Directional solidification preparation method of high-tin-content and high-plasticity copper-tin alloy

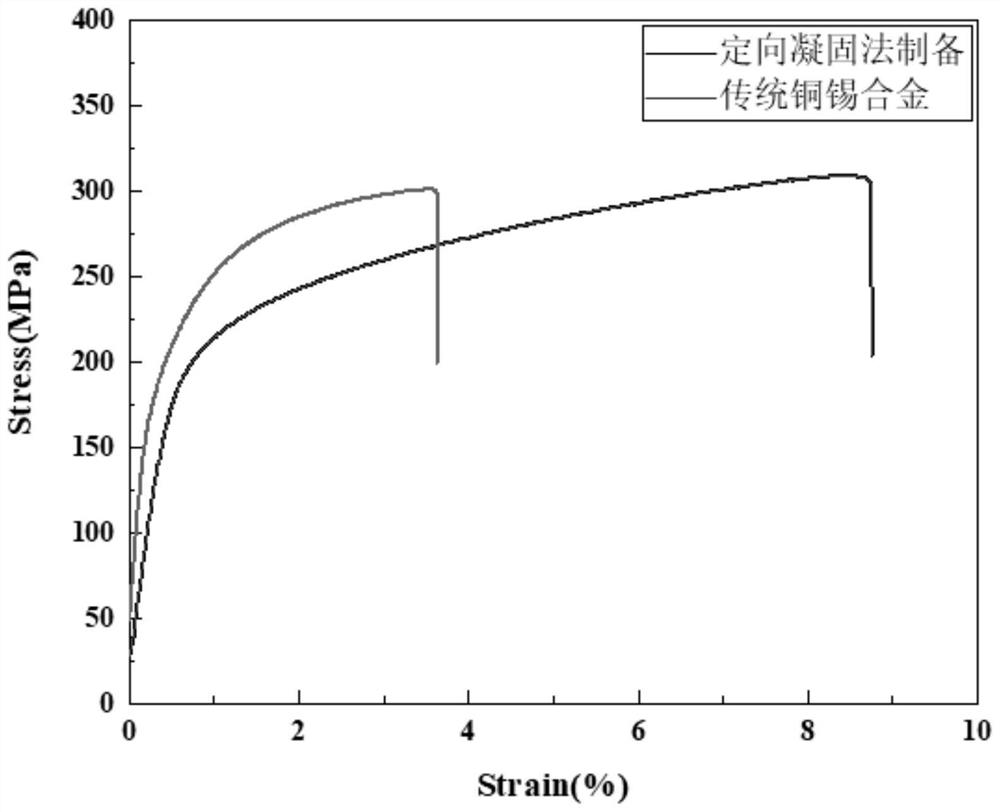

A technology of copper-tin alloy and directional solidification, which is applied in the field of preparing copper alloy materials by directional solidification, can solve the problems of low tin solid solubility and poor plasticity and toughness of materials, and achieve poor density, high plasticity and toughness, and good comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

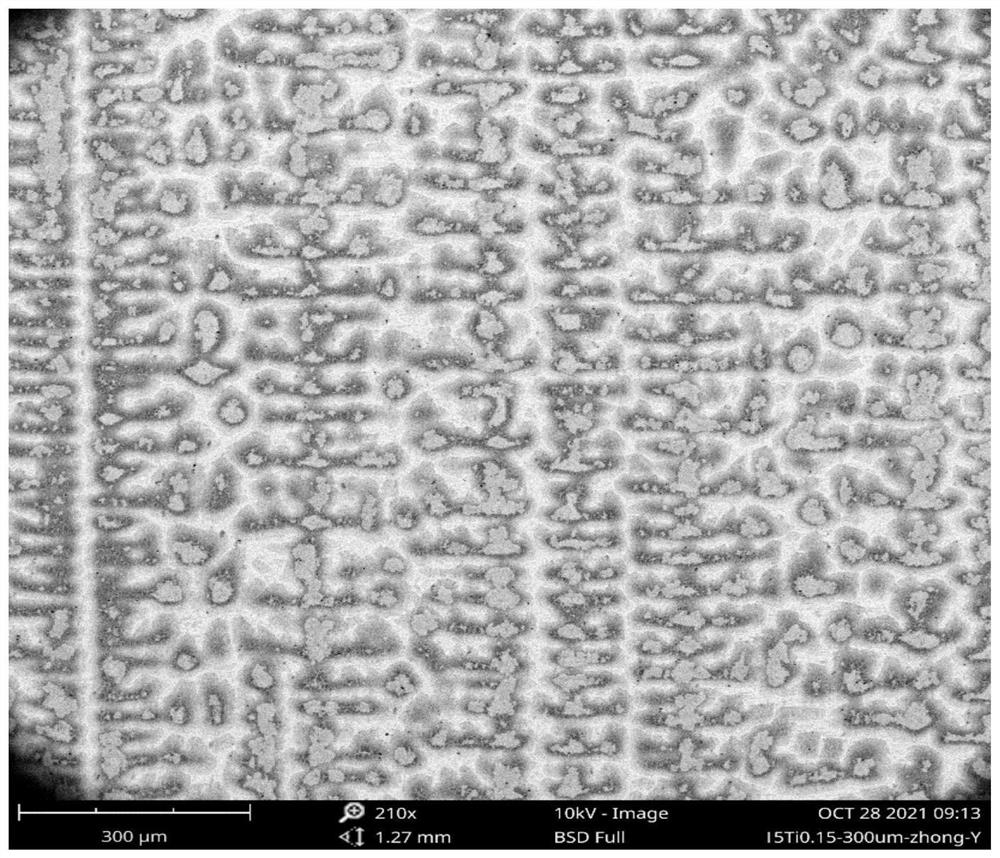

Image

Examples

Embodiment 1

[0031] Preliminary preparation of raw materials: Weigh 84.2% of Cu blocks, 15.5% of Sn particles, and 0.3% of Ti particles, and cut the Cu blocks into square blocks with a size of 40×40×40mm by wire cutting. Surface treatment of the treated material, use 400# sandpaper to clean the oxide scale on the surface of the copper block, then put the surface-treated copper block into a beaker, add an appropriate amount of ethanol solution or ultrasonic cleaning solution to the beaker, and then put it in the beaker. Clean in an ultrasonic cleaner for 15-20min, take out, rinse and dry;

[0032] Put the prepared materials into the magnesia crucible according to the density difference of each component of copper, tin and titanium in turn, put the magnesia crucible into the directional solidification furnace, adjust the pouring position and height of the cylindrical graphite crucible, and use cotton yarn containing alcohol. Wipe the contact between the furnace door and the furnace body, ens...

Embodiment 2

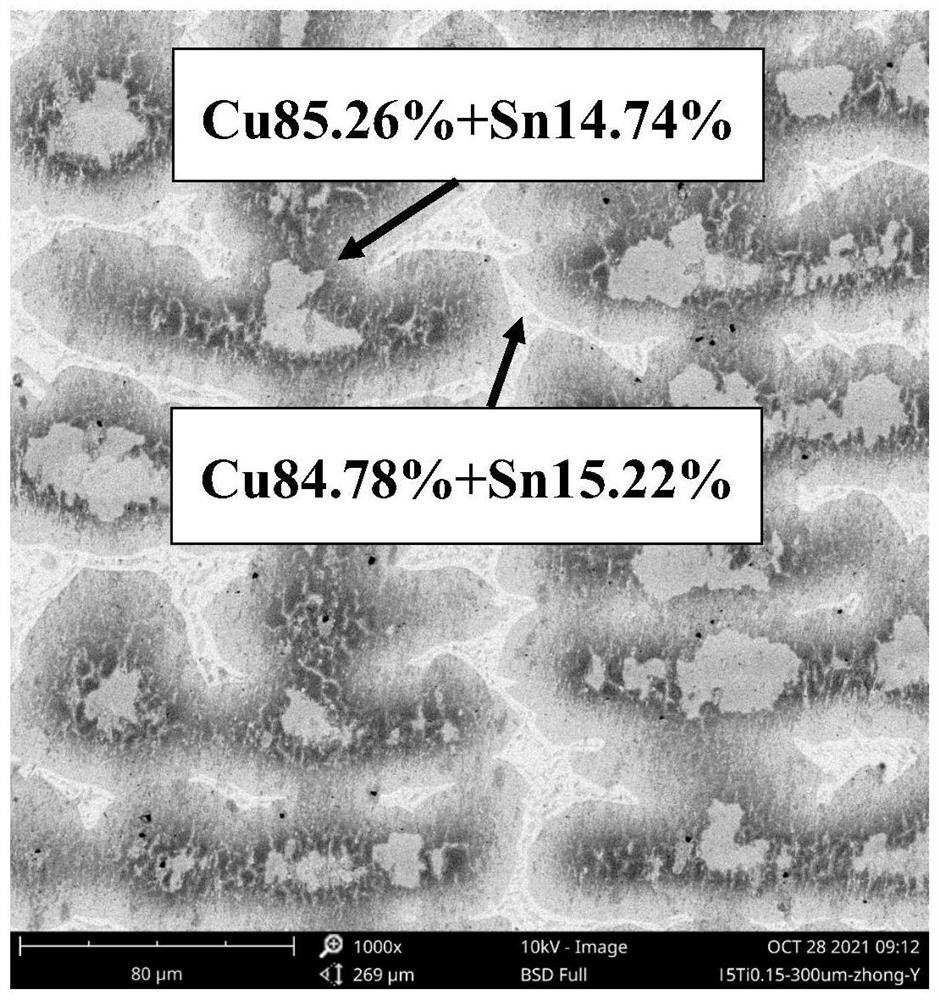

[0036] Preliminary preparation of raw materials: Weigh 84.5% of Cu blocks, 15.2% of Sn particles, and 0.3% of Ti particles, and cut the Cu blocks into square blocks with a size of 40×40×40mm by wire cutting. Surface treatment of the treated material, use 400# sandpaper to clean the oxide scale on the surface of the copper block, then put the surface-treated copper block into a beaker, add an appropriate amount of ethanol solution or ultrasonic cleaning solution to the beaker, and then put it in the beaker. Clean in an ultrasonic cleaner for 15-20min, take out, rinse and dry;

[0037] Put the prepared materials into the magnesia crucible according to the density difference of each component of copper, tin and titanium in turn, put the magnesia crucible into the directional solidification furnace, adjust the pouring position and height of the cylindrical graphite crucible, and use cotton yarn containing alcohol. Wipe the contact between the furnace door and the furnace body, ens...

Embodiment 3

[0041] Preliminary preparation of raw materials: Weigh 84.7% of Cu blocks, 15.0% of Sn particles, and 0.3% of Ti particles, and cut the Cu blocks into square blocks with a size of 40×40×40mm by wire cutting. Surface treatment of the treated material, use 400# sandpaper to clean the oxide scale on the surface of the copper block, then put the surface-treated copper block into a beaker, add an appropriate amount of ethanol solution or ultrasonic cleaning solution to the beaker, and then put it in the beaker. Clean in an ultrasonic cleaner for 15-20min, take out, rinse and dry;

[0042] Put the prepared materials into the magnesia crucible according to the density difference of each component of copper, tin and titanium in turn, put the magnesia crucible into the directional solidification furnace, adjust the pouring position and height of the cylindrical graphite crucible, and use cotton yarn containing alcohol. Wipe the contact between the furnace door and the furnace body, ens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com