Silicone rubber masterbatch, silicone rubber and preparation method of silicone rubber

A silicone rubber and masterbatch technology, applied in catheters and other directions, can solve the problems of difficulty in endotracheal intubation and the operator being caught off guard, and achieve the effects of improving physical properties, optimizing the production of extruded bubbles and particles, and improving processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

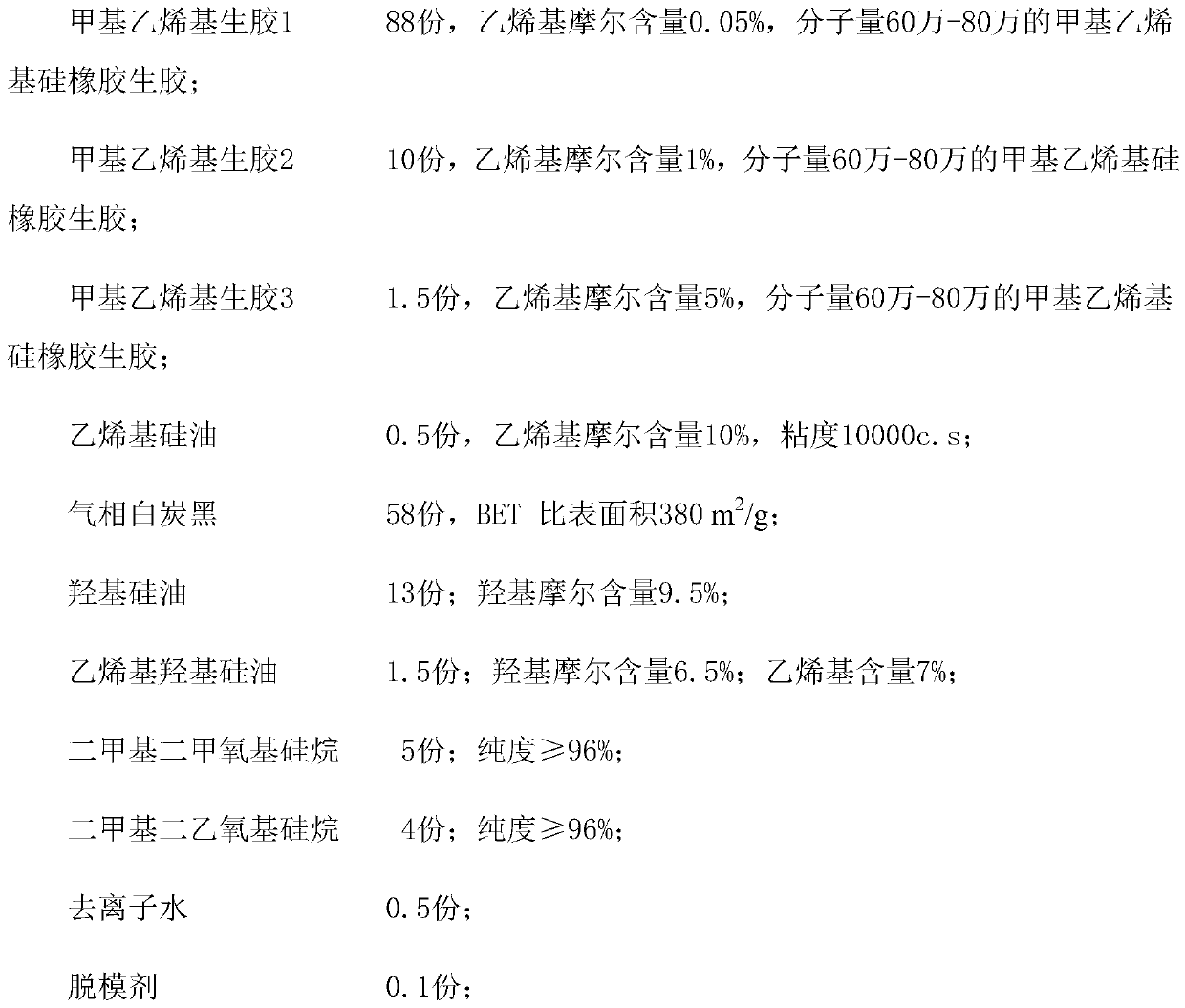

[0070] A silicone rubber used to meet the requirements of medical laryngeal mask tubes, the components in parts by weight of the rubber material are as follows:

[0071] Masterbatch

[0072]

[0073] secondary cooling

[0074] (1) Glue A:

[0075] Masterbatch: 100 parts;

[0076] 2 parts of highly active platinum complex catalyst (platinum content is 15000ppm);

[0077] (2) B glue:

[0078] Masterbatch: 100 parts;

[0079] Hydrogen-containing silicone oil additive 1 (the content of the total hydrogen content is 70%, the hydrogen-containing type is 1.0%, and the kinematic viscosity is 30cs) 3 parts;

[0080] Hydrogen-containing silicone oil additive 2 (the total hydrogen content is 70%, the type of hydrogen content is 0.5%, and the kinematic viscosity is 35cs) 1 part;

[0081] Inhibitor auxiliary (ethynyl cyclohexanol accounts for 0.1% of the total weight of the inhibitor auxiliary, dodecynol accounts for 0.1% of the total weight of the inhibitor auxiliary) 0.5 parts; ...

Embodiment 2

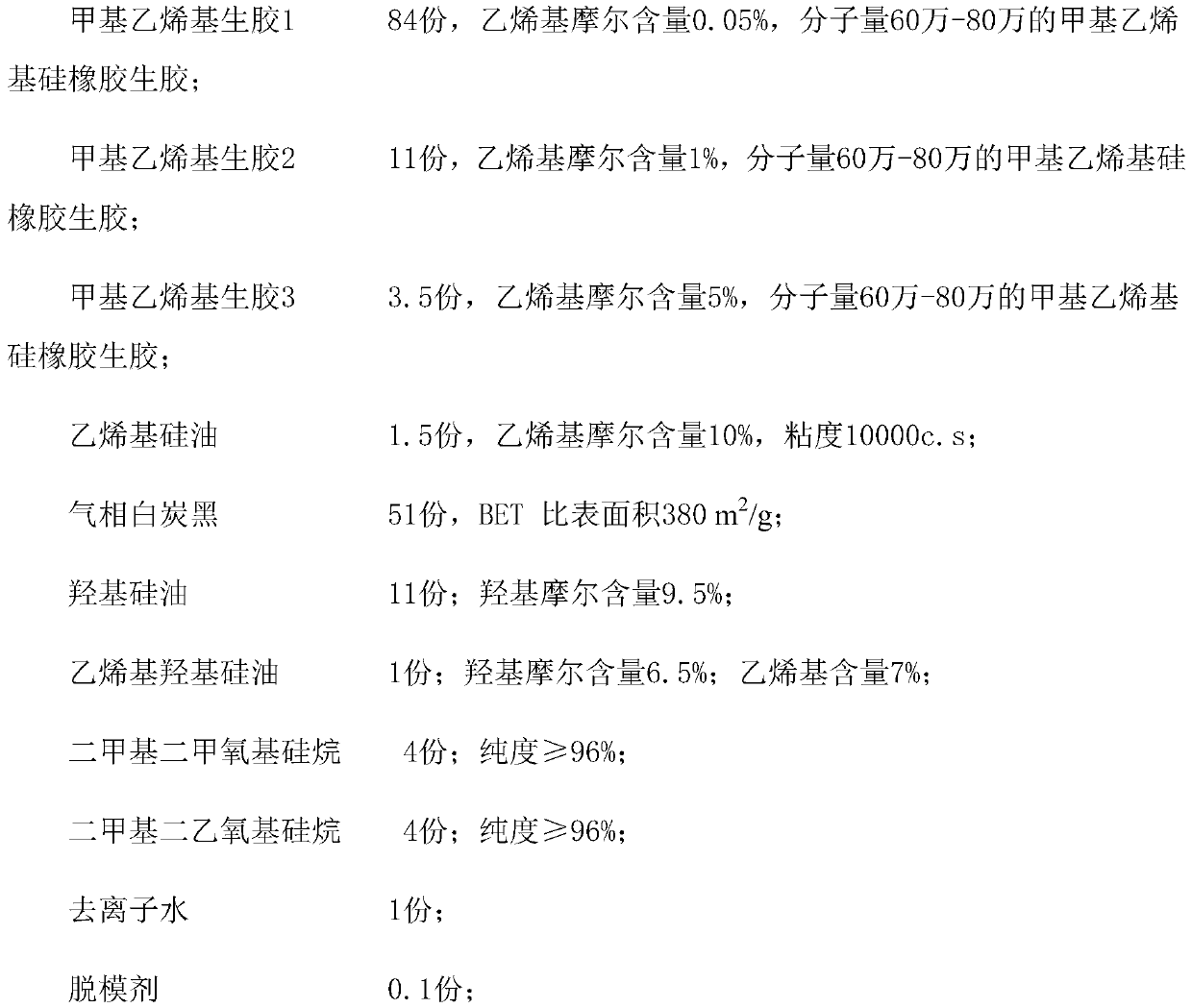

[0092] A silicone rubber used to meet the requirements of medical laryngeal mask tubes, the components in parts by weight of the rubber material are as follows:

[0093] Masterbatch

[0094]

[0095] secondary cooling

[0096] (1) Glue A:

[0097] Masterbatch: 100 parts;

[0098] 2.5 parts of highly active platinum complex catalyst (platinum content is 5000-20000ppm);

[0099] (2) B glue:

[0100] Masterbatch: 100 parts;

[0101] Hydrogen-containing silicone oil additive 1 (70% of total hydrogen content, 1.0% of hydrogen-containing species, kinematic viscosity of 30cs) 4.5 parts;

[0102] Hydrogen-containing silicone oil additive 2 (70% of total hydrogen content, 0.5% of hydrogen content, kinematic viscosity of 35cs) 1.5 parts;

[0103] Inhibitor auxiliary (ethynyl cyclohexanol accounts for 0.1% of the total weight of the inhibitor auxiliary, dodecynol accounts for 0.1% of the total weight of the inhibitor auxiliary) 0.5 parts;

[0104] Put the raw materials used for...

Embodiment 3

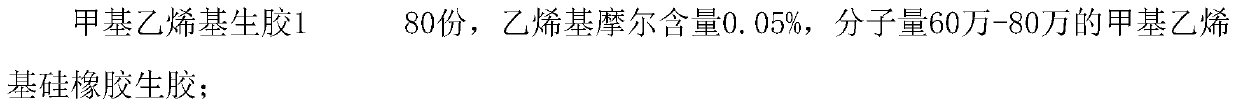

[0114] A silicone rubber used to meet the requirements of medical laryngeal mask tubes, the components in parts by weight of the rubber material are as follows:

[0115] Masterbatch

[0116]

[0117]

[0118] secondary cooling

[0119] (1) Glue A:

[0120] Masterbatch: 100 parts;

[0121] 2.5 parts of highly active platinum complex catalyst (platinum content is 5000-20000ppm);

[0122] (2) B glue:

[0123] Masterbatch: 100 parts;

[0124] Hydrogen-containing silicone oil additive 1 (the content of the total hydrogen content is 70%, the hydrogen-containing type is 1.0%, and the kinematic viscosity is 30cs) 4 parts;

[0125] Hydrogen-containing silicone oil additive 2 (the total hydrogen content is 70%, the type of hydrogen content is 0.5%, and the kinematic viscosity is 35cs) 1 part;

[0126] Inhibitor auxiliary (ethynyl cyclohexanol accounts for 0.15% of the total weight of the inhibitor auxiliary, dodecynol accounts for 0.1% of the total weight of the inhibitor au...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com