Welding technology method of lifting device box in self-lifting type drilling platform

A lifting device and drilling platform technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of high rigidity of modulated steel materials, high precision requirements for manufacturing structures, and prominent cracks, so as to eliminate residual stress and solve welding problems. Crack problem, effect of reducing welding heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

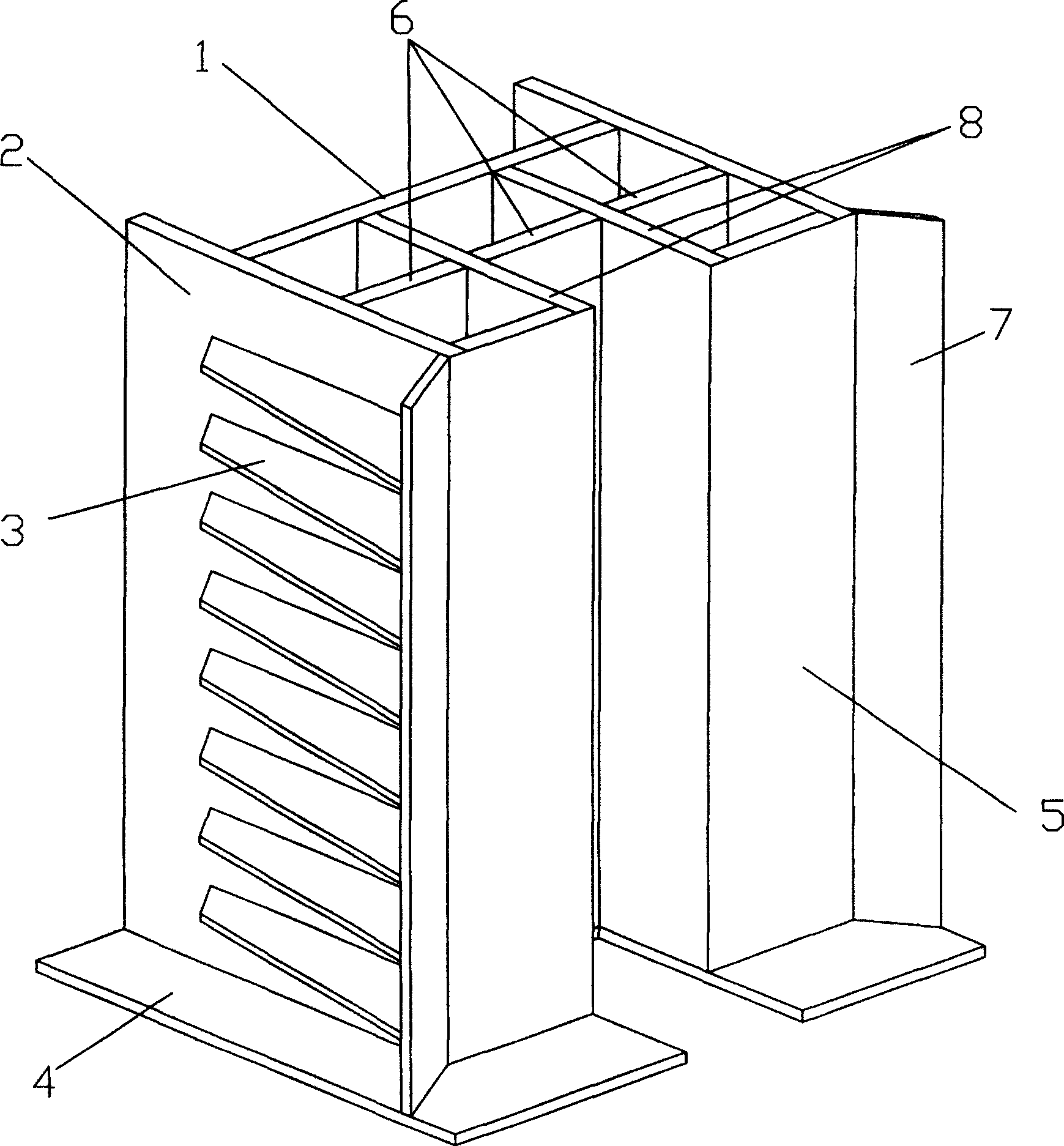

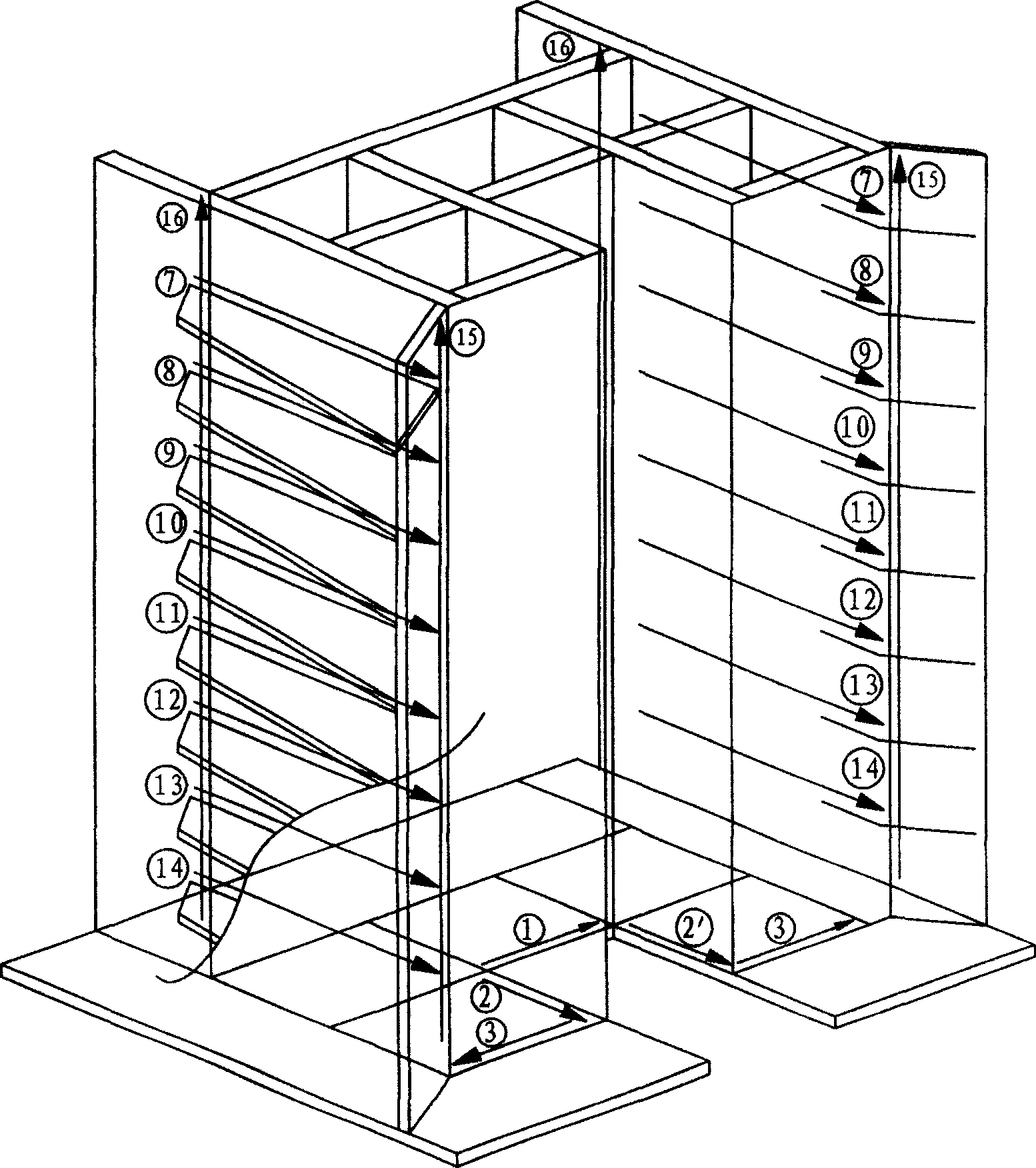

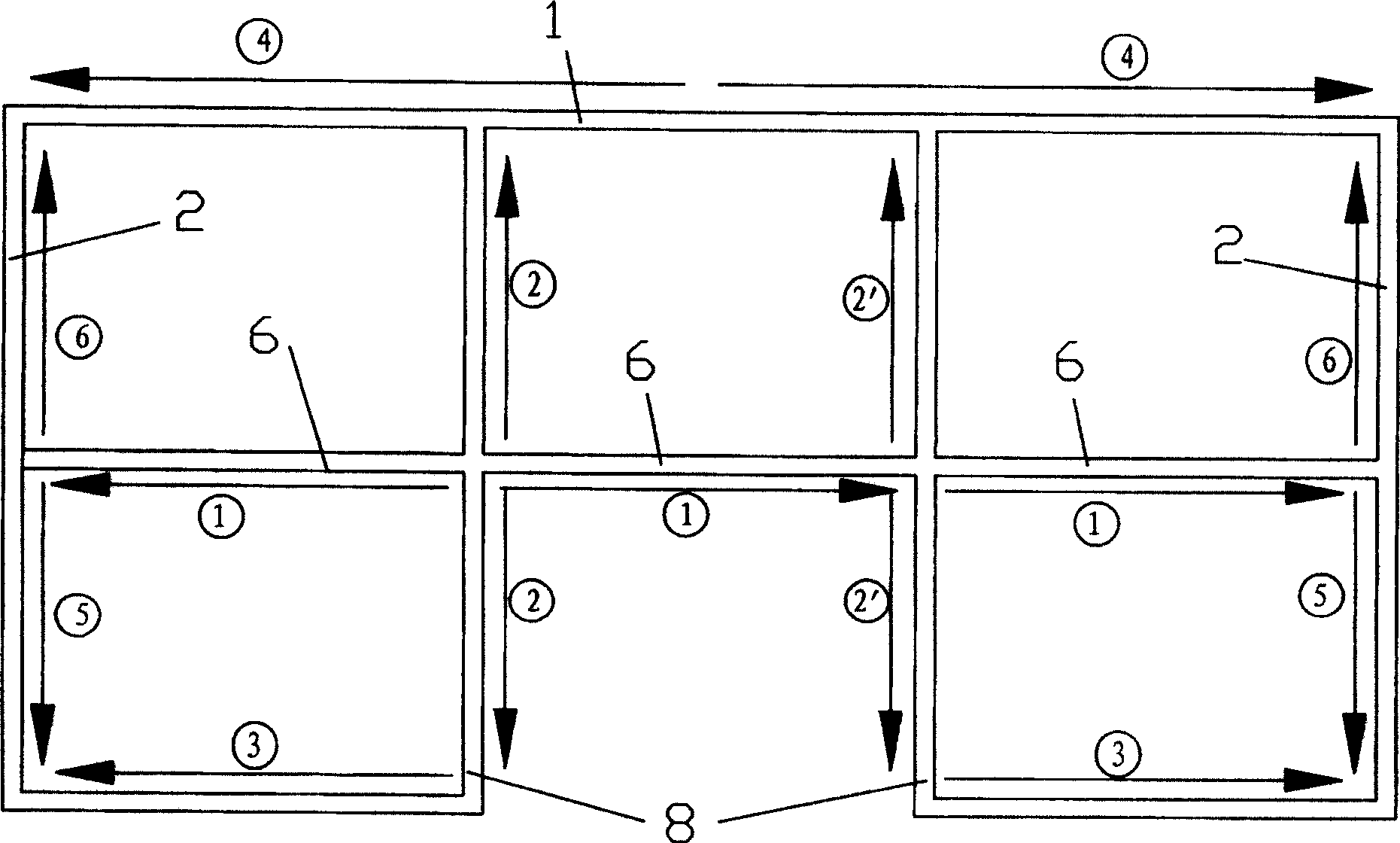

[0012] The drilling platform is used for the exploration of offshore oil / gas resources, and the lifting and position keeping of the platform are realized by the lifting device. The lifting device box body of the present invention is mainly used for supporting and setting the lifting device. Its structure is as figure 1 As shown, it includes a bottom plate 4, a back plate 1 and a panel 5 oppositely arranged on the bottom plate 4, and a sealing plate 2 arranged on both sides of the back plate 1 and the panel 5; Transverse partitions 6 and longitudinal partitions 8 are provided. A wing plate 7 arranged at a certain angle is fixed at the junction between the sealing plate 2 and the panel 5 , and a reinforcing plate 3 is arranged between the wing plate 7 and the sealing plate 2 .

[0013] The present invention is aimed at figure 1 The box body shown provides a convenient welding process method. Before welding, the yield strength of the steel plate is required to reach 460 MPa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com