Rapid start-up method of hydrocracking catalyst

A hydrocracking and catalyst technology, which is used in hydrocarbon oil cracking, petroleum industry, etc., can solve the problems of difficult control and control, influence of catalyst activity, waste of floor space, etc., to reduce operating fluctuations and operating risks, and accelerate initial activity. The effect of stabilizing the process and stabilizing the catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

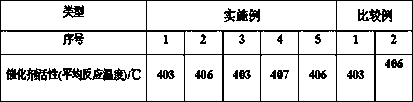

Embodiment 1

[0035] Start the operation according to the start-up process of the conventional hydrocracking unit, control the reactor inlet temperature at 160°C, introduce low-nitrogen oil into the reaction system, raise the reactor inlet temperature to 180°C, and inject vulcanizing agent into the reaction system. After the hydrogen sulfide concentration in the circulating hydrogen reaches 0.1v%, the reactor inlet temperature is increased to 220°C, and the constant temperature sulfuration is carried out for at least 8 hours. Then raise the temperature to 270°C to introduce raw material oil and change it to a one-pass process to continue vulcanization. The temperature rises to 320°C at a rate of 8°C / hour, and the vulcanization ends after 4 hours of constant temperature. Then first raise the reaction temperature to 355° C., adjust the temperature, control the conversion rate to be constant at 35%, and keep it stable for 2 days. After the resurrection process is over, adjust the process condi...

Embodiment 2

[0037] Start the operation according to the start-up process of the conventional hydrocracking unit, control the reactor inlet temperature at 160°C, introduce low-nitrogen oil into the reaction system, raise the reactor inlet temperature to 180°C, and inject vulcanizing agent into the reaction system. After the concentration of hydrogen sulfide in the circulating hydrogen reaches 0.1v%, the inlet temperature of the reactor is raised to 240°C, and the constant temperature sulfuration is carried out for at least 8 hours. Then raise the temperature to 280°C to introduce raw material oil and change it to a one-pass process to continue vulcanization. The temperature rises to 330°C at a rate of 8°C / hour, and the vulcanization ends after 4 hours of constant temperature. Then first increase the reaction temperature to 365°C, adjust the temperature, control the conversion rate to be constant at 35%, and stabilize for 1 day. After the resurrection process is over, adjust the process con...

Embodiment 3

[0039] Start the operation according to the start-up process of the conventional hydrocracking unit, control the reactor inlet temperature at 160°C, introduce low-nitrogen oil into the reaction system, raise the reactor inlet temperature to 180°C, and inject vulcanizing agent into the reaction system. After the hydrogen sulfide concentration in the circulating hydrogen reaches 0.1v%, the reactor inlet temperature is increased to 220°C, and the constant temperature sulfuration is carried out for at least 8 hours. Then raise the temperature to 270°C to introduce raw material oil and change it to a one-pass process to continue vulcanization. The temperature rises to 320°C at a rate of 8°C / hour, and the vulcanization ends after 8 hours of constant temperature. Then first raise the reaction temperature to 360° C., adjust the temperature, control the conversion rate to be constant at 40%, and keep it stable for 2 days. After the resurrection process is over, adjust the process condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com