Surfacing method for antiseptic wear-resisting layer of dovetail groove

An anti-corrosion and wear-resistant, dovetail groove technology, applied in the field of surfacing, can solve problems such as difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

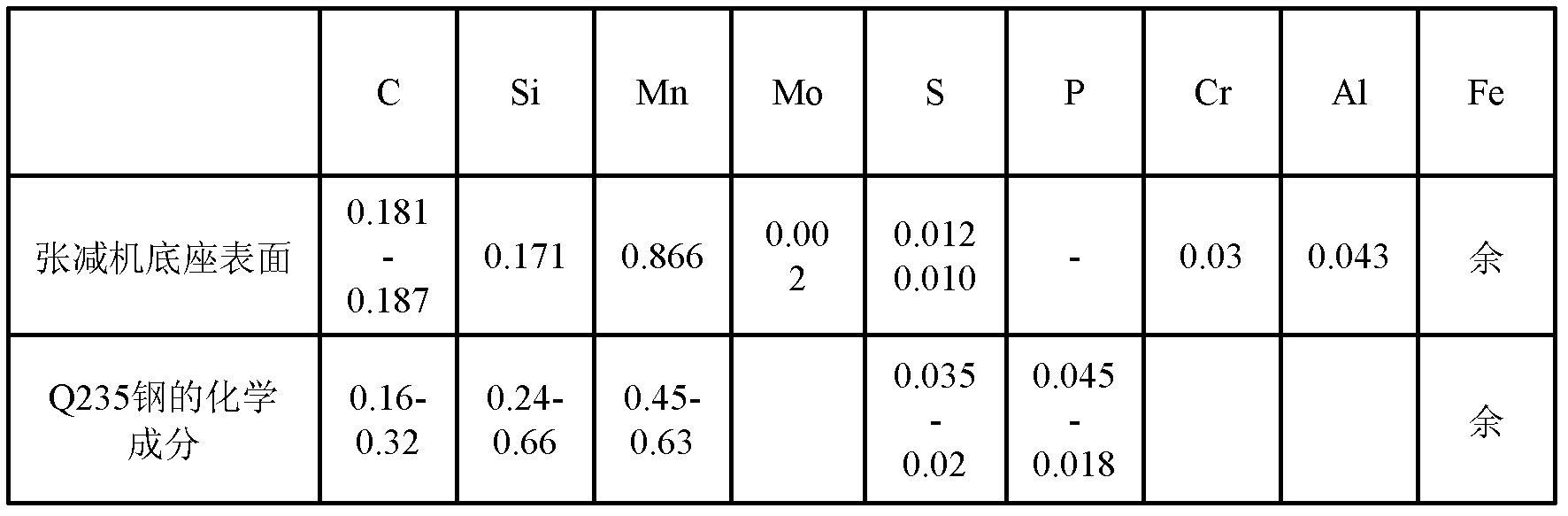

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

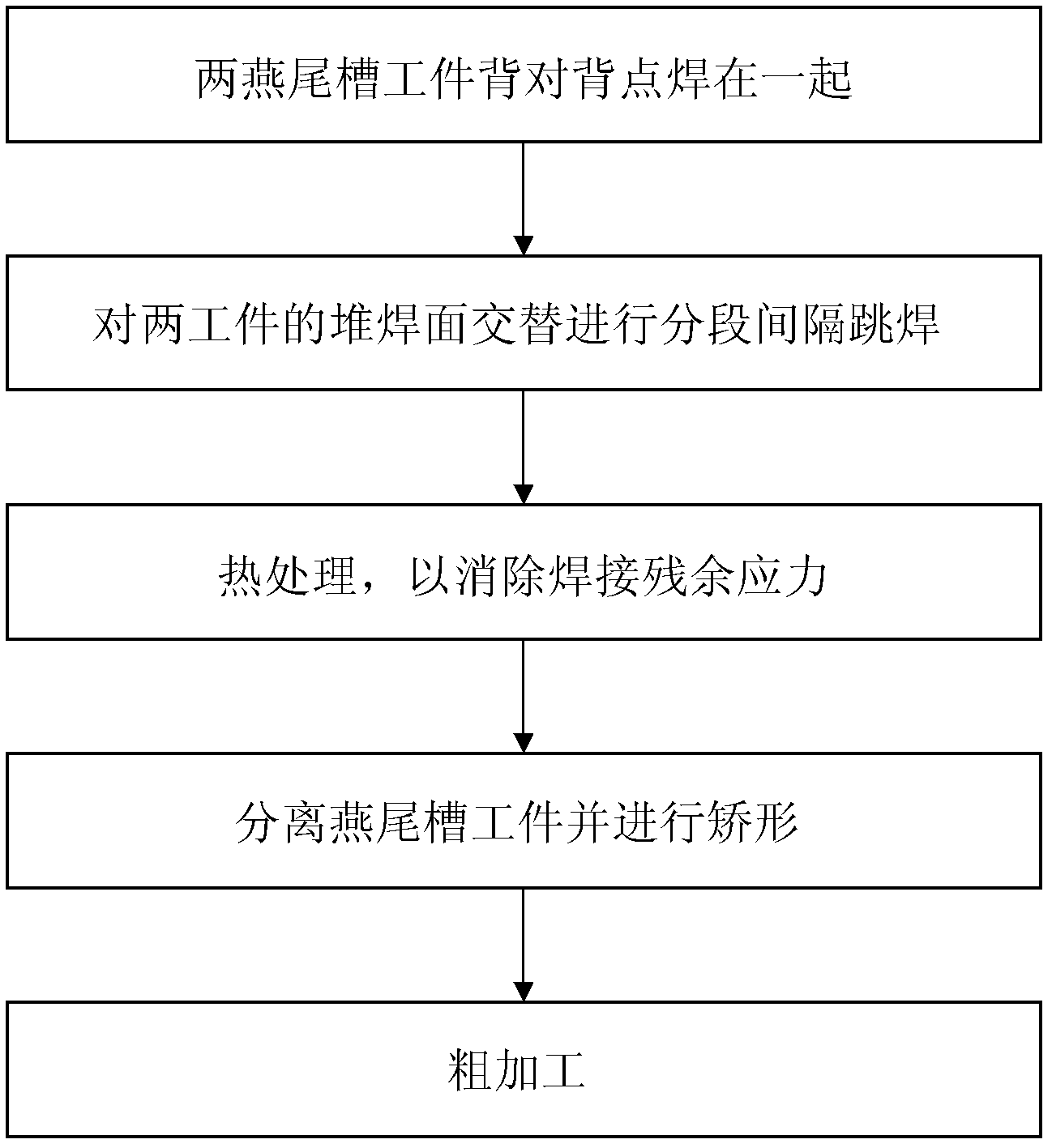

[0032] see figure 2 As shown, the overlay welding method of the dovetail groove anticorrosion wear-resistant layer of the present invention specifically comprises the following steps:

[0033] A. Spot weld two dovetail workpieces back to back to form a symmetrical structure;

[0034] B. Alternately perform segmented interval jump welding on the inclined groove surface and the horizontal groove surface of the upper and lower dovetail groove workpieces;

[0035] C. Perform heat treatment on the dovetail groove workpiece after surfacing to eliminate welding residual stress;

[0036] D. Separate the dovetail groove workpiece welded together at two points, and use a hydraulic press to correct the deformed dovetail groove workpiece;

[0037] E. Rough machining the separated dovetail workpiece.

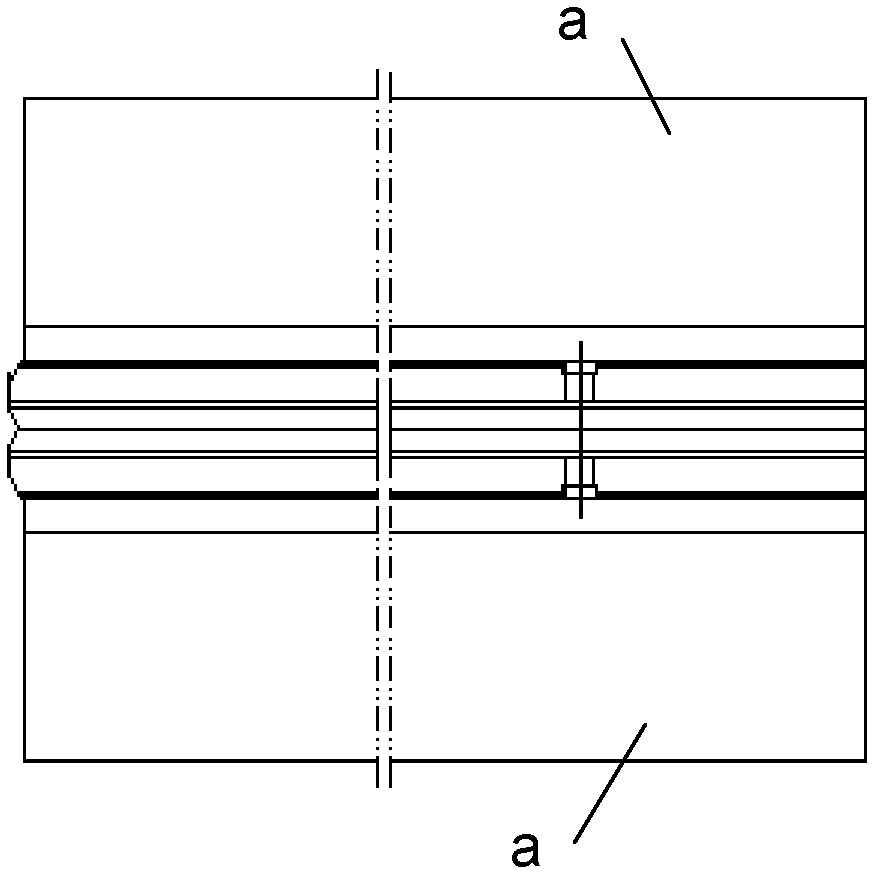

[0038] see image 3 , Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com