Air conditioner compressor discharge pipe joint assembly and manufacturing method thereof

A technology of air-conditioning compressor and manufacturing method, which is applied to manufacturing tools, pump components, welding equipment, etc., can solve problems such as low production efficiency, harm to employees, affecting airtight performance of brazing, etc., and achieves extended service life and consistency. Good, ensure the effect of brazing strength and airtight performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

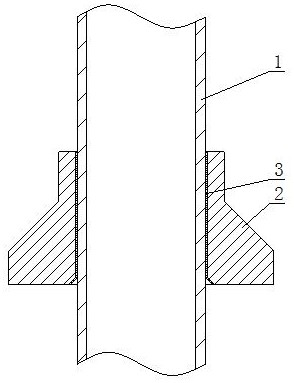

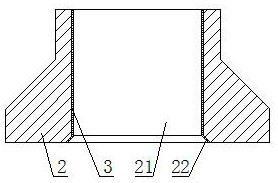

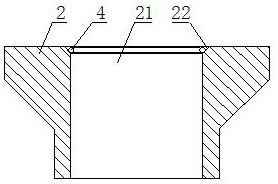

[0028] Such as figure 1 and figure 2 As shown, the air conditioner compressor exhaust pipe joint assembly includes an exhaust copper pipe 1 and a steel flange, the exhaust copper pipe 1 is fixedly connected to the steel flange by phosphor copper brazing, and the steel flange includes a steel flange body 2, The steel flange body 2 is axially provided with a through hole 21 for passing through the exhaust copper pipe 1. The through hole 21 is located at the large end surface of the steel flange body 2 and is provided with a conical surface 22. The surface of the conical surface 22 and the steel flange body 2 and the exhaust copper pipe 1 are provided with a copper-tin alloy layer 3, so that the subsequent component can be used for hydrogen protection brazing under the condition that the phosphorus copper solder does not exceed the recrystallization temperature of the exhaust copper pipe 1, and there is no harmful gas emission , green and environmental protection, good consiste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com