Method for guaranteeing uniformity of heat treatment of large-diameter thick-wall pipe weld

A thick-walled tube, uniform technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control and other directions, can solve problems such as poor practicability and poor operability, and achieve the effect of strong real-time performance, easy operation, and improved performance of welded joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

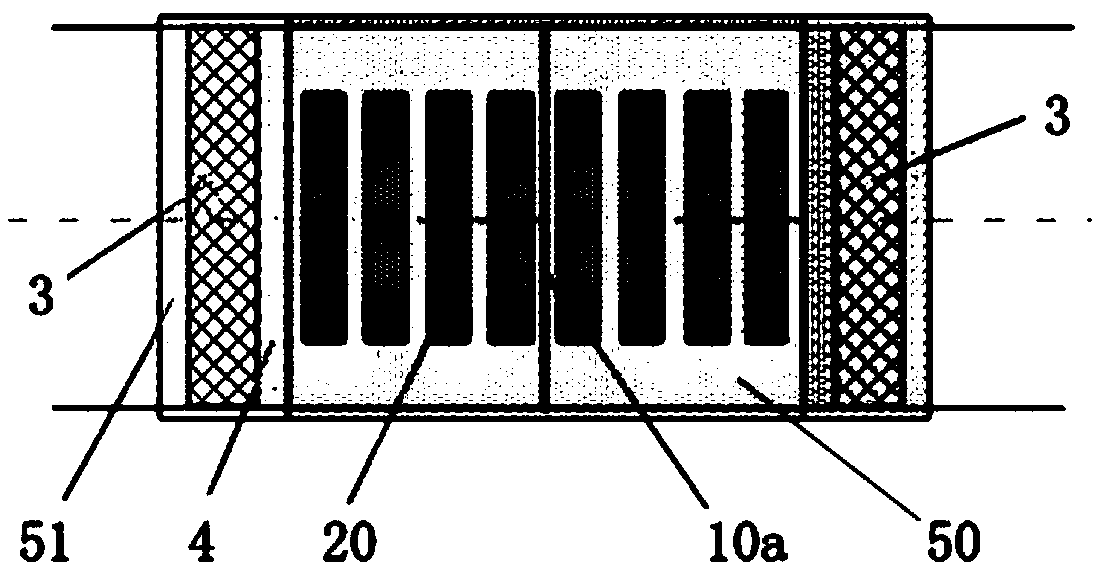

Method used

Image

Examples

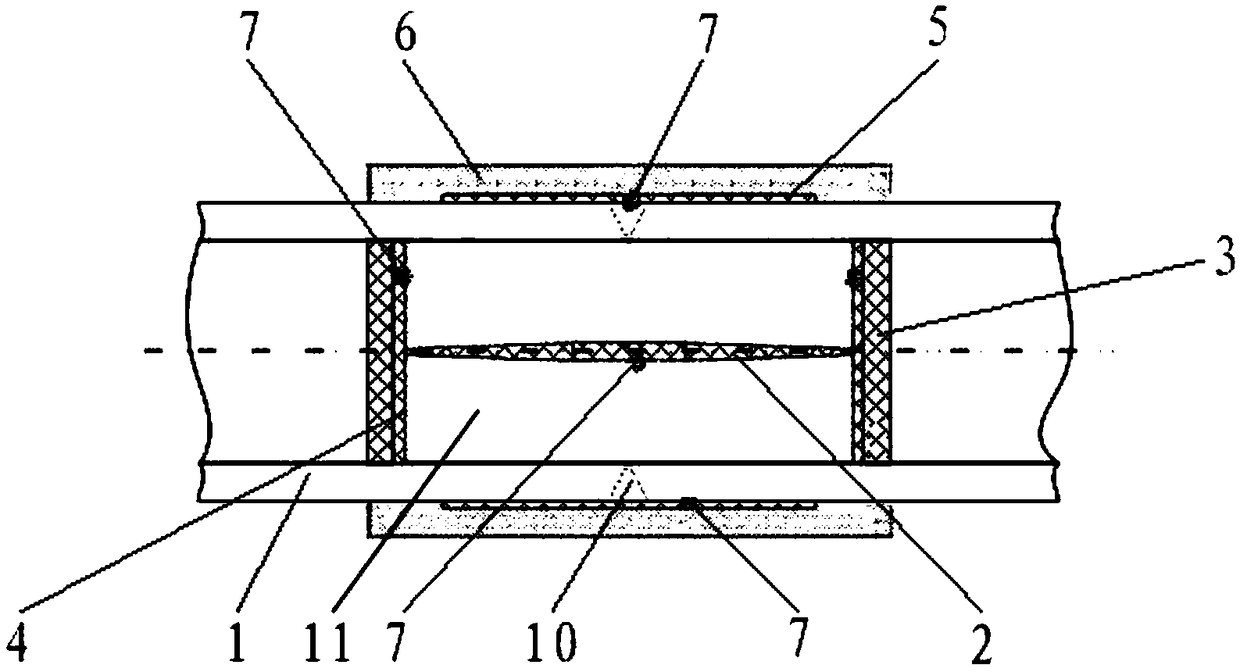

Embodiment 1

[0040] A steam drum cylinder of a pressure vessel is made of low alloy steel SA-299, with an inner diameter of Φ1778mm, an upper wall thickness of 196.1mm, a lower wall thickness of 163.9mm, and a total length of 28.91m including the heads on both sides. There are two girth welds on it There are excessive defects such as cracks and inclusions, and some defects show penetration of the inner and outer walls. After the welding repair is completed, the process requires local post-weld heat treatment for the two repaired girth welds. The heat treatment temperature is required to be 550 ° C. The speed does not exceed 50°C / h.

[0041] Adopt the method of the present invention to carry out partial post-weld heat treatment to two girth welds, concrete implementation steps are as follows:

[0042] (1) Selection of heating power

[0043] According to the post-weld heat treatment process requirements, the heating power calculation formula P=KWC(T a -T b ) / 3600t . in, P Power requ...

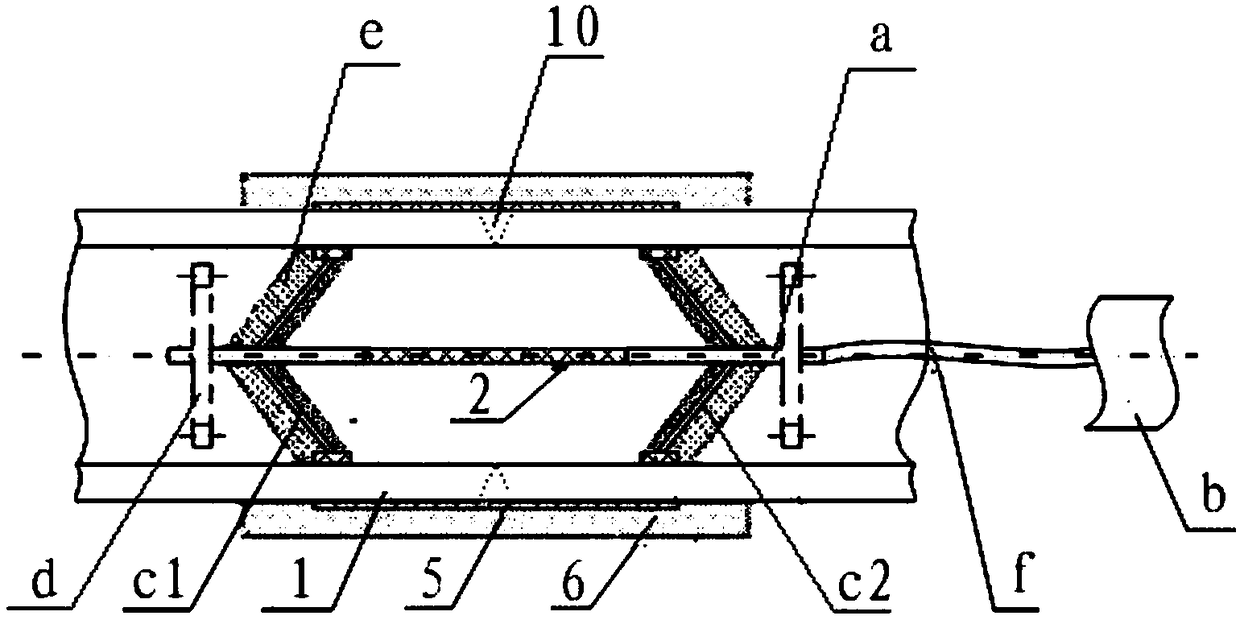

Embodiment 2

[0049] A steam drum cylinder of a pressure vessel is made of low-alloy steel SA-299, with an outer diameter of Φ2200mm, a wall thickness of 195mm, and a total length of 27.2m including the heads on both sides. The longitudinal weld between the 2nd and 3rd girth welds has excessive defects within 1.49m, and the defect position is 136-146mm away from the outer wall. The defects are eliminated from the inner wall, and the longitudinal weld is repaired after welding. Partial post-weld heat treatment, the constant temperature of heat treatment is required to be 550°C, and the heating and cooling rate should not exceed 50°C.

[0050] Adopt the method of the present invention to carry out partial post-weld heat treatment to two girth welds, concrete implementation steps are as follows:

[0051] (1) Selection of heating power

[0052] When the temperature rise rate of the post-weld heat treatment process is 50°C / h, the calculated power of the main heat source required for heating the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com