Anti-wrinkle finishing agent for cotton fabrics, and preparation method and application thereof

An anti-wrinkle finishing agent and anti-wrinkle finishing technology, which is applied in the direction of textiles and papermaking, fiber treatment, plant fiber, etc., can solve the problems of fabric strength reduction, poor washability and yellowing of fabrics, and improve washability and cost. low, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

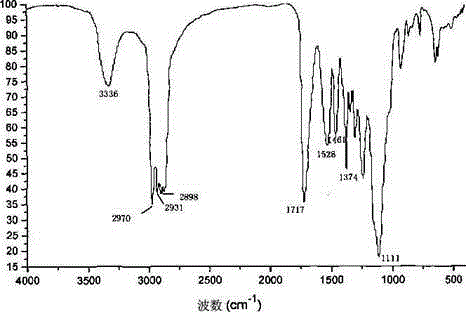

Image

Examples

Embodiment 1

[0029] (1) Preparation of waterborne polyurethane prepolymer:

[0030] At 60°C, add 16.7g isophorone diisocyanate and 0.1g catalyst dibutyltin dilaurate after dehydration of 39g polyether diol (molecular weight 2000) and 3.4g water-soluble chain extension component dimethylol propionic acid , stirred evenly, heated up to 95° C., protected by nitrogen, and reacted for 4 hours to obtain a water-based polyurethane prepolymer.

[0031] (2) Preparation of end-capped waterborne polyurethane:

[0032] At 20°C, 3.2g of capping agent NaHSO 3 0.7g Accelerator Na 2 SO 3 Add 4.5mL ethanol to the above water-based polyurethane prepolymer, then add 3.2mL triethylamine to neutralize, after reacting for 0.5 hours, add 150g deionized water under vigorous stirring to disperse, and after 0.5 hours, sodium bisulfite-capped Clear and stable aqueous polyurethane solution.

[0033] (3) Anti-wrinkle finishing:

[0034] Dip cotton muslin cloth twice in the above finishing solution and roll twic...

Embodiment 2

[0038] (1) Preparation of water-based polyurethane prepolymer: at 60°C, 27.5g polyether diol (molecular weight 1000) and 3.15g water-soluble chain-extending component dimethylol propionic acid were dehydrated and 19.9g isofor was added Ketone diisocyanate and 0.1 g of catalyst dibutyltin dilaurate were stirred evenly, and the temperature was raised to 95° C. under nitrogen protection. After 4 hours of reaction, a water-based polyurethane prepolymer was obtained.

[0039] (2) Preparation of end-capped waterborne polyurethane:

[0040] At 20°C, 4.1g of capping agent NaHSO 3 0.9g Accelerator Na 2 SO 3 Add 4 mL of ethanol to the above water-based polyurethane prepolymer, then add 3.4 mL of triethylamine to neutralize, after 0.5 hours of reaction, add 130 g of deionized water under vigorous stirring to disperse, and after 0.5 hours, sodium bisulfite-capped transparent Stable aqueous polyurethane solution.

[0041] (3) Anti-wrinkle finishing:

[0042] Soak the cotton khaki twic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com