Split screw pile and welding method thereof

A spiral ground pile and split-type technology, applied in welding equipment, welding accessories, sheet pile walls, etc., can solve the problems of deterioration of welding seam crystallization conditions, poor weld pool formation and metal bonding, and small effective welding area. The effect of reducing processing and production costs, eliminating unfused defects between layers, and increasing effective welding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0038] Hereinafter, the present invention will be further described with reference to the drawings and specific implementations:

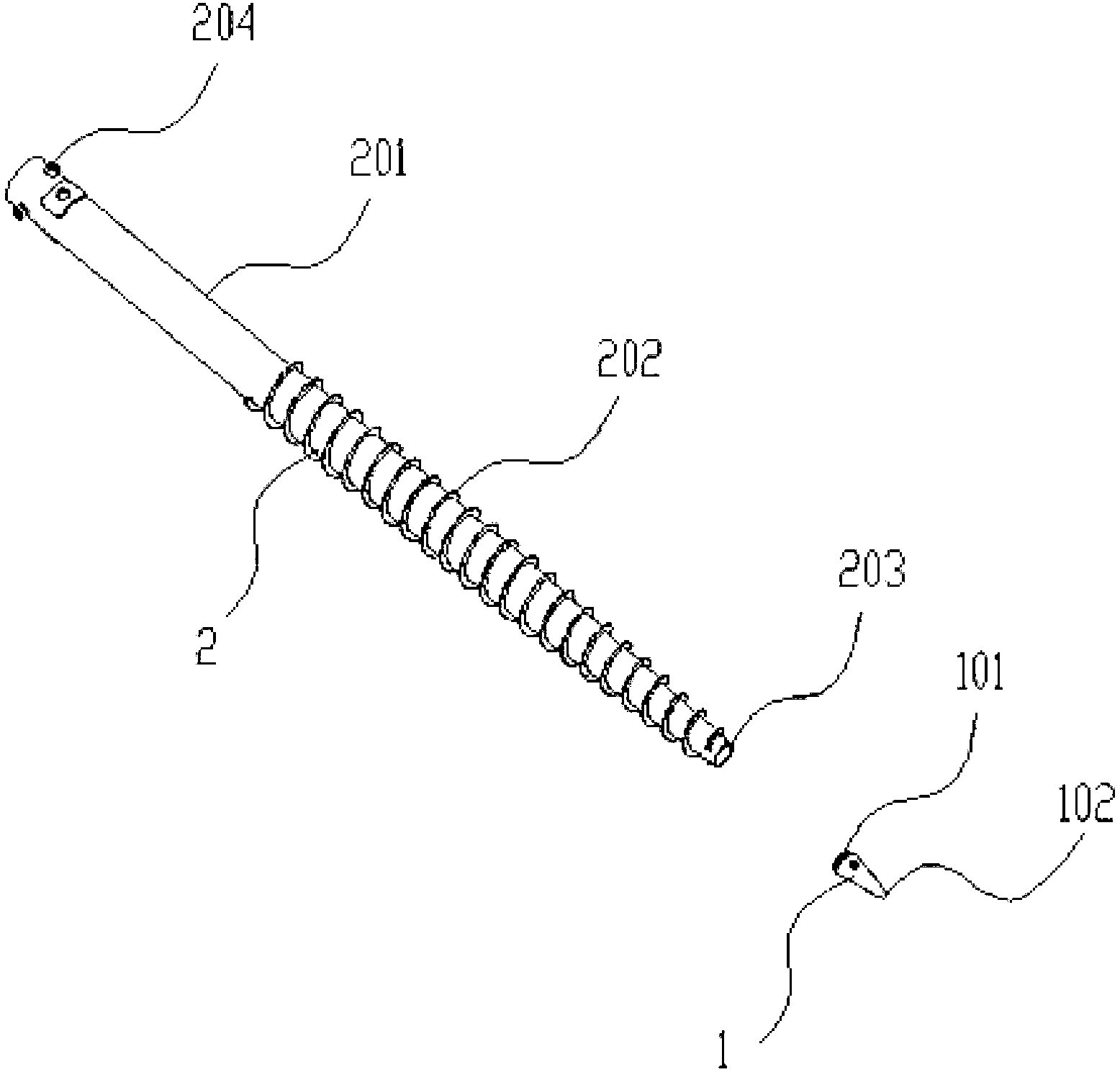

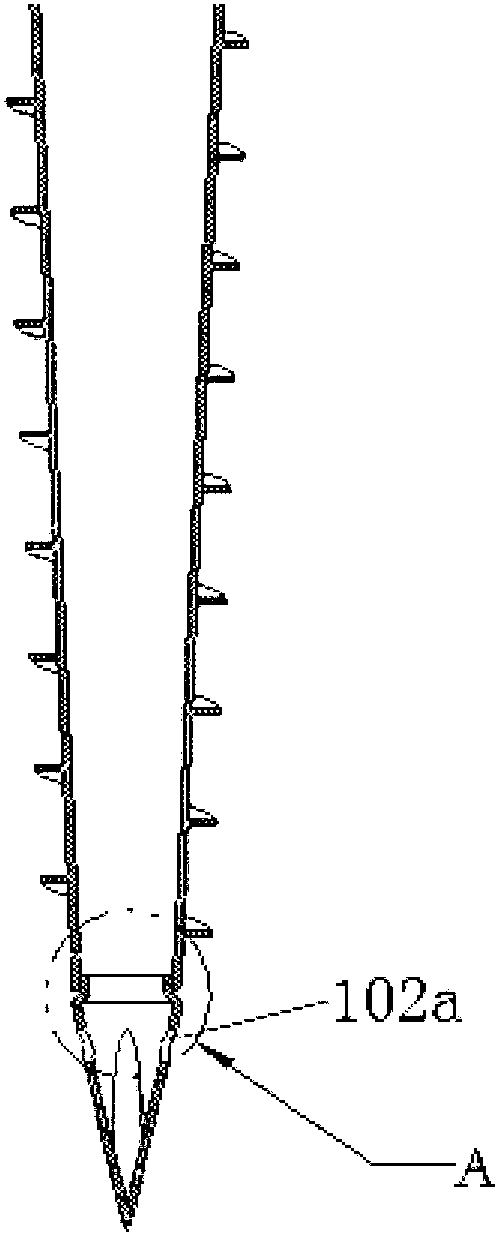

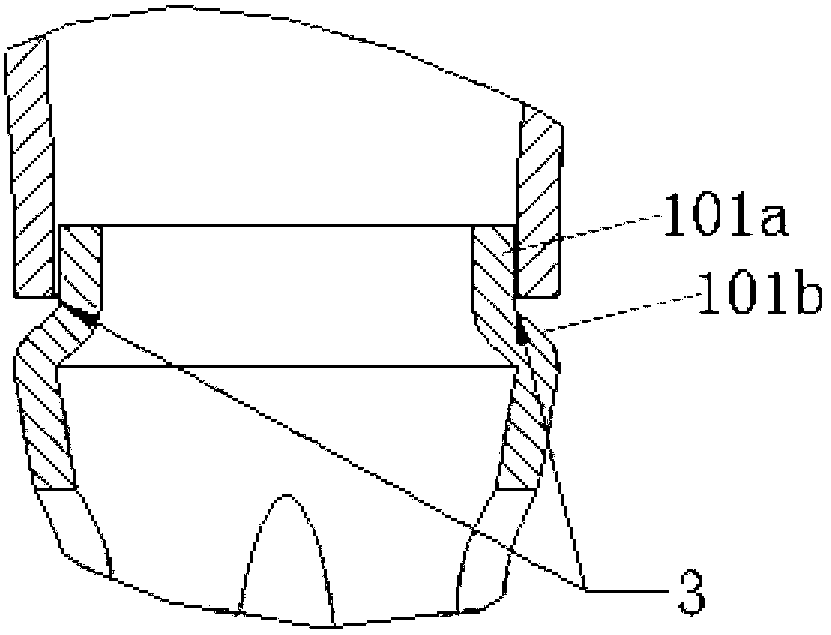

[0039] Reference Figure 1-Figure 3 , The split spiral ground pile described in this embodiment includes a split tubular pile body 2 and a conical ground drilling tip 1. The outer surface of the pipe body 201 of the pile body 2 is sheathed in a spiral belt shape The helical blade 202 of the body; the ground-boring tip 1 includes a tip portion 102 and a truncated cone-shaped tail 101; the truncated cone-shaped tail 101 includes an insertion portion 101a that matches the inner wall of the pile body 2 and a diameter larger than the insertion portion The inclined surface 101b; the insertion portion 101a of the drill tip is inserted into the socket hole of the pile 2, so that the inclined surface 101b of the drill tip 1 and the open end surface 203 of the pile 2 form an annular weld Groove 3, the axial cross-section of the annular welding groove 3 is a ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com