Crosslinked starch reinforced composite shear thickening elastomer

A technology of cross-linked starch and reinforced composite, which is applied in the direction of synthetic resin layered products, protective equipment, clothing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1: A cross-linked starch reinforced composite shear thickening glue

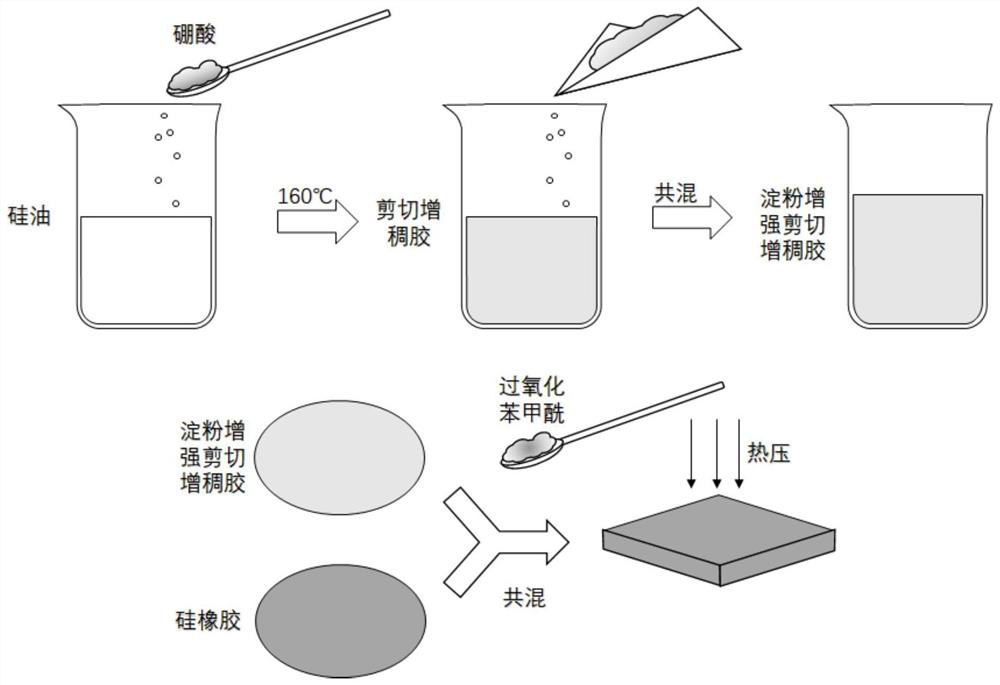

[0054] A kind of preparation method of cross-linked starch reinforced composite shear thickening glue, described preparation method comprises the steps:

[0055] (1) Take 100 parts of dry starch, add 100 parts of deionized water, stir and dissolve to make starch milk. Add 10 parts of 50% glutaraldehyde to the starch milk and stir evenly. Stir mechanically for 5 hours under the condition of heating in a water bath at 40° C. to obtain uniform starch milk. The obtained starch milk is vacuum filtered, washed with cold water for 2 to 3 times, and dried at 50°C to obtain the glutaraldehyde crosslinked starch product.

[0056] (2) Dehydrate boric acid at 160°C for 2 hours, then add 1 part of boric acid to 80 parts of 2000cst polydimethylsiloxane, and mix it mechanically at 160°C for 2 hours to obtain a shear thickening gel ;

[0057] (3) Put glutaraldehyde cross-linked starch and shear thickening...

Embodiment 2

[0065] The method for preparing crosslinked starch with reference to embodiment 1 strengthens composite shear thickening glue, and difference is only, the mass ratio of glutaraldehyde crosslinking starch in embodiment 1, shear thickening glue is adjusted to 2:8,3: 7. 4:6, 5:5, 6:4, other conditions are the same as in Example 1. For the convenience of subsequent comparison, they are numbered as Example 2a, Example 2b, Example 2c, Example 2d, and Example 2e.

[0066] Table 1

[0067]

[0068] The modulus and energy absorption properties of starch-reinforced composite shear-thickening glue were determined by using the stress-strain mode and large oscillation mode of the rheometer. The larger the modulus of the sample, the higher the stress it can get when it is subjected to external force, so as to achieve better protection effect. The larger the area covered by the hysteresis curve, the stronger its energy dissipation capability, and correspondingly, it can dissipate more e...

Embodiment 3

[0071] A kind of preparation method of crosslinked starch reinforced composite shear thickening elastomer, described preparation method comprises the steps:

[0072] (1) Preparation of glutaraldehyde cross-linked starch: Take 100 parts of dry starch, add 100 parts of deionized water, stir and dissolve to make starch milk. Add 10 parts of 50% glutaraldehyde to the starch milk and stir evenly. Stir mechanically for 5 hours under the condition of heating in a water bath at 40° C. to obtain uniform starch milk. The obtained starch milk is vacuum filtered, washed with cold water for 2 to 3 times, and dried at 50°C to obtain the glutaraldehyde crosslinked starch product.

[0073] (2) Preparation of shear thickening glue: dehydrate boric acid at 160°C for 2 hours, then add 1 part of boric acid to 80 parts of 2000cst polydimethylsiloxane, and mix it by mechanical stirring for 3 hours at 160°C , to obtain a shear thickening glue;

[0074] (3) Prepare shear thickening elastomer: the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com