Powder metallurgy composite material with high compounding ratio and manufacturing method

A powder metallurgy and composite material technology, applied in the field of powder metallurgy, can solve the problem of poor bonding uniformity between powder matrix and solid lubricant, solve segregation and strength reduction, improve mechanical properties and wear resistance, and improve wear resistance. and strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

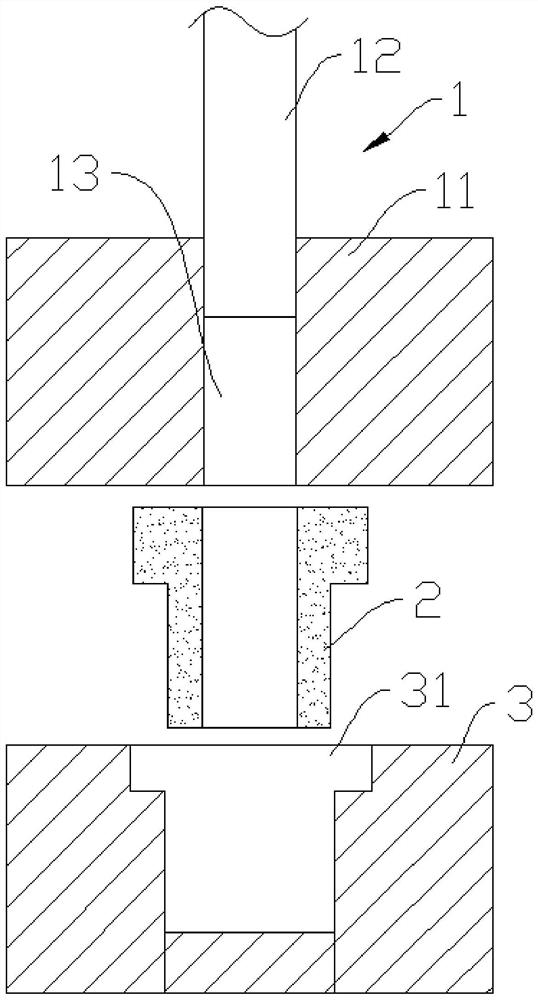

Image

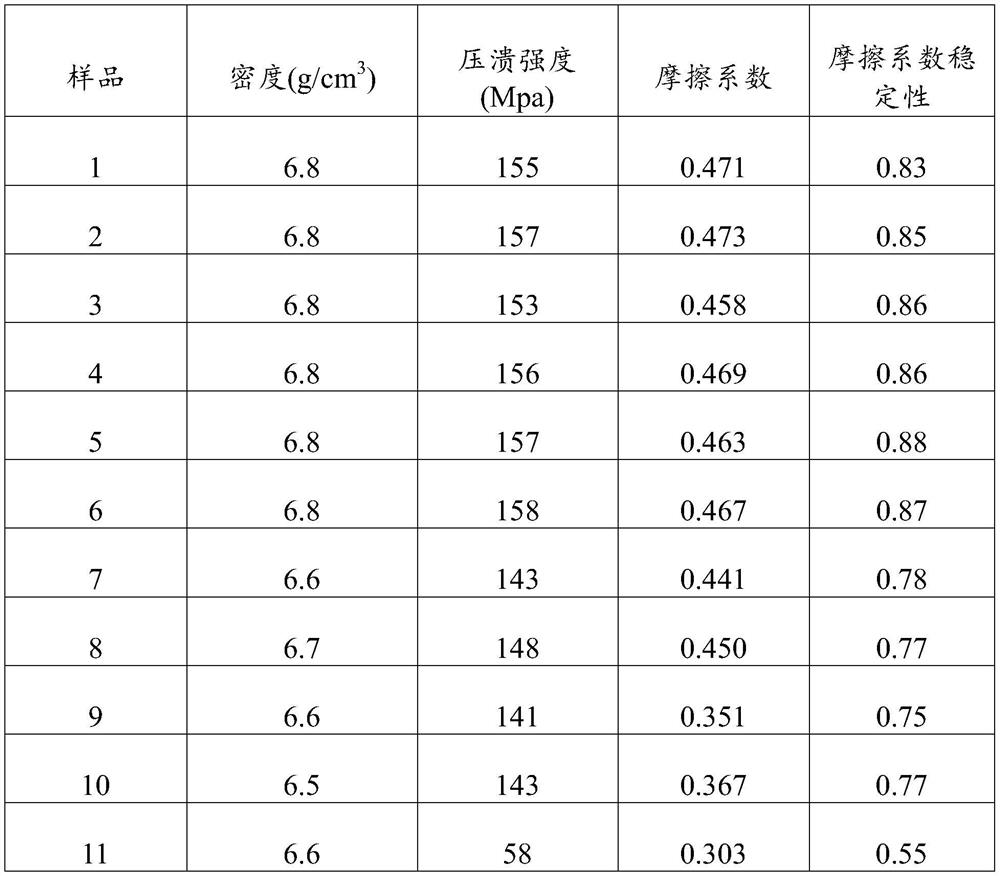

Examples

Embodiment 1

[0052] A powder metallurgy composite material with a high composite ratio, comprising the following components in parts by weight: 80 parts of copper-tin alloy powder with a particle size of -100 mesh, 5 parts of phosphor copper powder with a particle size of -400 mesh, and a particle size of -300 mesh 5 parts of micro-wax powder, 1 part of calcium carbonate powder with a particle size of -300 mesh, and 15 parts of nano-graphite carbon tubes.

[0053] A method for manufacturing a powder metallurgy composite material with a high composite ratio, comprising the following steps:

[0054] 1). Making the blank: taking by weighing each component except the nano-graphite carbon tube to prepare the mixture, and adding a forming lubricant, a pore-forming agent, a liquefying agent, and pressing the powder blank;

[0055] 2). Pre-burning-quenching: Under the protection of hydrogen, pre-fire at 450°C for 200 minutes, then in a continuous quenching furnace, under the protection of nitrogen...

Embodiment 2

[0061] A powder metallurgy composite material with a high composite ratio, comprising the following components in parts by weight: 95 parts of copper-tin alloy powder with a particle size of 150 mesh, 10 parts of phosphor copper powder with a particle size of -200 mesh, and micron powder with a particle size of -100 mesh 15 parts of wax powder, 10 parts of calcium carbonate powder with a particle size of -100 mesh, and 5 parts of nano graphite carbon tubes.

[0062] The manufacturing method of the powder metallurgy composite material with high compounding ratio, the steps are consistent with that of Example 1, and the obtained sample is recorded as Test Sample 2.

Embodiment 3

[0064] A powder metallurgy composite material with a high composite ratio, comprising the following components in parts by weight: 85 parts of copper-tin alloy powder with a particle size of -50 mesh, 8 parts of phosphor copper powder with a particle size of -300 mesh, and a particle size of -200 mesh 10 parts of micro-wax powder, 5 parts of calcium carbonate powder with a particle size of -200 mesh, and 6 parts of nano-graphite carbon tubes.

[0065] The manufacturing method of the powder metallurgy composite material with a high compounding ratio, the steps are the same as in Example 1, and the obtained sample is recorded as Test Sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com