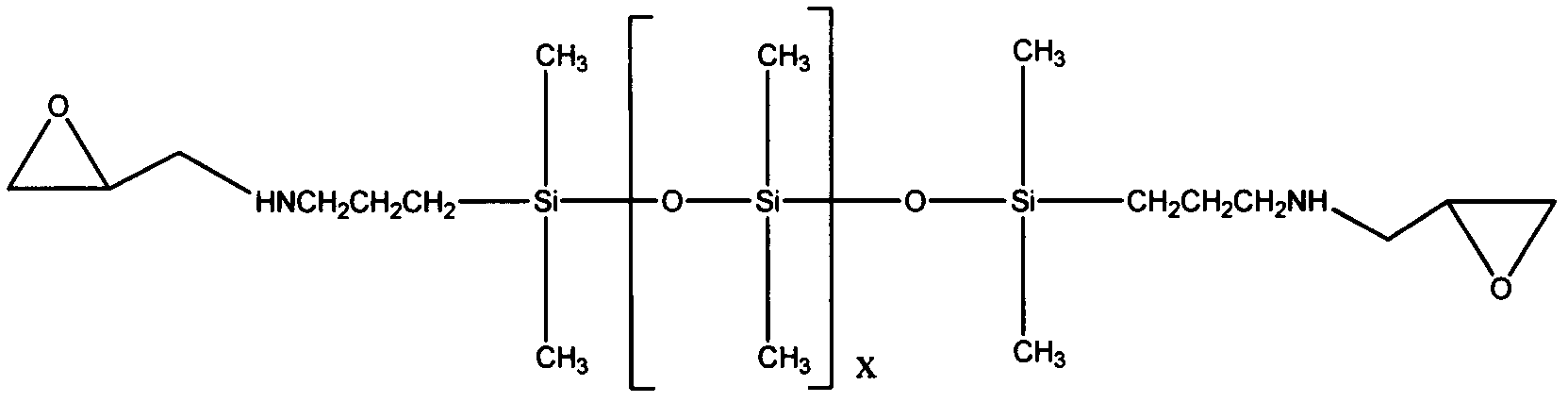

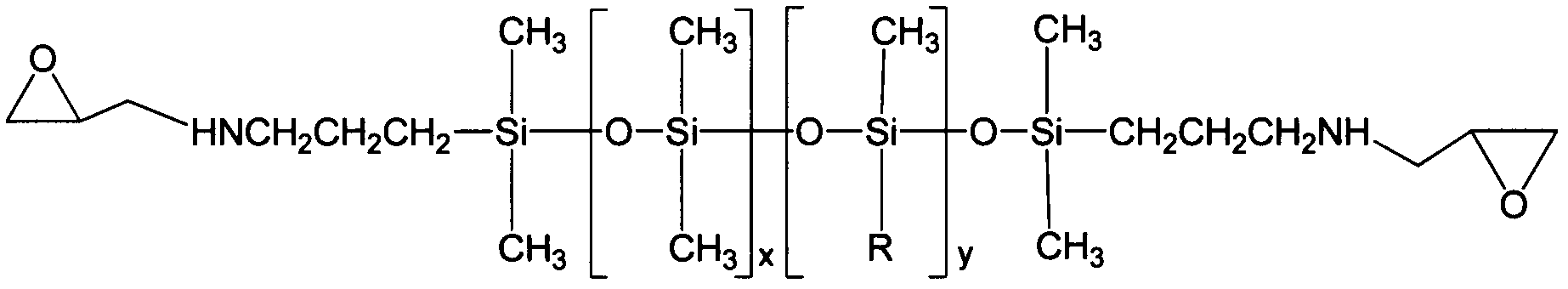

Preparation method of long-chain alkane and epoxy co-modified amino-terminated silicone oil

A technology of long-chain alkane and amino silicone oil, applied in the field of preparation of amino silicone oil, can solve various problems such as unsatisfactory properties, affecting physical properties, color change, etc., to improve the degree of yellowing, increase the waxy feeling and fluffy sense of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

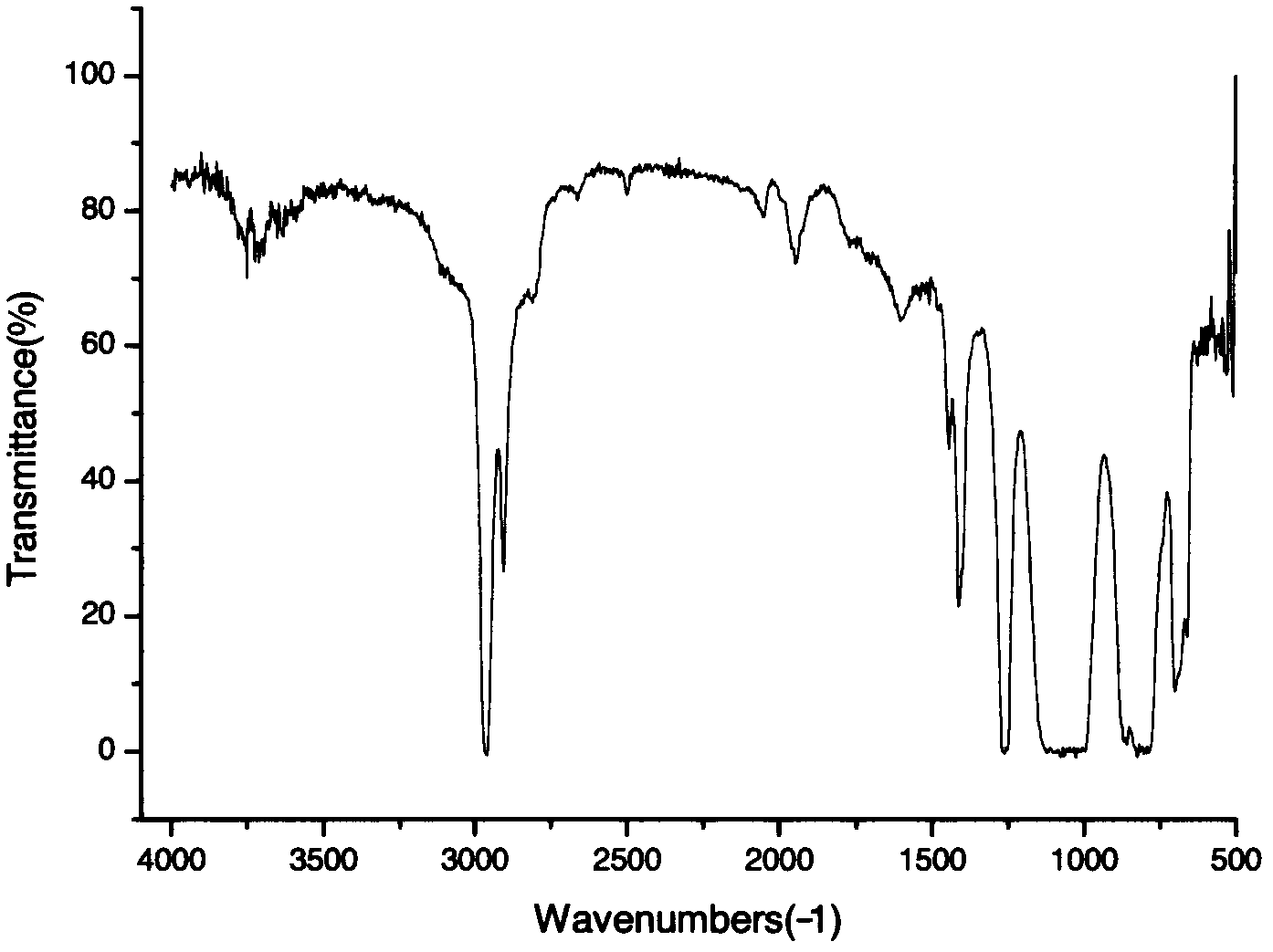

Examples

Embodiment 1

[0031] In a 1000ml four-necked flask equipped with a mechanical stirrer, condenser, thermometer, and nitrogen tube, add 300g octamethylcyclotetrasiloxane and 2.1g 1,3-bis(3-aminopropyl)-1, 1',3,3'-Tetramethyldisiloxane, stir and mix evenly, heat up to 60°C, add 12g of tetramethylammonium hydroxide alkali gum with a mass fraction of 1%, and stir for 0.5 hours, then heat up To 100°C, heat preservation reaction for 8 hours. Rapidly raise the temperature to 150°C to decompose the catalyst for 0.5 hours, then lower the temperature to 80°C, react at a vacuum of 0 MPa for 0.5 hours, and cool down to room temperature to obtain a colorless and transparent long-chain alkane-modified double-ended amino silicone oil.

[0032] 100 g of the obtained long-chain alkane-modified amino silicone oil was dissolved in 70 ml of toluene, and the temperature was raised to 65° C., under nitrogen protection, 1.6 g of epichlorohydrin was added, and the reaction was stirred for 6 hours. Afterwards, the ...

Embodiment 2

[0034] In a 1000ml four-necked flask equipped with a mechanical stirrer, a condenser, a thermometer, and a nitrogen tube, add 300g of octamethylcyclotetrasiloxane, 1g of octaalkylmethyldimethoxysiloxane and 4.5g of 1 , 3-bis(3-aminopropyl)-1,1',3,3'-tetramethyldisiloxane, stir and mix evenly, heat up to 80°C, add potassium hydroxide containing 1% mass fraction 15g of alkali glue was stirred and reacted for 1 hour, then the temperature was raised to 130°C, and the reaction was kept for 6 hours. React for 0.5 hour at a vacuum degree of 0 MPa, and cool down to room temperature to obtain a colorless and transparent long-chain alkane-modified double-ended amino silicone oil.

[0035] 100 g of the obtained long-chain alkane-modified amino-terminated silicone oil was dissolved in 100 ml of xylene, and the temperature was raised to 70° C., under nitrogen protection, 3.4 g of epichlorohydrin was added, and the reaction was stirred for 4 hours. Afterwards, the solvent was evaporated un...

Embodiment 3

[0037] In a 1000ml four-necked flask equipped with a mechanical stirrer, a condenser, a thermometer, and a nitrogen tube, add 300g of octamethylcyclotetrasiloxane, 2.1g of hexadecylmethyldimethoxysiloxane and 6g of 1,3-bis(3-aminopropyl)-1,1′,3,3′-tetramethyldisiloxane, stir and mix evenly, heat up to 70°C, add tetramethyldisiloxane containing 1% mass fraction 18 g of base ammonium hydroxide alkali gel and stirred for 0.5 hours, then heated up to 110° C., and kept for 7 hours. Rapidly raise the temperature to 150°C to decompose the catalyst for 0.5 hours, then lower the temperature to 80°C, react for 1.5 hours under a vacuum of 0 MPa, and cool down to room temperature to obtain a colorless and transparent long-chain alkane-modified double-ended amino silicone oil.

[0038] 100 g of the obtained long-chain alkane-modified amino silicone oil was dissolved in 60 ml of petroleum ether, and the temperature was raised to 80° C., under nitrogen protection, 4.5 g of epichlorohydrin wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com