High-strength thick-wall welded steel pipe for deep sea pipeline and production method thereof

A technology for welding steel pipes and manufacturing methods, which is applied in the direction of manufacturing tools, welding equipment, applications, etc., and can solve problems such as increased corrosion and complex corrosion behavior of steel pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

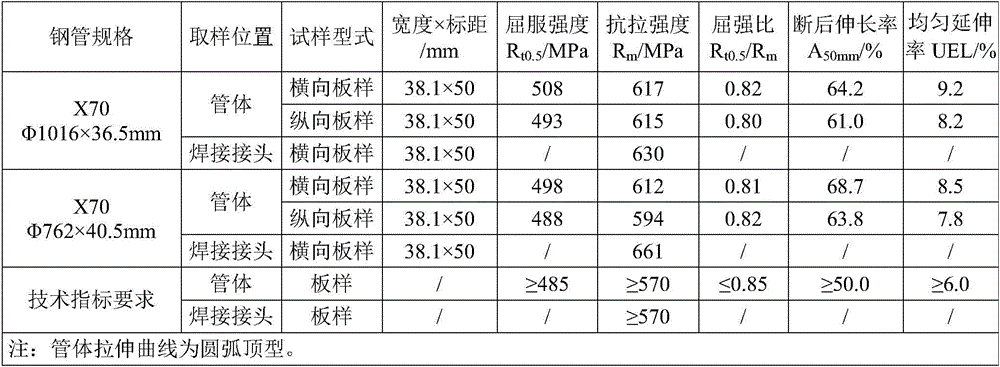

[0040] Combining the manufacturing examples of X70Φ1016mm×36.5mm and X70Φ762mm×40.5mm thick-walled deep-sea pipeline linear submerged arc welded pipe welding joints, the embodiments of the present invention are as follows:

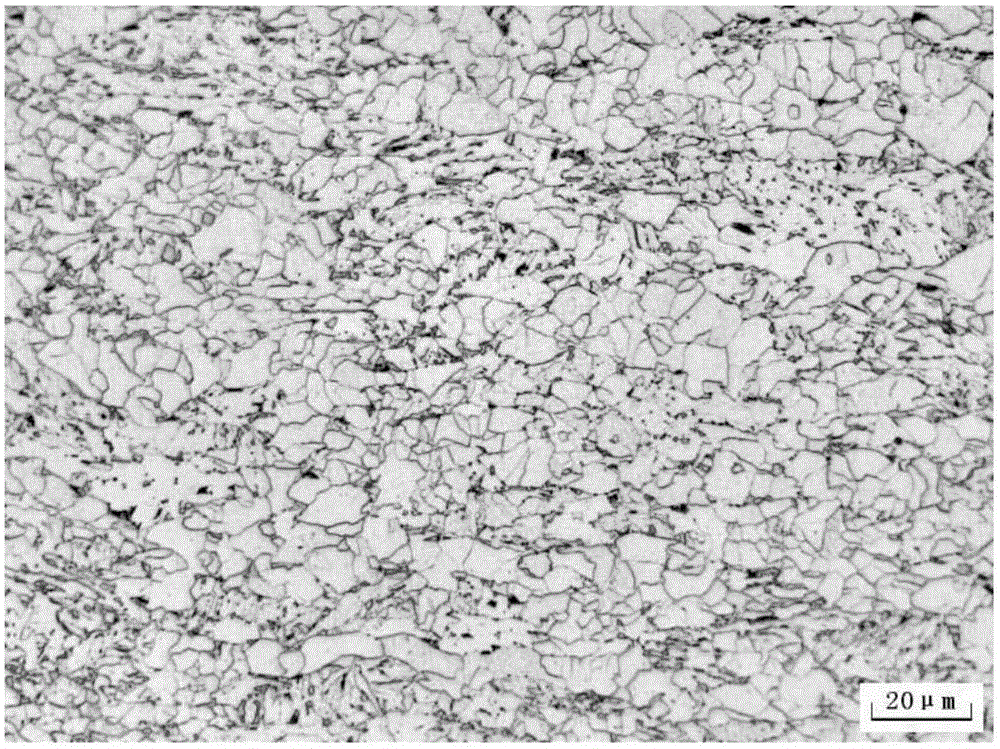

[0041] 1. Development of high-strength thick-walled welded steel pipe plates with a wall thickness of 36.5mm to 40.5mm for deep-sea pipelines with high plasticity and corrosion resistance. According to mass percentage, containing C: 0.03% ~ 0.07%, Si: 0.10% ~ 0.40%, Mn: 1.20% ~ 1.60%, P≤0.012%, S≤0.0015%, Ni: 0.10% ~ 0.35%, Cr: 0.10 %~0.35%, Cu≤0.35%, Mo: 0.10%~0.35%, Nb: 0.01%~0.06%, V: 0.01%~0.06%, Ti: 0.005%~0.025%, Al: 0.01%~0.06%, N: 0.0020% to 0.0060%, Ca: 0.0005% to 0.0035%, Ti / N: 1.5 to 4.0, the rest is formed by Fe and unavoidable impurities, and the welding crack sensitivity index of the material is Pcm≤0.19. The structure of pipeline steel plate is mainly composed of polygonal ferrite and bainite, such as figure 1 As shown, the bainite fractio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com