Zirconium alloy for cladding material of nuclear fuel element in non-hydrogenated deoxidization pressurized water reactor

A technology for nuclear fuel elements and cladding materials, applied in the field of zirconium alloy materials, can solve problems such as corrosion acceleration and sensitivity to dissolved oxygen concentration, and achieve the effects of reducing tin content, excellent corrosion resistance, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

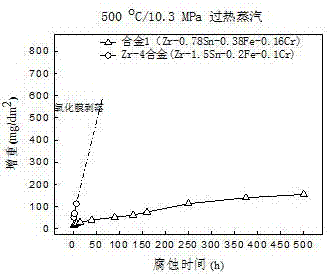

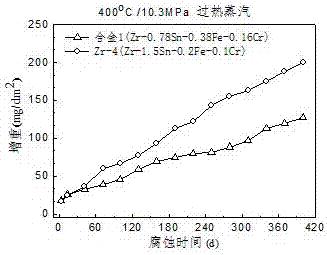

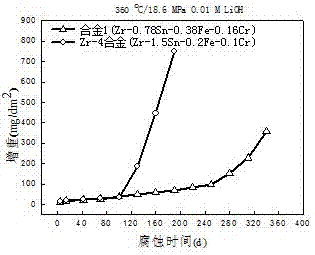

[0016] Embodiment one: see table 1, wherein provides the zirconium tin series alloy of the present invention and the composition of Zr-4 alloy:

[0017] .

[0018] The alloy materials with the composition in Table 1 were prepared according to the following steps:

[0019] (1) According to the above formula and ingredients, entrust the factory to prepare alloy ingots with a weight of about 20 kg by conventional techniques;

[0020] (2) Forge the above alloy ingot at 950~1050 ℃ to form a billet, and at the same time break the coarse as-cast grain structure;

[0021] (3) After descaling and pickling, the billet is subjected to β-phase homogenization treatment at 1030-1050 °C in vacuum for 0.5-1 h and then air-cooled; then it is hot-rolled at 700-800 °C, and the oxidation is removed first after hot-rolling. Skin;

[0022] (4) After the blank is air-cooled, it is subjected to multiple cold rolling and intermediate annealing at 580 °C, and finally recrystallization annealing at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com