Method for simultaneously improving intensity, ductility and abrasion resistance of copper-tin alloys

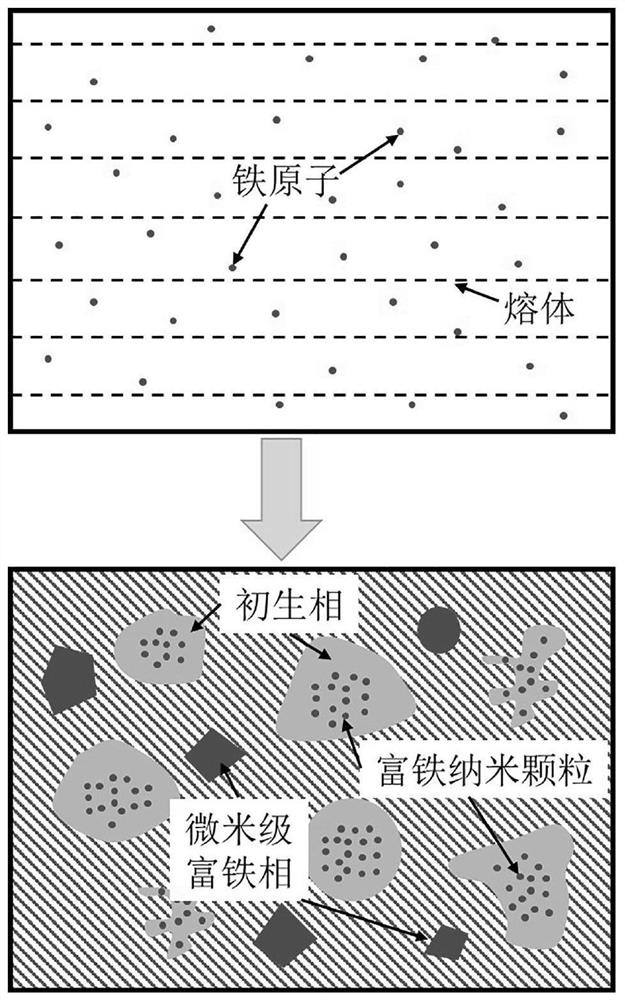

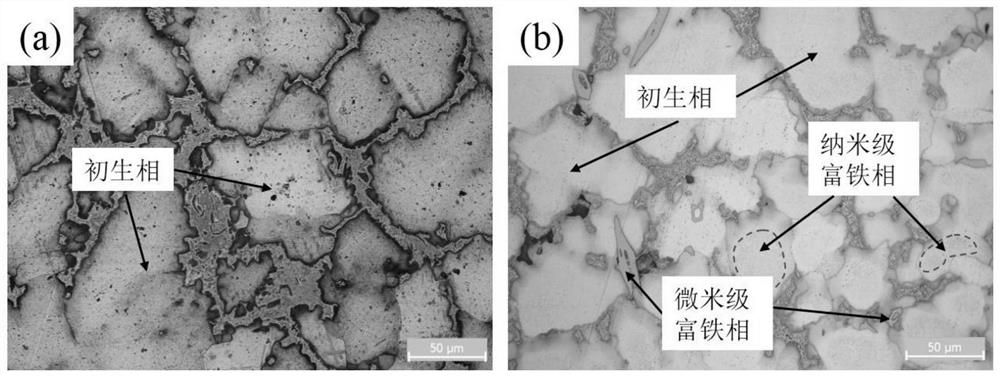

A technology of copper-tin alloy and wear resistance, which is applied in the field of material preparation, can solve the problems of surface fatigue failure of parts, parts are easy to break, and the service life is not high, so as to achieve fine microstructure, excellent casting performance and simple composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The material composition described in this embodiment is CuSn10Fe2P1 (wt.%), and the specific preparation method is as follows:

[0021] (1) Weigh about 5kg of pure copper, copper-tin master alloy, copper-iron master alloy, and copper-phosphorus master alloy, and use an intermediate frequency induction heating furnace to heat the alloy rapidly to 1350°C for 10min, then air-cool to 1080°C (liquidus line 1028 °C) for degassing and slag removal and standing for 3 minutes to homogenize the internal temperature field of the alloy melt.

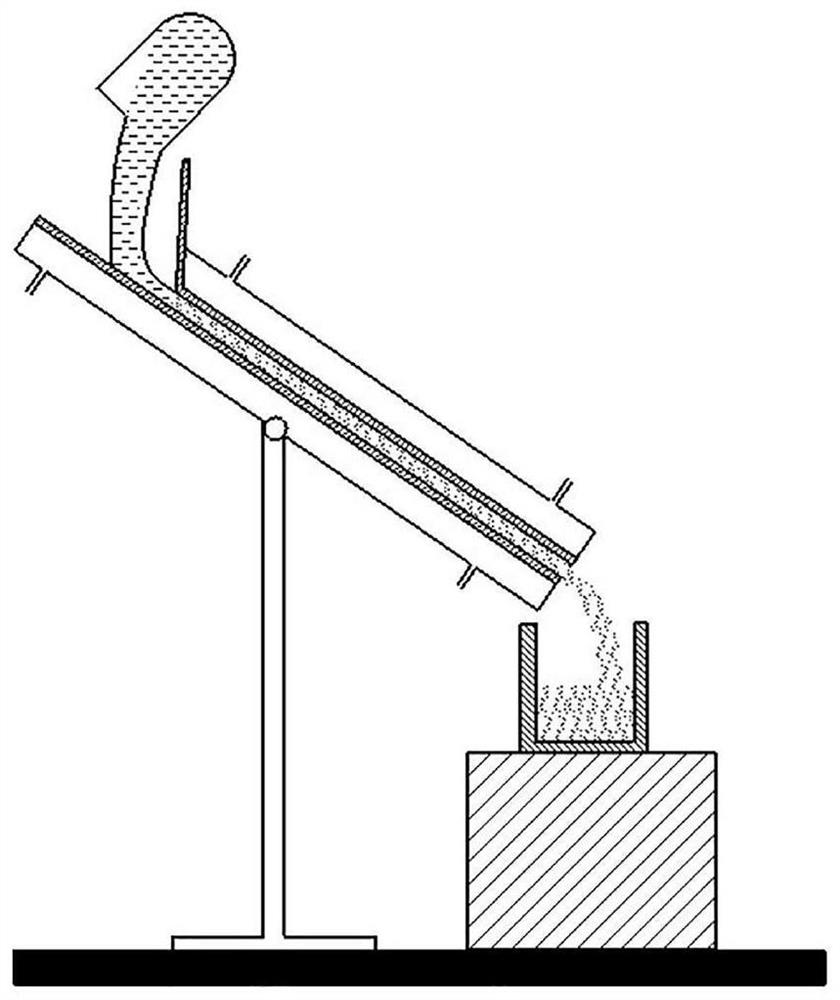

[0022] (2) Adjust the angle of the melt confinement flow induction nucleation device to 60°, the length of the melt confinement channel is 400mm, the flow rate of the upper and lower circulation cooling water is 500L / h, the collection crucible is preheated to 990°C, and the melt The cooling rate is about 400°C / s and the subcooling degree is about 20°C.

[0023] (3) The melt with a uniform temperature field is poured into the restricted cool...

Embodiment 2

[0029] The material composition described in this embodiment is CuSn8Fe1P0.8 (wt.%), and the specific preparation method is as follows:

[0030] (1) Weigh about 6kg of pure copper, copper-tin master alloy, copper-iron master alloy, and copper-phosphorus master alloy, heat the alloy rapidly to 1380°C for 20min in an intermediate frequency induction heating furnace, and then air cool to 1100°C (liquidus line 1028 °C) for degassing and slag removal and standing for 5 minutes to homogenize the internal temperature field of the alloy melt.

[0031] (2) Adjust the angle of the melt confinement flow induction nucleation device to 45°, the length of the melt confinement channel is 300mm, the flow rate of the upper and lower circulation cooling water is 600L / h, the collection crucible is preheated to 980°C, and the melt is cooled during the melt treatment The rate is about 2000°C / s and the degree of subcooling is about 50°C.

[0032] (3) The melt with a uniform temperature field is po...

Embodiment 3

[0039] The material composition described in this embodiment is CuSn14Fe6P1.2 (wt.%), and the specific implementation steps are as follows:

[0040] (1) Weigh about 8 kg of pure copper, copper-tin master alloy, copper-iron master alloy, and copper-phosphorus master alloy, rapidly heat the alloy to 1300°C for 3 minutes in a medium-frequency induction heating furnace, and then air-cool to 1050°C (liquidus line 1028 °C) degassing and slag removal and standing for 1min to make the internal temperature field of the alloy melt uniform;

[0041] (2) Adjust the angle of the melt confinement flow induction nucleation device to 50°, the length of the melt confinement channel is 350mm, the flow rate of the upper and lower circulation cooling water is 550L / h, and the collection crucible is preheated to 970°C. The cooling rate is about 800°C / s and the subcooling degree is about 100°C.

[0042] (3) The melt with a uniform temperature field is poured into the restricted cooling channel for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com