Intermediate film for laminated glass, laminated glass using the same, and method for production of the laminated glass

A technology of laminated glass and interlayer film, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of transparency, reduced adhesion, insufficient moisture resistance, insufficient transparency, etc. , achieve the effect of improving transparency and improving yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0149] PVB and EVA sheets (thickness: 400 μm) were obtained by calendering using the following formulations as raw materials. In addition, the kneading of the compound was performed at 80° C. for 15 minutes, and the temperature of the calender rolls was 80° C., and the processing speed was 5 m / min.

[0150] (PVB sheet formation formulation (parts by mass))

[0151] PVB resin (degree of acetalization 66 mol%): 100

[0152] Plasticizer (triethylene glycol-bis(2-ethylbutyrate)): 33

[0153] UV absorber (2,2'-dihydroxy-4,4'-dimethoxybenzophenone): 0.15

[0154] (Formulation for EVA sheet formation (parts by mass))

[0155] EVA resin (vinyl acetate content 26% by weight): 100

[0156] Crosslinking agent (1,1-bis(tert-butylperoxy)3,3,5-trimethylcyclohexane): 2.0

[0157] Silane coupling agent (γ-methacryloxypropyltrimethoxysilane): 0.5

[0158] Cross-linking aid (triallyl isocyanurate): 2.0

[0159] UV absorber (2,2'-dihydroxy-4,4'-dimethoxybenzophenone): 0.15

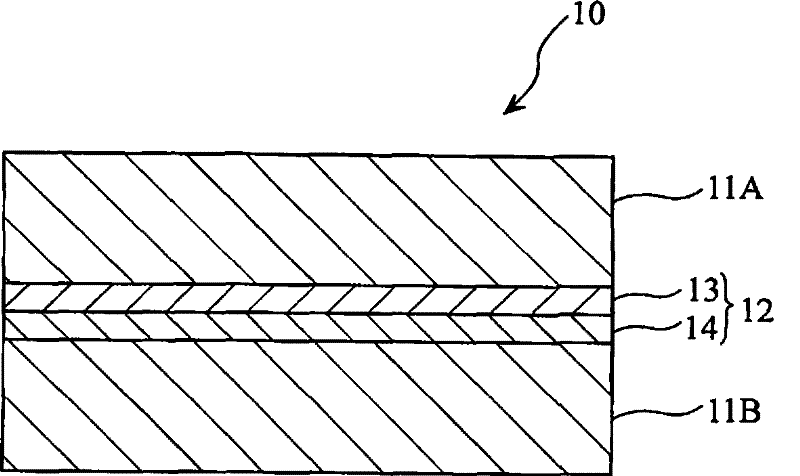

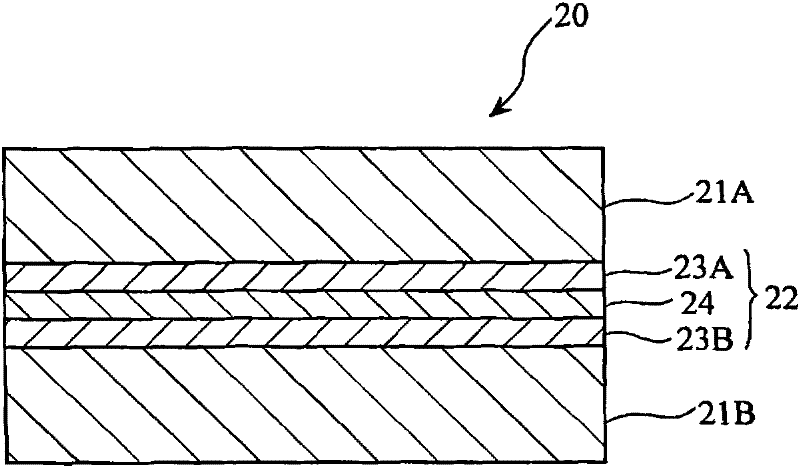

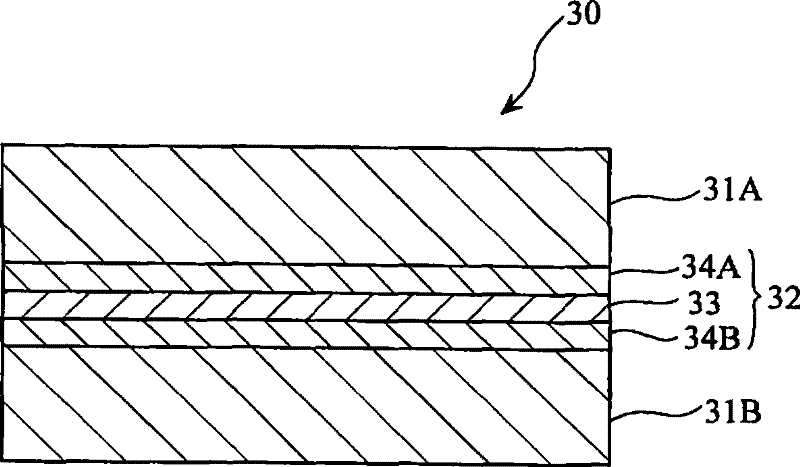

[0160] Two s...

reference example 1

[0163] A laminated glass was produced in the same manner as in Example 1, except that 0.001 parts by mass of magnesium octanoate (adhesion modifier) was added to the formulation for PVB sheet formation.

reference example 2

[0165] In the formula for EVA sheet formation, as a UV absorber, an equivalent amount of 2-(3'-tert-butyl-2'-hydroxyl-5'-methylphenyl)-5-chlorobenzotriazole is used instead A laminated glass was produced in the same manner as in Example 1 except for 2,2'-dihydroxy-4,4'-dimethoxybenzophenone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com