Slotted wheel and manufacturing method thereof

A manufacturing method and technology of grooved wheels, which are applied in the direction of manufacturing tools, abrasives, metal processing equipment, etc., can solve the problems of short life, poor sharpness, poor heat resistance of grooved wheels, etc., and achieve long service life, high sharpness, cutting The effect of high ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below with reference to the accompanying drawings.

[0017] A grooved wheel, the material components of which include: copper-tin alloy powder, silver powder, polyimide resin powder, the components are: copper-tin alloy powder 70% to 95%; silver powder: 3 %~10%; polyimide resin powder: 1%~6%.

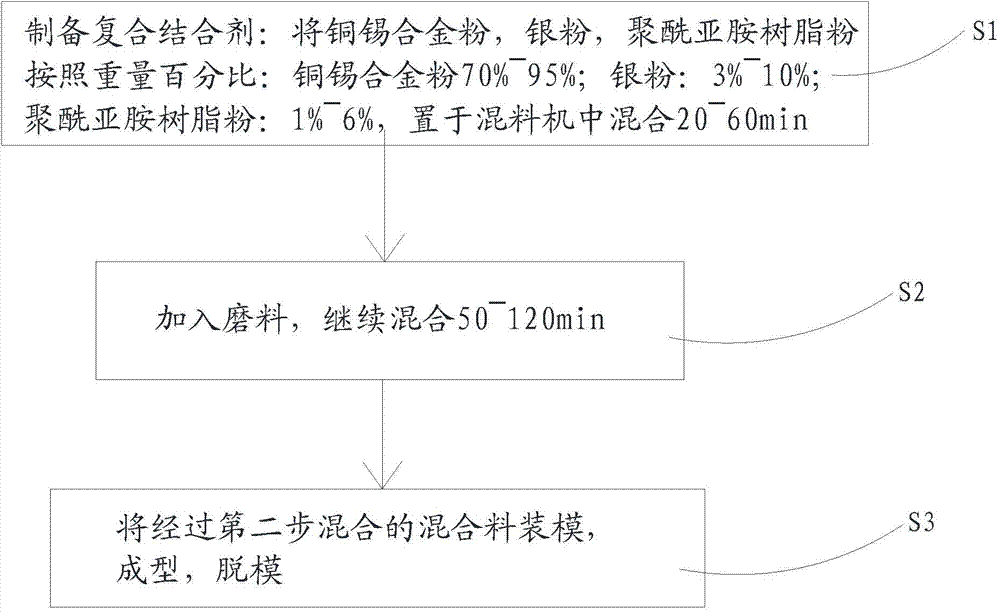

[0018] see figure 1 , a method of manufacturing a grooved wheel, comprising the following steps:

[0019] The first step S1 is to prepare a composite binder: mix copper-tin alloy powder, silver powder, and polyimide resin powder according to weight percentage: copper-tin alloy powder: 70%-95%; silver powder: 3%-10%; polyimide resin powder: 70%-95%; silver powder: 3%-10%; Resin powder: 1% to 6%, placed in a mixer and mixed for 20 to 60 minutes. Wherein, the mixer is a three-dimensional mixer.

[0020] In the second step S2, add abrasives and continue mixing for 50-120 minutes. Abrasives are steel balls to aid in mixing, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com