Method for recovering tin in PCB production process

A production process and recovery method technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sewage treatment, etc., can solve the problems of low tin content and low recovery rate in products, and achieve high tin content in products , low recycling cost, high recovery rate and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

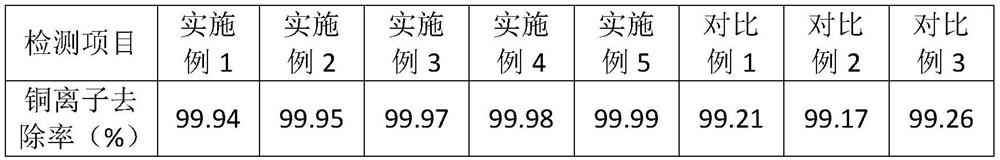

Examples

Embodiment 1

[0039] Embodiment 1 provides a kind of recovery method of tin in PCB production process, it is characterized in that, comprises the steps:

[0040] Step S1, alkali pretreatment: put the tin stripping waste water generated in the PCB production process into the alkaline solution, and stir evenly;

[0041] Step S2, heavy metal treatment agent treatment: add heavy metal treatment agent and flocculant to the PCB tin stripping wastewater after alkali pretreatment in step S1, stir evenly, ultrasonicate for 15 minutes, then microwave for 10 minutes, settle, filter and separate, Washing and drying to obtain tin-rich products;

[0042] Step S3, cation exchange resin treatment: the filtrate treated in step S2 is adsorbed with a cation exchange resin for metal cations, and then separated by filtration, washed with water, and dried to obtain a tin-rich cation exchange resin;

[0043] Step S4, anti-capture: adding dilute nitric acid with a mass percent concentration of 3-5% to the tin-ric...

Embodiment 2

[0052] Embodiment 2 provides a method for recovering tin in the PCB production process, which is basically the same as Embodiment 1, except that the heavy metal treatment agent is made from the following components in parts by weight: hyperbranched sulfonic acid 6 parts of salt surfactant SHBP-1, 3.5 parts of polyphosphoric acid, and 1.5 parts of ammonium phosphate; the flocculant is made from the following components in parts by weight: 3.5 parts of amino-terminated water-soluble hyperbranched polyamide, 4.5 parts of polyferric sulfate, 3.5 parts of alum.

Embodiment 3

[0054] Embodiment 3 provides a method for recovering tin in the PCB production process, which is basically the same as Embodiment 1, except that the heavy metal treatment agent is made from the following components in parts by weight: hyperbranched sulfonic acid 6.5 parts of salt surfactant SHBP-1, 4 parts of polyphosphoric acid, and 2 parts of ammonium phosphate; the flocculant is made from the following components in parts by weight: 4 parts of amino-terminated water-soluble hyperbranched polyamide, 5 parts of polyferric sulfate, 4 parts of alum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com