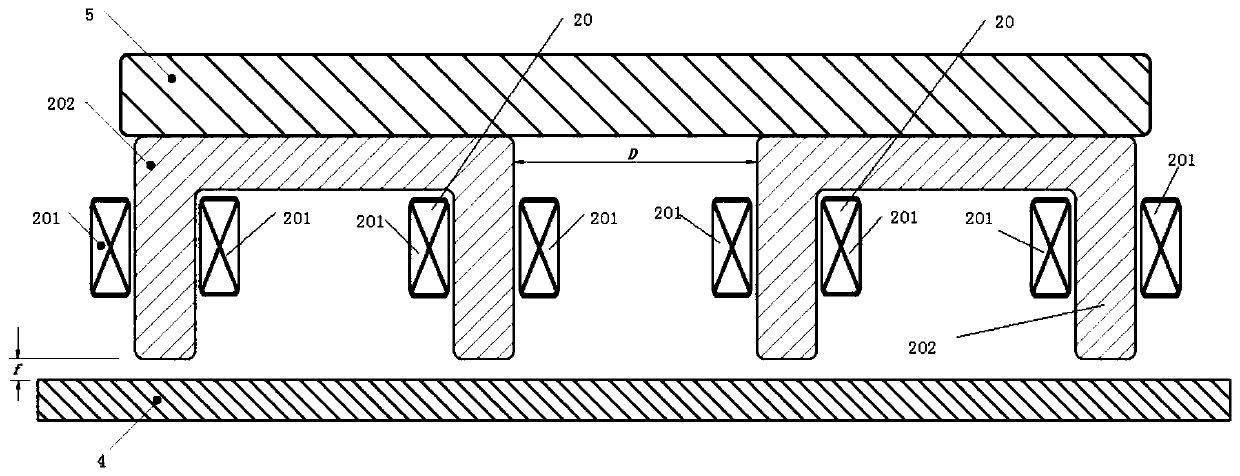

Device for eliminating welding residual stress based on electromagnetic energy

A technology of residual stress and electromagnetic energy, which is applied to the improvement of process efficiency, heat treatment equipment, furnace, etc., can solve the problems of low processing efficiency and high noise, and achieve the effect of improving efficiency, improving performance and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0049] Q690 steel plate is used as the welding base material, the size of the test plate is 500×200×15mm, and a “V”-shaped groove is made along the length direction at 1 / 2 of the width of the test plate, and the groove angle is 60°. The welding adopts argon-rich mixed gas shielded welding (MAG welding), the polarity is DC+, the welding wire is flux-cored wire CHT100CK3, and the welding process uses Ar+20% CO 2 Gas protection, gas purity over 99.98%. Table 1 is the chemical composition of the base metal and welding consumables, Table 2 is the mechanical properties of the materials, and Table 3 is the welding parameters. The blind hole stress release method is used for the measurement of welding residual stress. There are 6 measuring points located in the center of the weld, and the distance between the measuring points is >10mm.

[0050] Table 1 Chemical composition of base metal and welding consumables (mass fraction, %)

[0051]

[0052] Table 2 Mechanical properties of ...

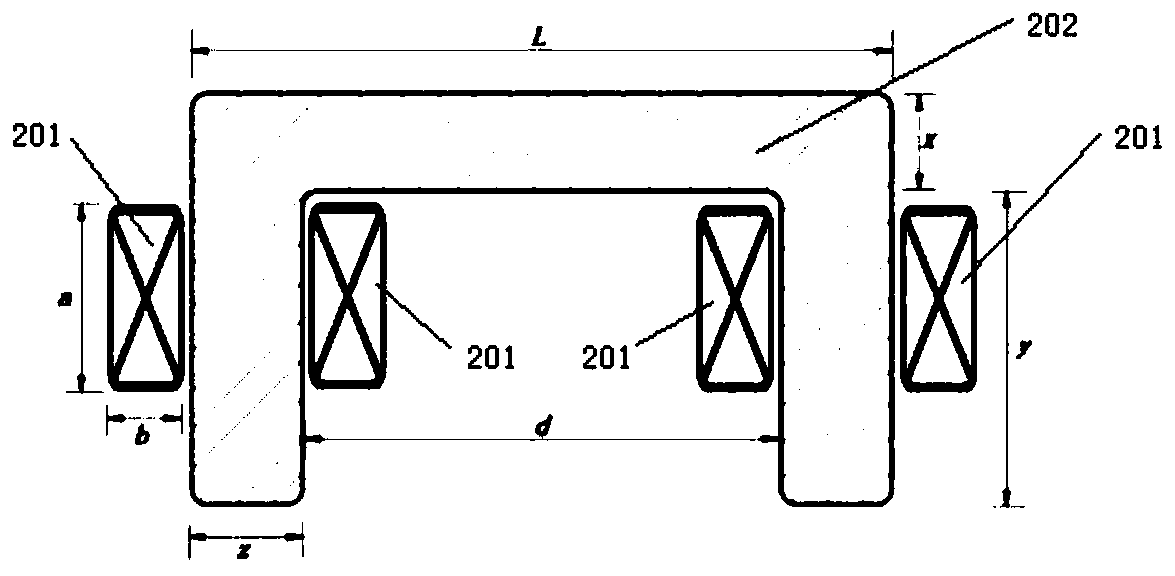

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com