Anti-fatigue orthotropic plate structure and producing process

An orthotropic plate and production process technology, applied in the field of steel structure bridges and shipbuilding, to achieve the effect of extending the service life, improving the overall fatigue resistance and increasing the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

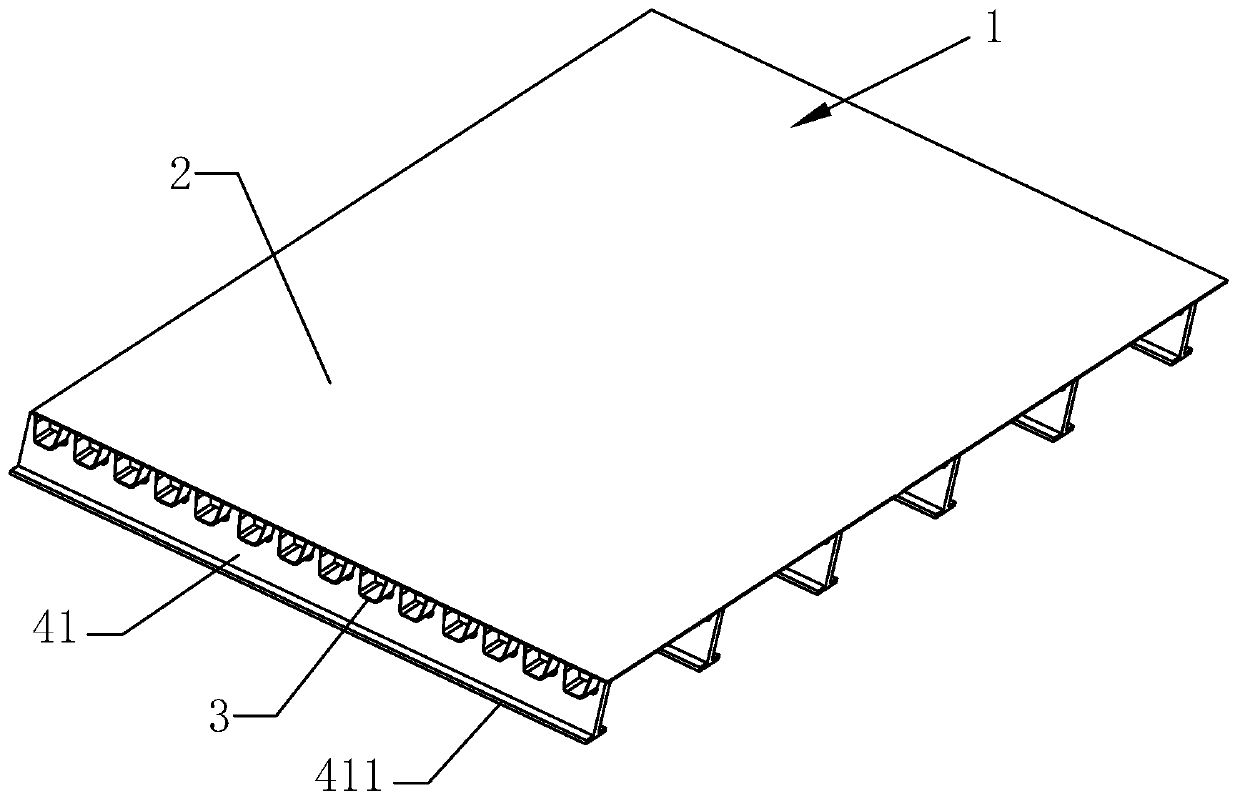

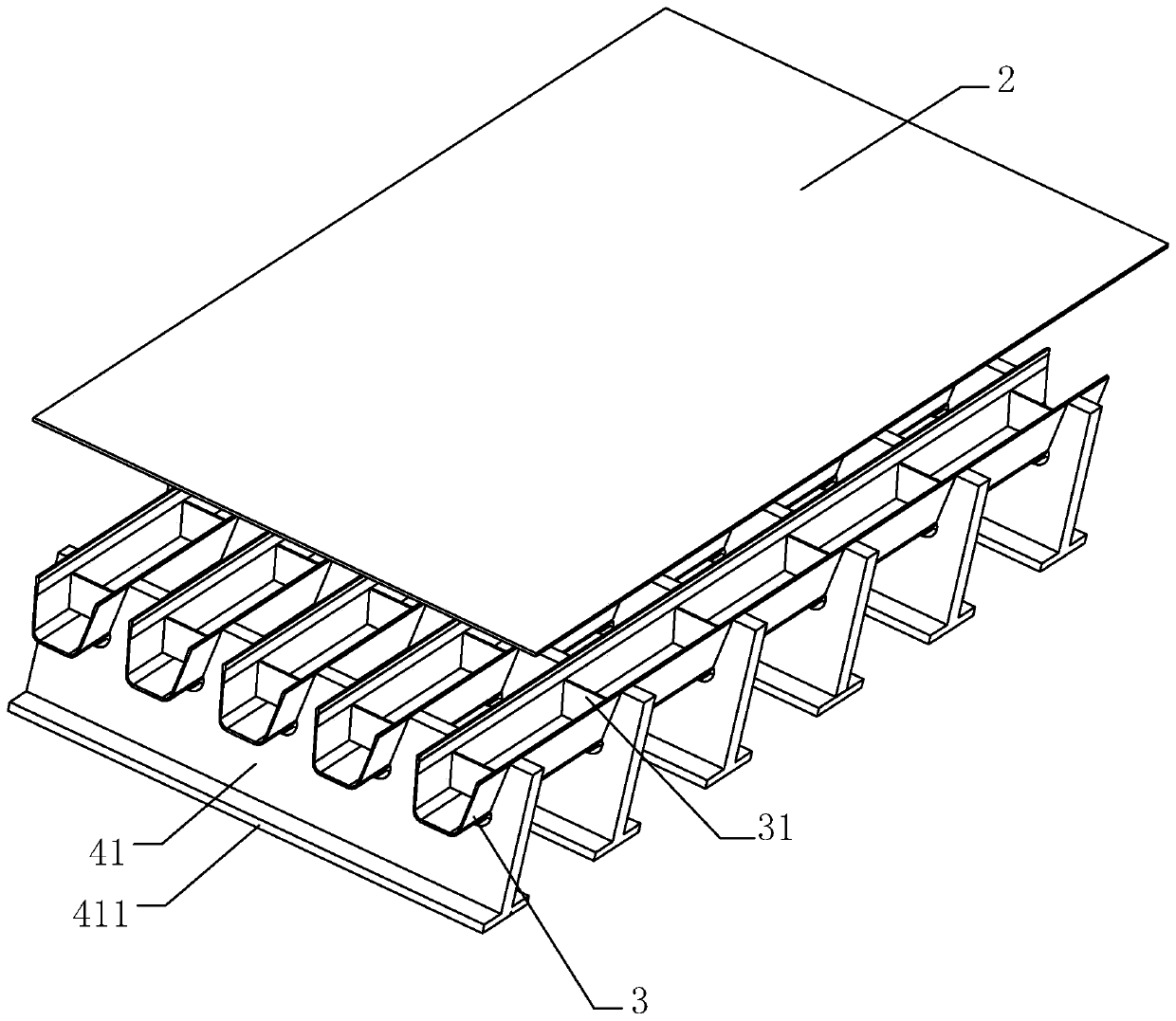

[0042] combine figure 1 and figure 2 , is a fatigue-resistant orthotropic plate structure that greatly reduces residual welding stress disclosed in the present invention. The anti-fatigue orthotropic plate structure includes orthotropic plates. The orthotropic plate includes steel panels 2, multiple longitudinal stiffeners 3 and multiple transverse diaphragms 4. The bottom of the steel panel 2 is welded with multiple sets of longitudinal stiffeners 3 at equal intervals. . The diaphragm 4 is divided into a top diaphragm 41 and a bottom diaphragm 42 (refer to Figure 4 ), the top transverse diaphragm 41 is welded vertically to the bottom surface of the steel panel 2, and welded to the outer wall of the longitudinal stiffener 3, and the longitudinal stiffener 3 is perpendicular to the transverse diaphragm 4. Compared with the traditional heterosexual plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com