressing mold, and use a cold press to form a cold compact. Finally, put the cold-pressed embryo into the atomization deposition furnace, and vacuum the furnace body to 10 -4 After Pa, argon gas of 0.02MPa was introduced, and then the furnace temperature was heated to 1280°C. When the cold compact was completely melted, the nitrogen valve was opened, and the reading was adjusted to 5.5MPa, and nitrogen gas was continuously injected for atomization deposition, and obtained Pre-alloyed powder.

[0039]Sieve the obtained alloy powder, vibrate for 2 minutes, select a powder with a particle size of 90 μm, add an appropriate amount of alcohol to the powder, stir it evenly, pour it into a pressing mold, and press it on a cold press to form a cold compact.

[0040] Spread two layers of graphite paper on the bottom of the graphite crucib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com