Welding process special for thick dissimilar material plate

A welding process and material technology, which is applied in the field of welding for ultra-thick-walled dissimilar materials, can solve the problems of reduced impact toughness, large welding stress, and low welding efficiency, so as to reduce welding deformation, eliminate welding residual stress, and improve welding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

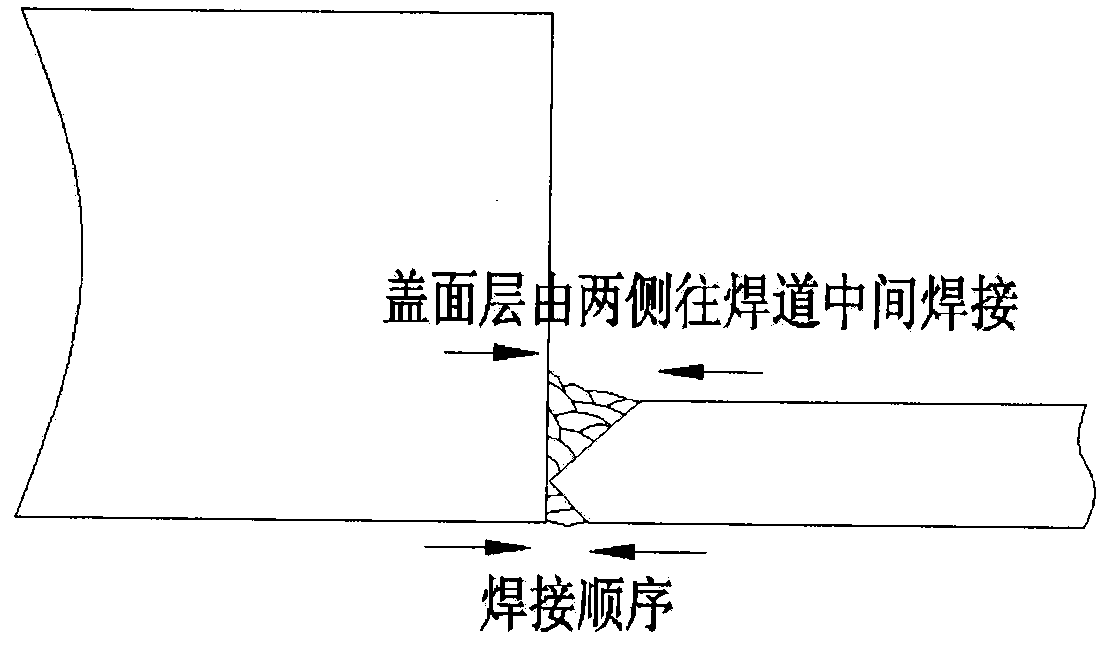

[0023] In the following, a detailed description is given by taking the base metal of 290mm thick S355J2+QT material and the welding material of 70mm thick DH36 material as examples.

[0024] 1 Selection of welding materials

[0025] 1.1 In order to improve the welding efficiency, it was decided to use CO with a diameter of 1.4mm 2 Welding with shielded wire.

[0026] 1.2 According to the matching requirements of the strength grade, and taking into account the need to meet the standard ISO15614-1, the welding wire adopts the GFL-71Ni flux-cored welding wire with a diameter of 1.4mm that meets the requirements of EN ISO 17632 A T 42 4 PC 1 H5 and is approved by ABS, containing Ni element to improve low temperature toughness and crack resistance.

[0027] 2 Preparation before welding

[0028] 2.1 Welding equipment

[0029] This process uses XD500SII CO 2 Welding machine, the welding machine comes with a digital display of current and voltage.

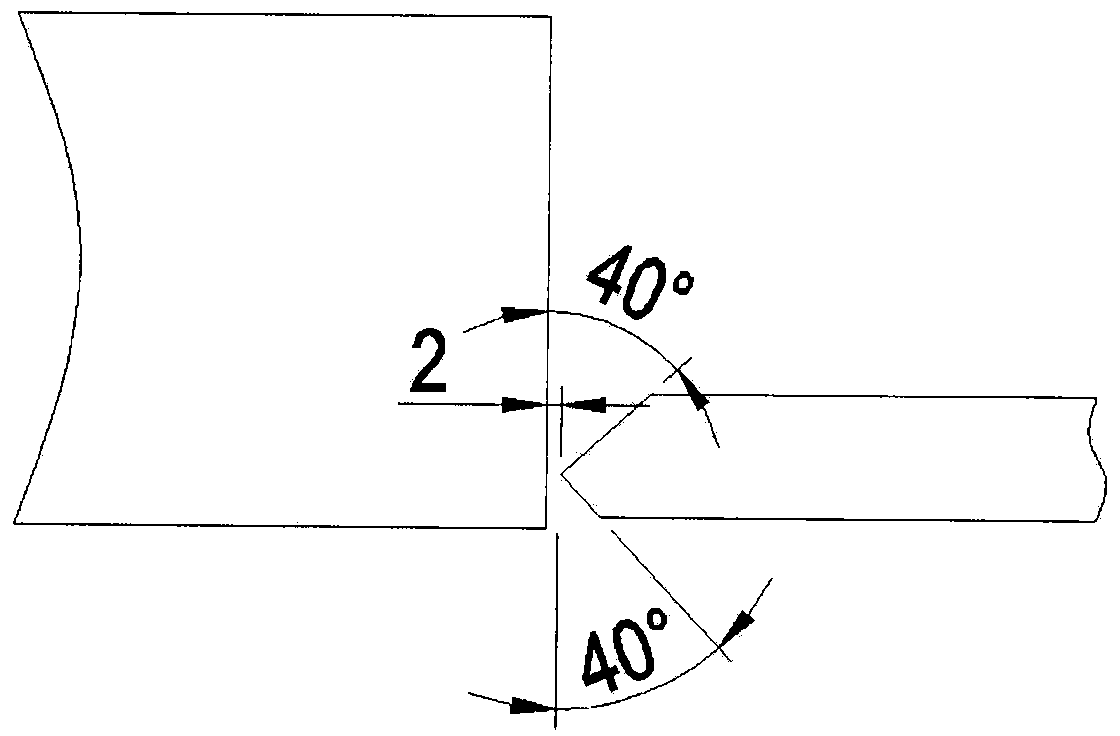

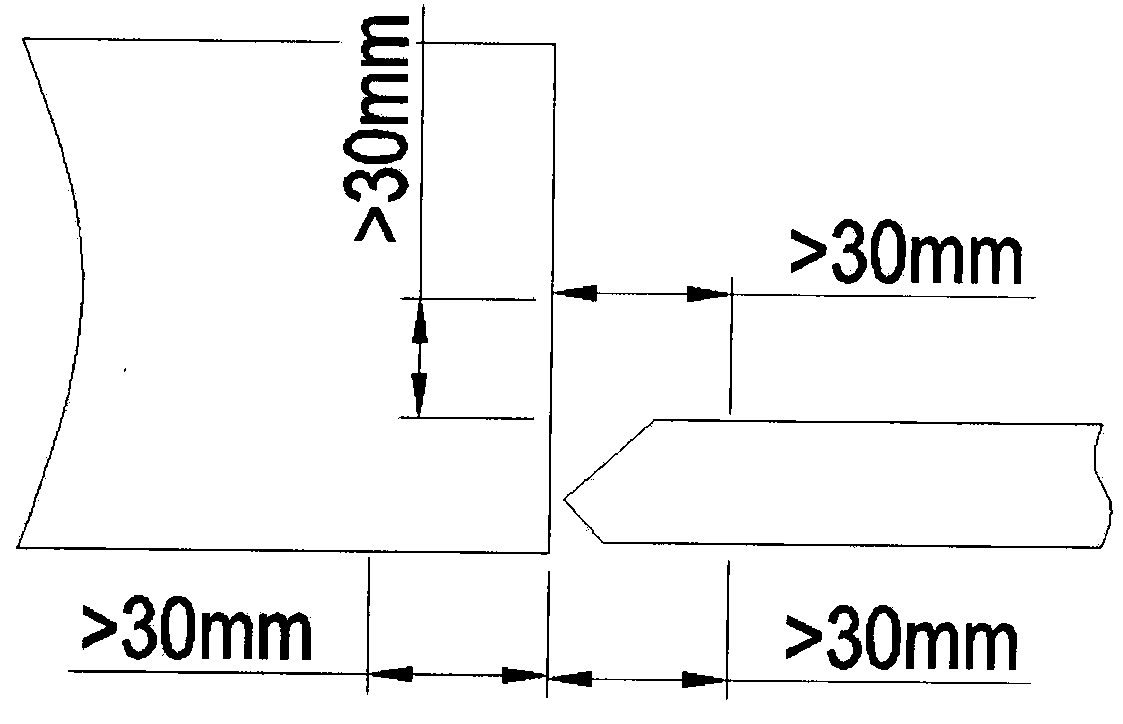

[0030] 2.2 Groove preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com