Method for recovering and regenerating refined tin from tin foil ash

A technology of tin foil ash and soot, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of large pollution and low tin recovery rate, and achieve the effects of small pollution, reduced tin loss, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

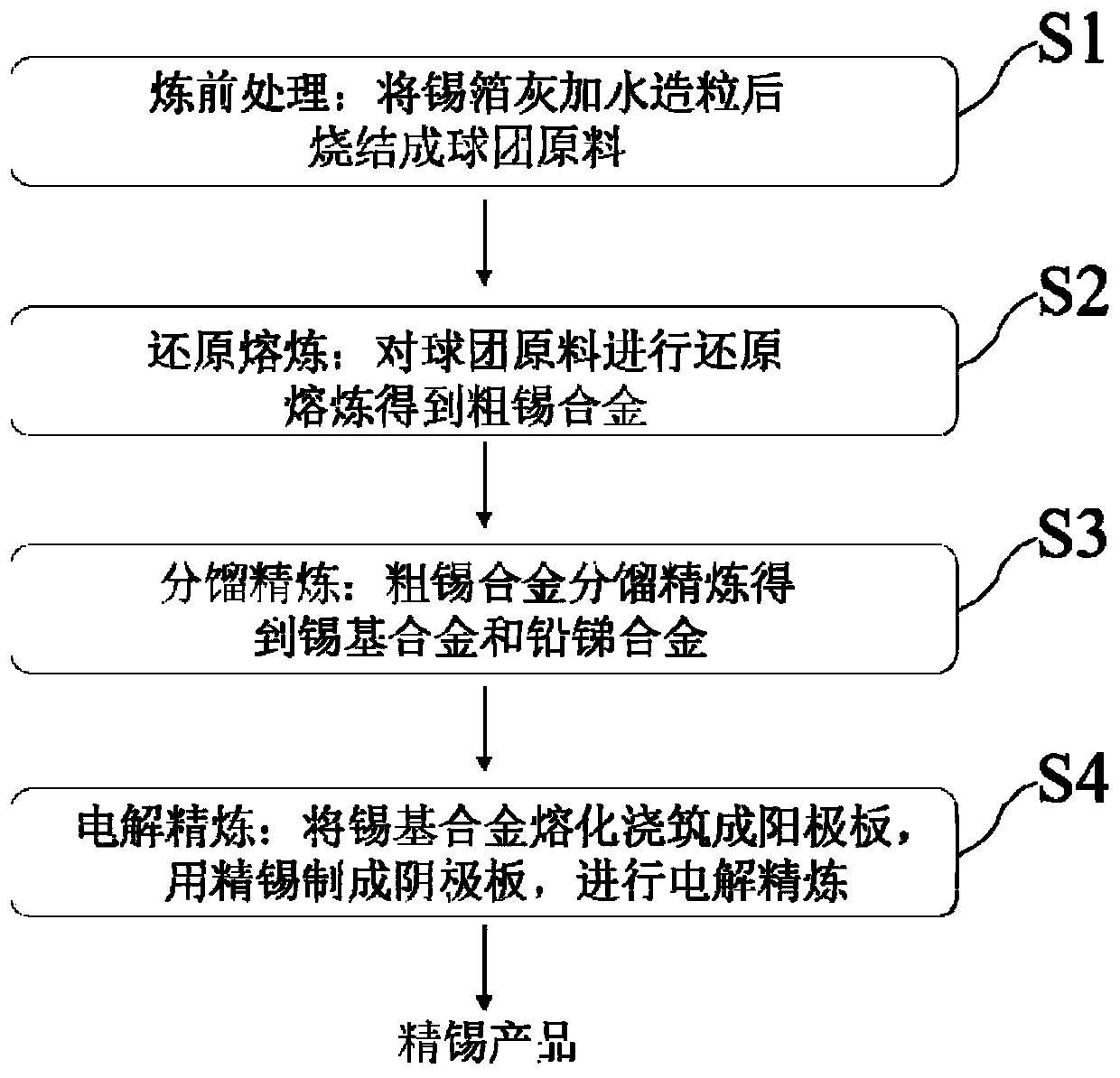

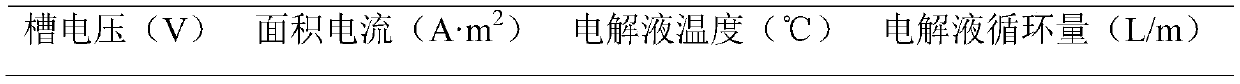

[0059] Such as figure 1 As shown, the method for reclaiming regenerated refined tin from tin foil ash in this embodiment is to add 30 tons of tin foil ash containing 35% Sn to 3 tons of water and stir it into pellets in a disc granulator. The pellets are fed into the rotary kiln, the kiln is 20m long, 1.8m in diameter, 2-3° inclination, 1 rpm, heated and sintered with natural gas in the rotary kiln, the temperature is 500℃, moisture and combustibles are removed, and sintered balls are obtained. 28.5 tons of lump raw materials and 1.5 tons of soot;

[0060] Take 10 tons of sintered tin foil ash pellets as raw material, add 0.8 tons of coal powder, 0.3 tons of quartz sand and 0.3 tons of limestone, and add them to the submerged electric furnace for reduction smelting. The bottom of the furnace is covered with a coke layer with a particle size of 25mm and a thickness of 250mm. Inserted at a distance of 150mm from the coke layer, the temperature reached 900°C for smelting, and t...

Embodiment 2

[0073] Such as figure 1 As shown, the method for recovering regenerated refined tin from tin foil ash in this embodiment is to add 30 tons of tin foil ash containing 38% Sn to 3.6 tons of water and stir it into pellets in a disc granulator. The pellets are sent to the rotary kiln, the kiln is 20m long, 1.8m in diameter, 2-3° inclination, 1 rev / min, heated and sintered with natural gas in the rotary kiln, the temperature is 550°C, moisture and combustibles are removed, and sintered balls are obtained. 28.65 tons of lump raw materials and 1.35 tons of soot;

[0074] Take 10 tons of sintered tin foil ash pellet raw materials, add 0.9 tons of coal powder, 0.5 tons of quartz sand and 0.5 tons of limestone, and add them to the submerged electric furnace for reduction smelting. The bottom of the furnace is covered with a coke layer with a particle size of 45mm and a thickness of 280mm. Inserted at a distance of 150mm from the coke layer, the temperature reached 1000°C for smelting,...

Embodiment 3

[0087] Such as figure 1 As shown, the method for recovering regenerated refined tin from tin foil ash in this embodiment is to add 30 tons of tin foil ash containing 40% Sn to 4.5 tons of water and stir it into pellets in a disc granulator. The pellets are then sent to the rotary kiln, the kiln is 20m long, 1.8m in diameter, 2-3° inclination, 1 rev / min, heated and sintered with natural gas in the rotary kiln, the temperature is 600℃, moisture and combustibles are removed, and sintered balls are obtained 28.8 tons of lump raw materials and 1.2 tons of soot;

[0088] Take 10 tons of sintered tin foil ash pellet raw materials, add 1.0 tons of coal powder, 0.6 tons of quartz sand and 0.6 tons of limestone, and add them to the submerged thermal electric furnace for reduction smelting. Inserted at a distance of 150mm from the coke layer, the temperature reached 1100°C for smelting, and the feeding was divided into three times, the first feeding was 4 tons, the second feeding was 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com