Patents

Literature

41results about How to "Suitable process conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

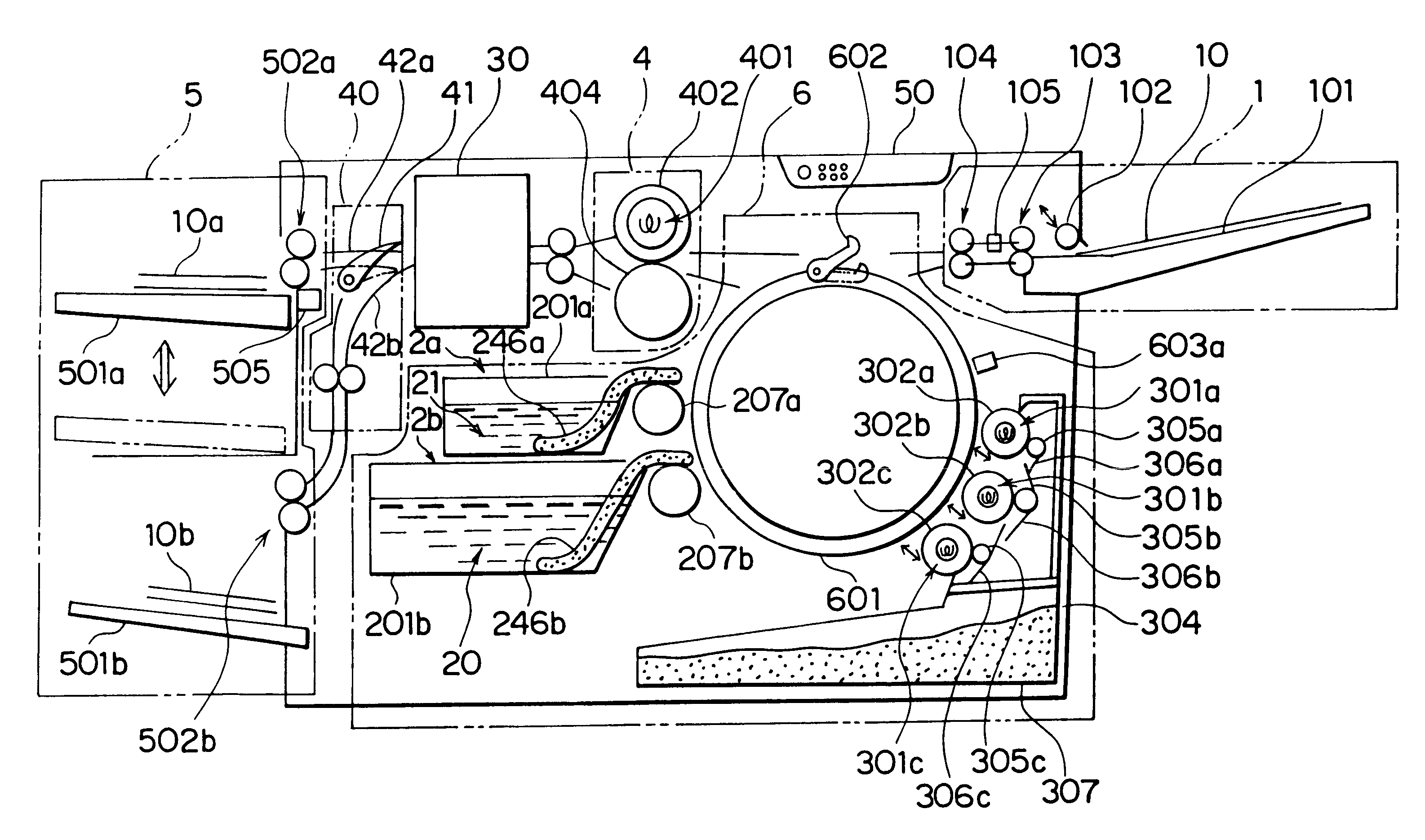

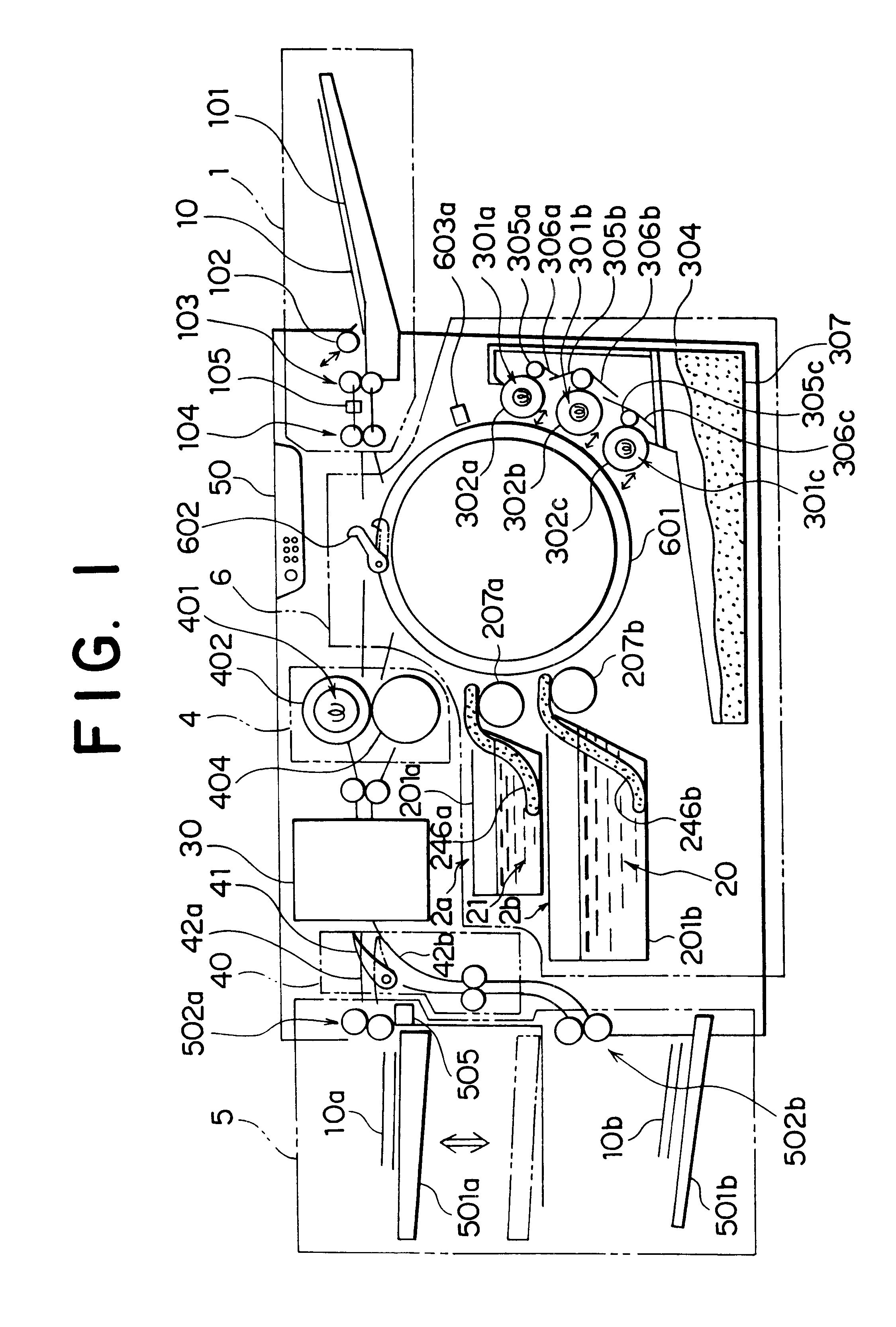

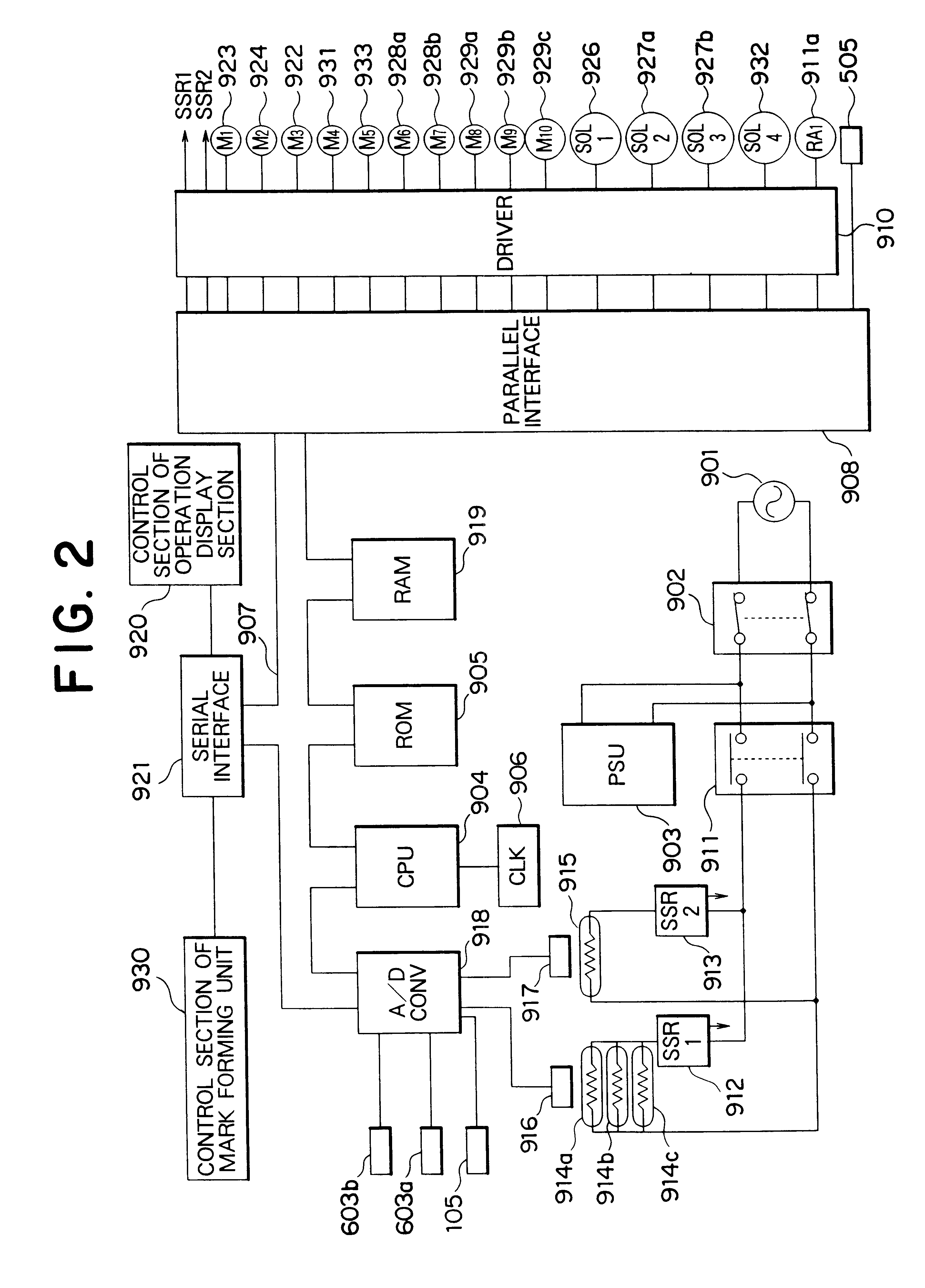

Method and apparatus for removing image forming substance from image holding member forming processing situation mark

InactiveUSRE37645E1Hysteresis of the image holding memberSuitable process conditionsElectrographic process apparatusPrinting after-treatmentForm processingForms processing

In a method and an apparatus for removing an image forming substance such as toner from an image holding member such as a sheet of transfer paper, an unstabilizing agent is provided to the image holding member. An attaching state between the image forming substance and the image holding member stably attaching the image forming substance on a surface thereof is changed to an unstable state by the unstabilizing agent. The image forming substance is separated and removed from the image holding member by making a separating member come in close contact with the image forming substance on the image holding member having the provided unstabilizing agent. A processing situation mark showing a processing situation of removal of the image forming substance is formed in the image holding member. The processing situation mark can be removed from the image holding member by the image forming substance removing processing.

Owner:RICOH KK

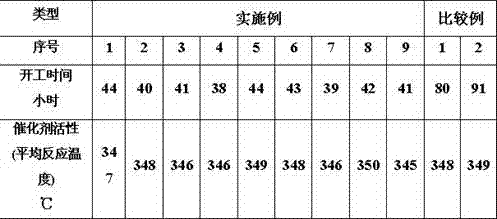

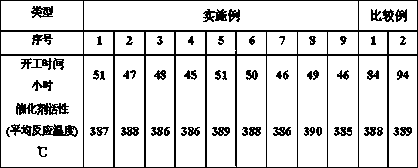

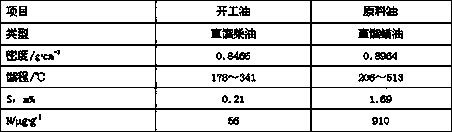

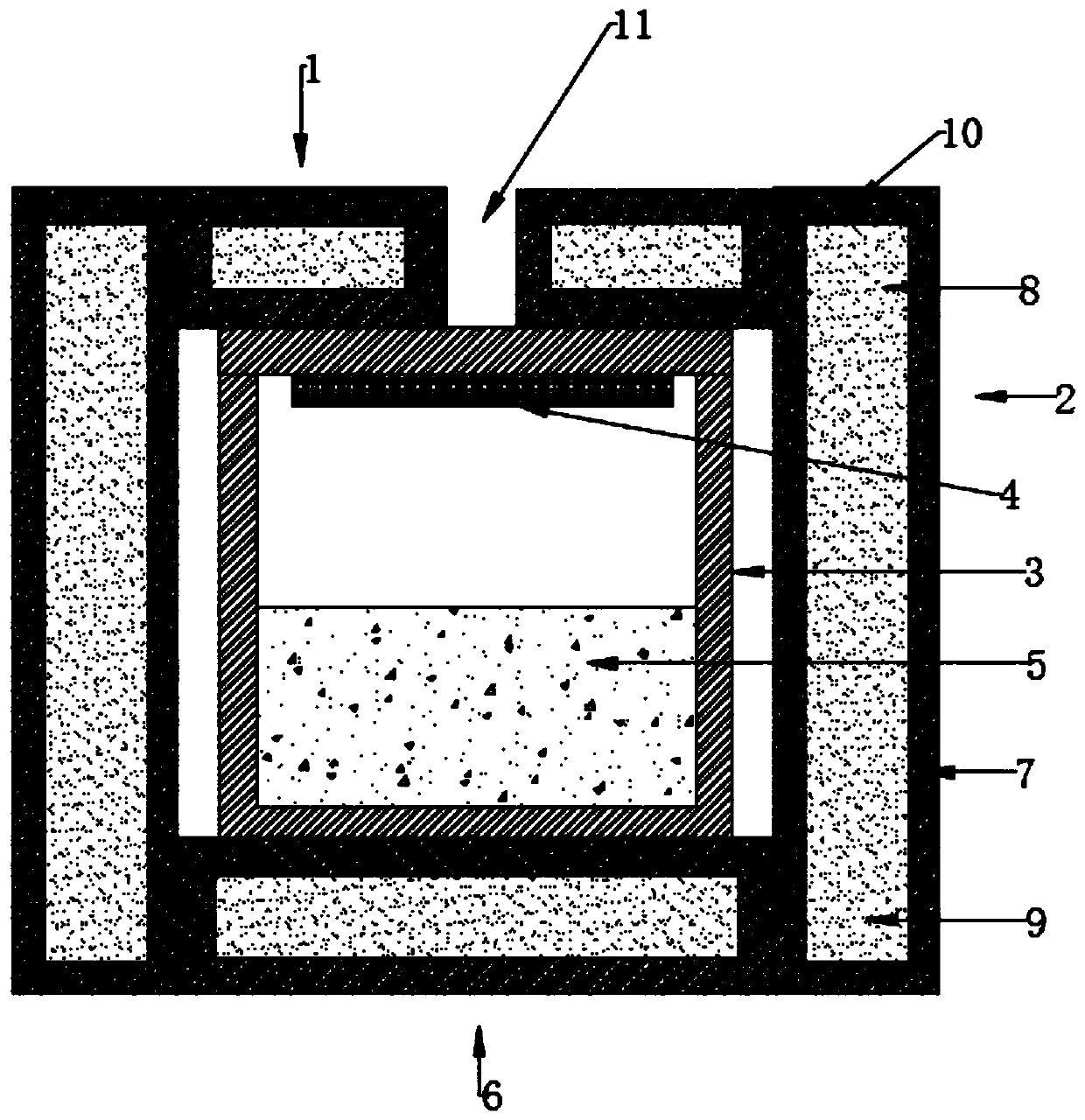

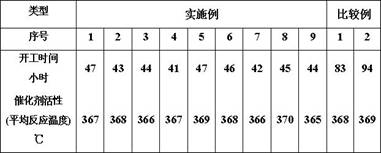

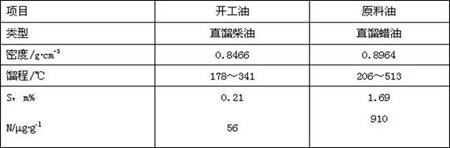

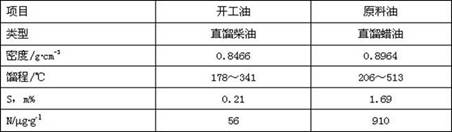

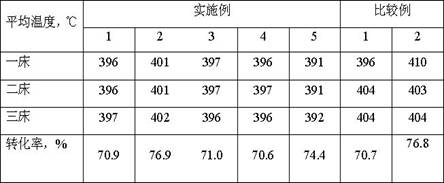

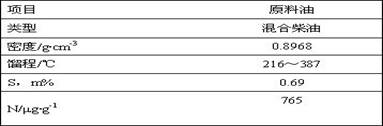

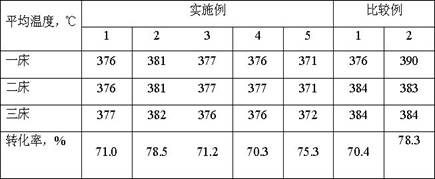

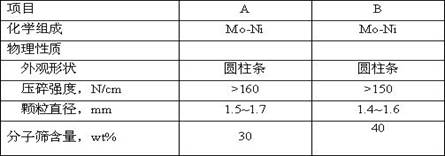

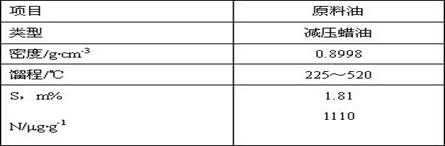

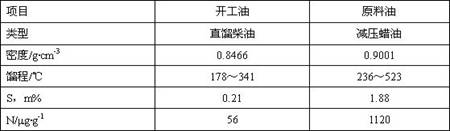

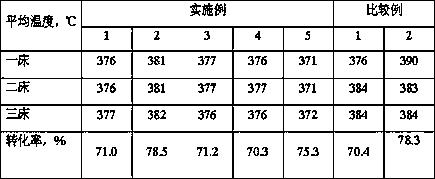

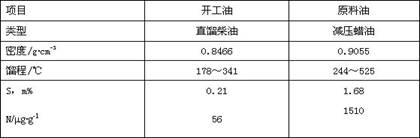

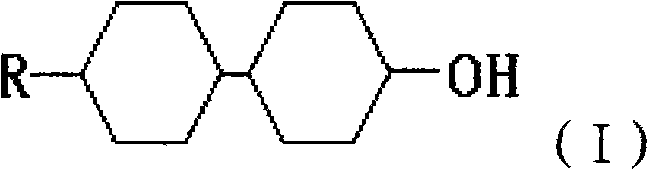

Hydrocracking startup method

ActiveCN107446616AIntensified vulcanization process inside the extenderHigh activityCatalyst protectionMolecular sieve catalystsHydrogenLow nitrogen

The invention discloses a hydrocracking startup method. The hydrocracking startup method comprises the following steps: introducing low-nitrogen startup oil, hydrogen and a sulfurizing reagent into a hydrocracking unit; then carrying out sulfuration on a hydrocracking catalyst at a constant temperature of 220 to 260 DEG C; after the content of hydrogen sulfide in to-be-cycled hydrogen reaches 3000 to 5000 ppm, reducing the adding rate of the sulfurizing reagent and increasing the bed temperature of the hydrocracking catalyst; when the bed temperature of the hydrocracking catalyst reaches 310 to 330 DEG C, increasing the adding rate of the sulfurizing reagent; and continuing constant-temperature sulfuration, then allowing the temperature to rise to 340 to 350 DEG C and introducing raw oil for a reaction, wherein the amount of the hydrocracking catalyst is 0.5 to 8% by weight. The method provided by the invention is short in time for startup, raw material switching and entry into a stable production state, avoids the consumption of a passivating agent and potential hazards during ammonia injection in the startup process, reduces energy consumption, and decreases pollution of the passivating agent to environment and harm of the passivating agent to human beings.

Owner:CHINA PETROLEUM & CHEM CORP +1

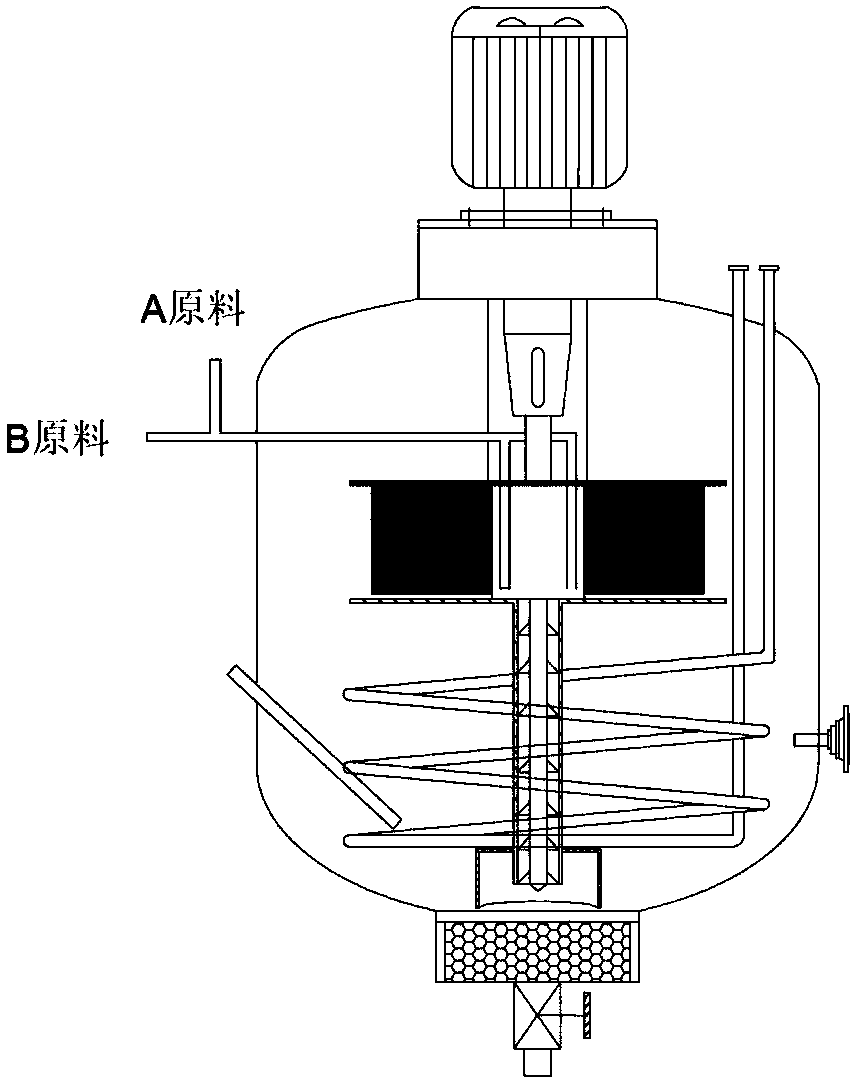

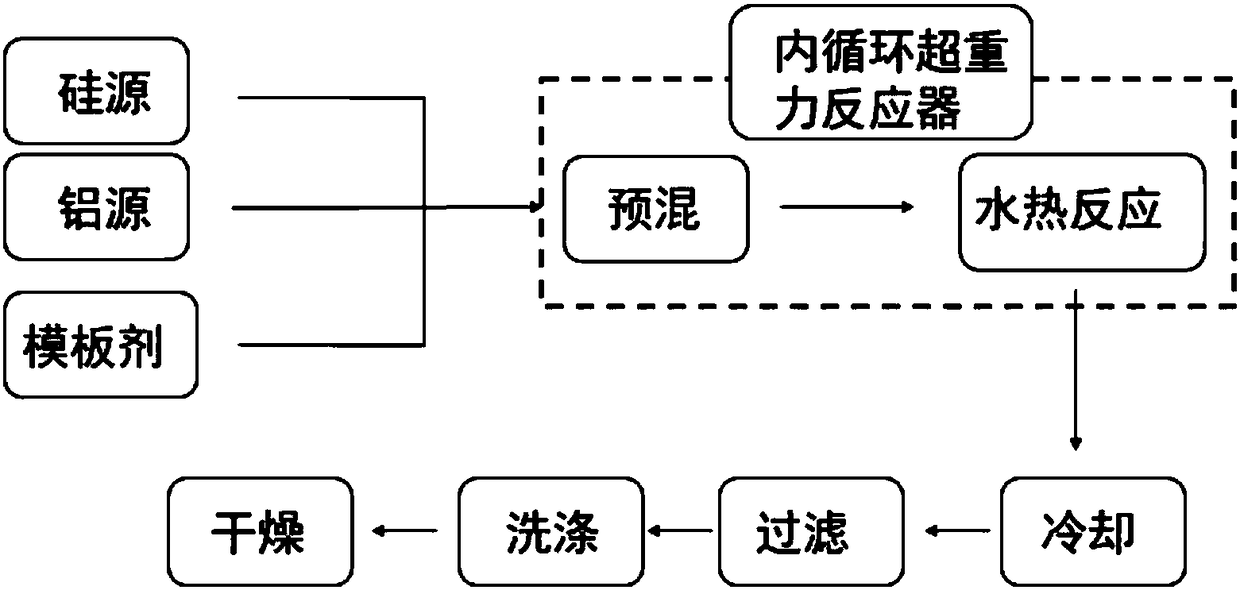

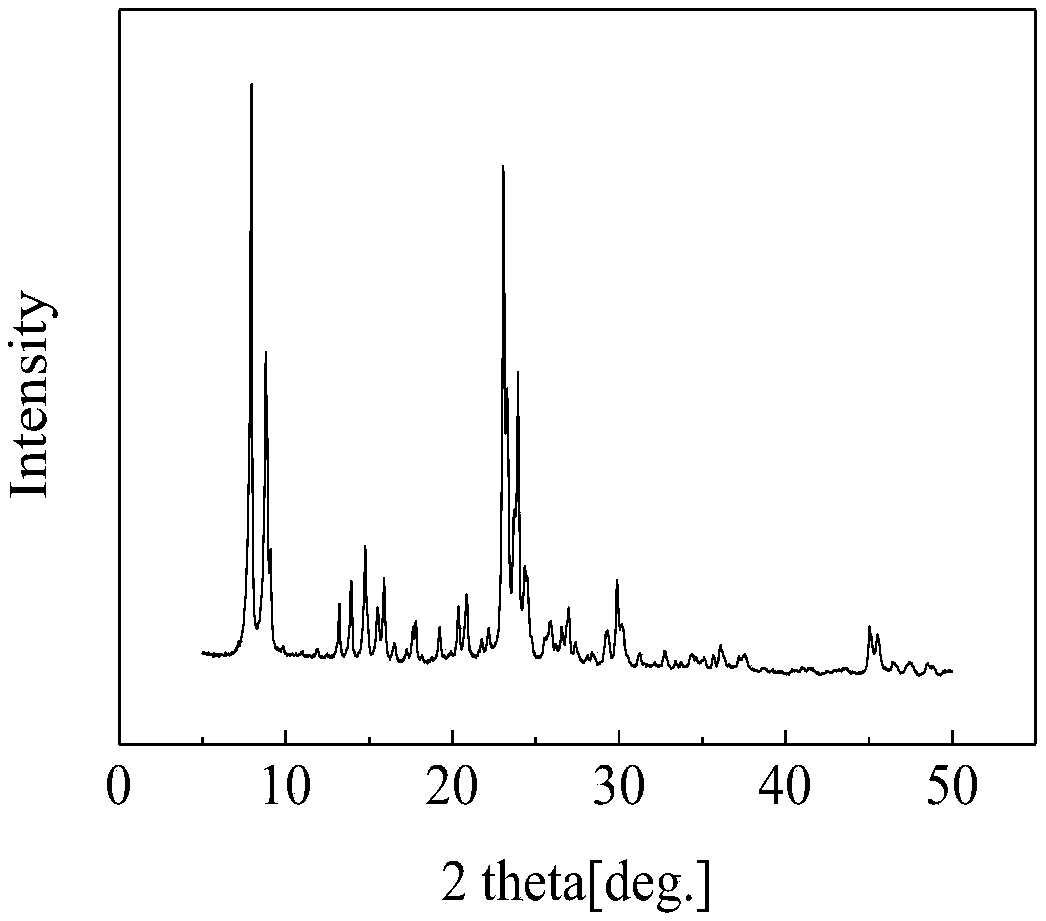

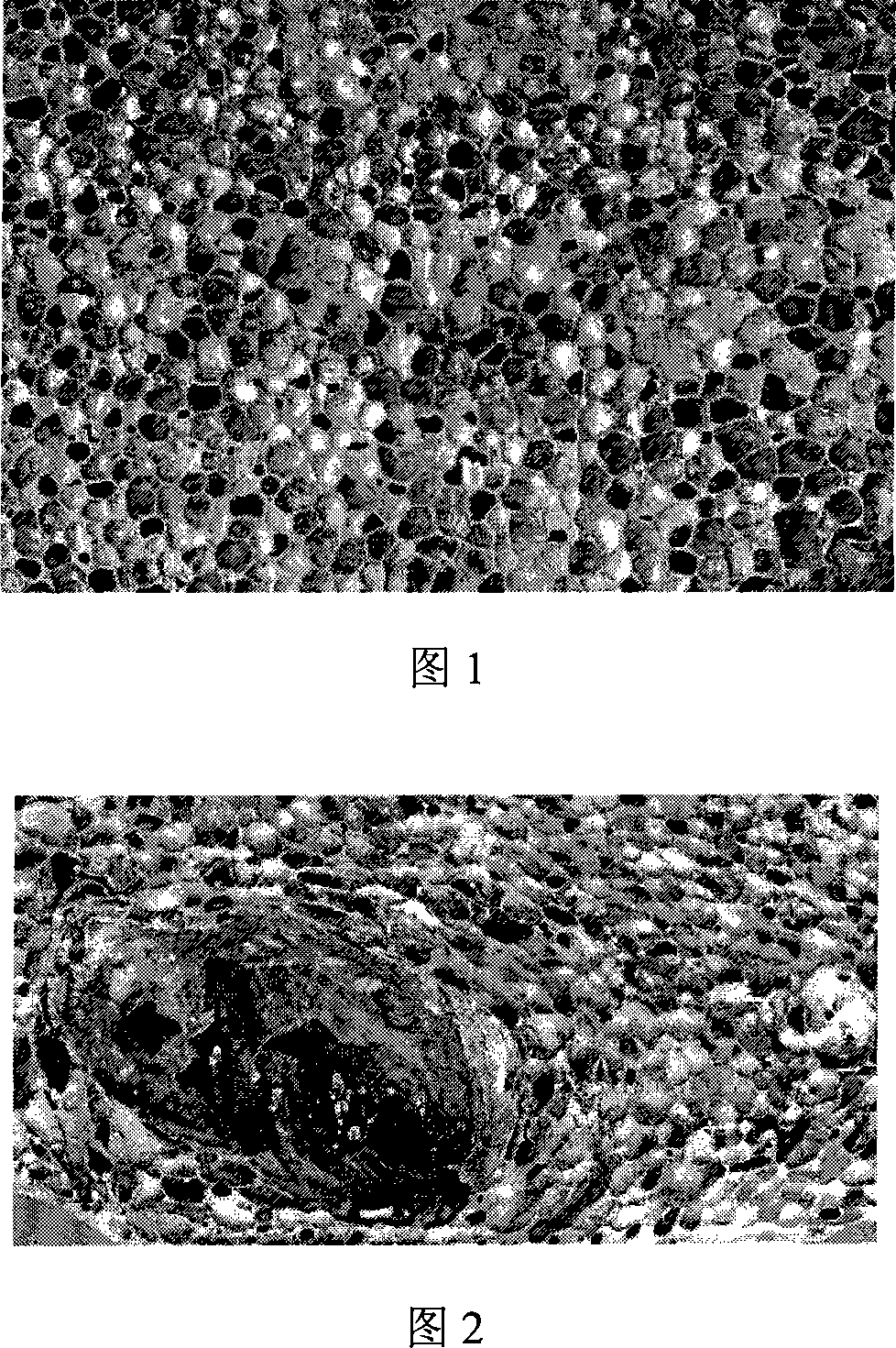

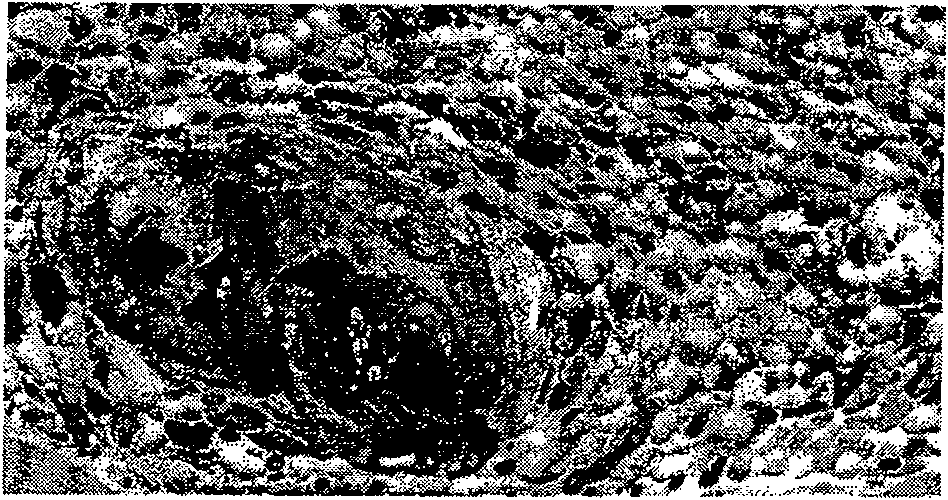

A supergravity method for preparing an aluminosilicate molecular sieve

InactiveCN108217674APrecise control of ratioControllable growth processChemical/physical/physico-chemical stationary reactorsCrystalline aluminosilicate zeolitesMolecular sieveProcess conditions

The invention provides a supergravity method for preparing an aluminosilicate molecular sieve, and belongs to the field of catalyst preparation. An internal-circulating supergravity reactor is adoptedas a reaction device. A silicon source and an aluminum source are pumped into the reactor at the same time through a liquid feeding pipe, and initial gel is obtained after the two raw materials are premixed. A rapid mixing characteristic of supergravity is utilized by a reaction system so that a raw material ratio under a microcosmic condition is accurately controlled and regulated, and crystallization is performed in a microcosmic and uniform environment, and therefore nucleating and growing processes are uniform and controllable, crystals grow uniformly, and particle size distribution is narrowed. Proper process conditions for preparing the molecular sieve are obtained through influences of process condition changes on the synthesized molecular sieve.

Owner:BEIJING UNIV OF CHEM TECH

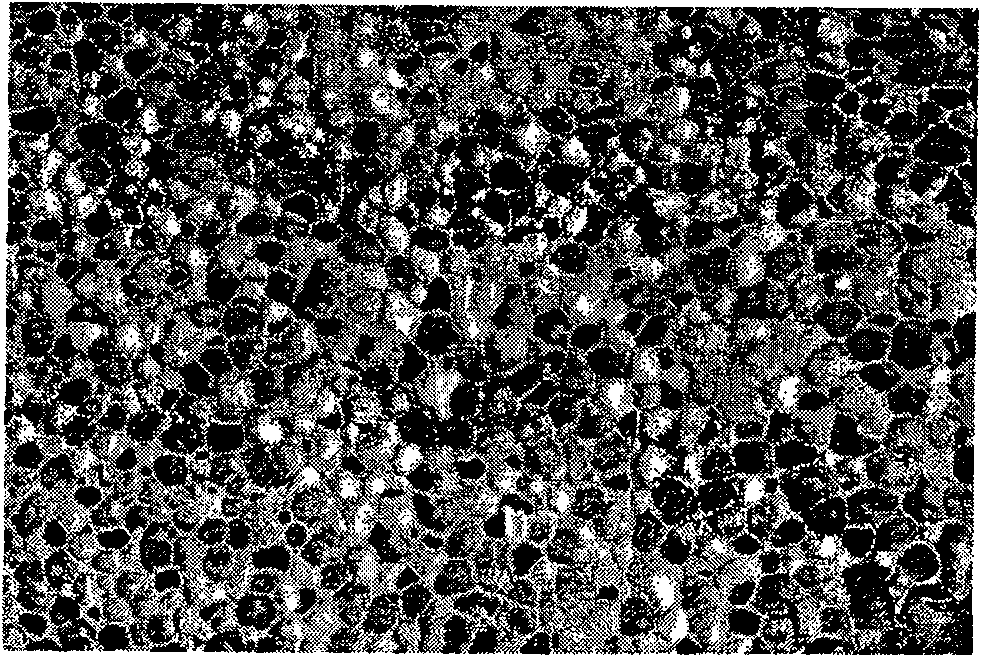

Method for producing bubble aluminum alloy special-shaped member with even pore structure

The invention discloses a method used for preparing a foaming aluminum alloy special form part with an even hole structure. The method comprises the following steps: firstly, aluminum alloy is warmed up to melt, titanium hydride is added, the mixing is performed to lead the titanium hydride to being deconcentrated, and then calcium is added to aluminum alloy solution, to be mixed and to add the viscosity of molten mass, the molten mass after being mixed is cooled down, and a fabricated part is obtained; secondly, the fabricated part is put in a die assembly, and heated and warmed up, and insulated at temperature, to lead the foaming aluminum alloy fabricated part to perform secondary foaming in the die assembly, foaming aluminum alloy after foaming is cooled down, to obtain a foaming aluminum alloy product. Before warming up to the secondary foaming in the second step, the primary foaming aluminum alloy fabricated part and the die assembly are firstly preheated and insulated. Before adding viscosity agent calcium, the titanium hydride is added firstly, the viscosity of the aluminum alloy solution is lower, and the invention is in favor of the titanium hydride being uniformly dispersed in the aluminum alloy molten mass within the shortest time, and in favor of preparing the large sized foaming aluminum alloy special form part with the even hole structure.

Owner:SOUTHEAST UNIV

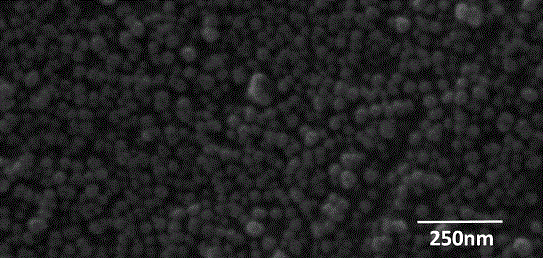

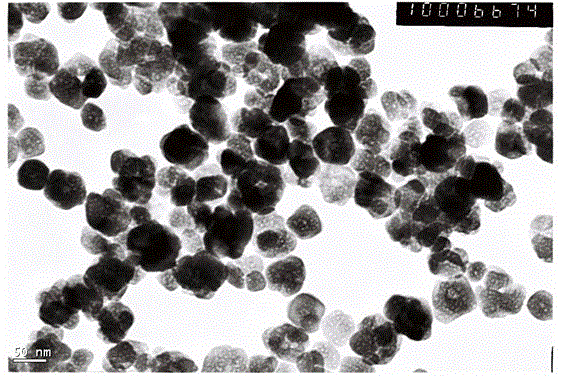

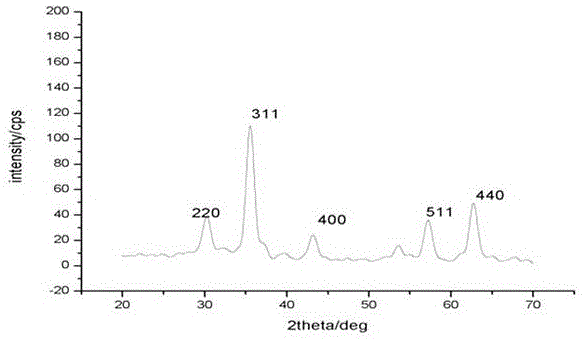

Preparation method of monodisperse super paramagnetic ferroferric oxide nanoparticles and ferroferric oxide nanoparticles

InactiveCN104649334ANot easily oxidizedGood compatibilityMaterial nanotechnologyFerroso-ferric oxidesIron nanoparticleSuperparamagnetism

The invention discloses a preparation method of monodisperse super paramagnetic ferroferric oxide nanoparticles and the ferroferric oxide nanoparticles. The preparation method comprises the following steps: preparing the monodisperse super paramagnetic ferroferric oxide nanoparticles by using a solvothermal method; performing surfactant polyacrylic acid modification on the Fe3O4 magnetic particles by using a hydrothermal method; and finally, dispersing into deionized water to obtain the monodisperse super paramagnetic ferroferric oxide nanoparticles. The prepared monodisperse super paramagnetic ferroferric oxide nanoparticles are uniform in particle size distribution of magnetic particles with average particle size of 75 nm, uniform in features, high in magnetic property of the particles, high in dispersibility and high in superparamagnetism; moreover, the specific saturation magnetization intensity of the particles can reach 78 emu / g at a maximum. The preparation method of the monodisperse super paramagnetic ferroferric oxide nanoparticles is convenient and easy, low in production cost, can be widely applied to the fields of machines, electronics, optics, magnetism, chemical engineering, biology and the like, and particularly, has great prospect on application of anti-cancer medicines on transmission and releasing.

Owner:SUN YAT SEN UNIV

Direct-spun black yarn FDY processing process based on master batch injection melt

ActiveCN102719908AAccurate measurementEnsure black uniformityNew-spun product collectionFilament-forming treatmentYarnDyeing

The invention relates to a direct-spun black yarn FDY (full drawn yarn) processing process based on master batch injection melt, which sequentially comprises the steps of: PET (polyethylene terephthalate) melt preparation, black master batch preparation, sufficient mixing of melt and spinning. According to the invention, the technical defects in the prior art of yarn floating during spinning, many broken ends, easiness in web yarn generation, large chroma difference generated while stopping spinning, nonuniform melt blending and the like are solved, and the benefits of saving subsequent dyeing and other aftertreatment processes, saving energy, reducing white slab transportation and fusion processes, saving a great deal energy, and realizing large-scale production of FDY black yarn with no filament breakage, low elasticity and excellent quality are achieved.

Owner:福建百宏聚纤科技实业有限公司

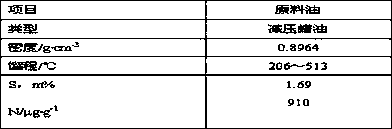

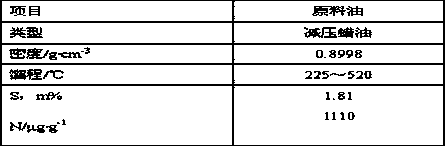

Method for coal tar hydrogenation for producing low solidifying point diesel oil

ActiveCN100558857CLittle impact on yieldIncreased yield impactLiquid hydrocarbon mixture productionTar working-up by distillationDistilled oilHydrogen

The invention relates to a method for producing diesel oil through hydrogenation modification, modification, isomerization and decondensation of coal tar. Separating coal tar into residual oil and distillate oil, using distillate oil as raw material, adopting a single-stage or series process flow, under suitable operating conditions, distillate oil raw material and hydrogen pass through the catalyst bed to obtain low freezing point diesel products And a small amount of naphtha products with low sulfur and nitrogen content. It is characterized in that the catalyst bed includes a hydrogenation treatment catalyst bed containing 0.5-<20wt% of zeolite beta. The key point of this technology is that it can directly provide high-quality diesel products with low freezing point and high cetane number, and at the same time provide a suitable technological route for the rational application of coal tar.

Owner:CHINA PETROLEUM & CHEM CORP +1

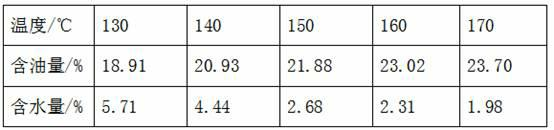

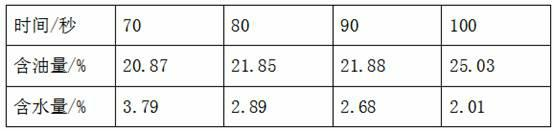

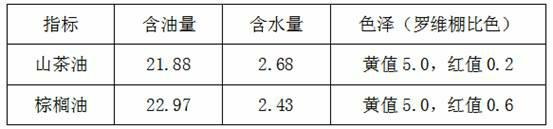

Method for preparing camellia oil instant noodle

InactiveCN102550953ASuitable process conditionsReduce oil contentFood preparationNational standardInstant noodle

The invention discloses a method for preparing a camellia oil instant noodle, which comprises the following steps of: taking high-gluten wheat flour as a main raw material, preparing the flour into dough by adding a proper amount of water, and cooking, calendering, slitting, steaming, cutting and folding to obtain cooked noodle; frying the noodle in 130-170 DGE C camellia oil for 70-100 s, draining the oil, cooling the noodle, adding seasoning packets, and packaging the noodle and the seasoning packets to obtain the finished product of instant noodle. In the method, camellia oil is successfully adopted to produce the high-quality fried instant noodle, the instant noodle has golden color without adding any pigment and has low oil content which is 21.9%, the water content is 2.7%, and the rest various indexes reach the requirements of the national standard. Moreover, the instant noodle has long shelf life, does not have rancio taste of fat oxidation and has inherent smell and taste of oil-tea camellia seed oil.

Owner:福家欢食品股份有限公司

Method for producing oil by utilizing rice bran

InactiveCN106635387ASimple processSuitable process conditionsFatty-oils/fats refiningFatty-oils/fats productionCooking & bakingFiltration

The invention provides a method for producing oil by utilizing rice bran. The method comprises the following steps that 1, rice bran is cleaned; 2, shells and water is added; 3, the rice bran is steamed and stir-fried, wherein the rice bran processed in the step 2 is steamed and stir-fried by using a steaming and stir-drying machine to obtain cooked germs, the rotating speed of the steaming and stir-drying machine is 50-60 r / min, and the rice bran moisture is up to 32%-37%; 4, germ stir-drying is performed, wherein the cooked germs obtained in the step 3 are put in an iron pan for baking and stir-drying; 5, squeezing is performed, wherein a c cake block obtained in the step 4 is put in an oil press and is jacked in the oil pressing process, slow force exertion is performed for squeezing, the squeezing temperature is 80-90 DEG C, and the time is 3-5 minutes; 5, filtration is performed; 6, hydration and dehydration are performed. The method for producing oil by utilizing the rice bran uses the rice bran as a raw material, adopts a squeezing technology and is simple in process, high in oil yield and free of pollution, and process conditions are suitable.

Owner:安徽荒草圩生态农业有限公司

Method for producing bubble aluminum alloy special-shaped member with even pore structure

The invention discloses a method for preparing a foamed aluminum alloy special-shaped piece with a uniform pore structure, which comprises the following steps: the first step: heating the aluminum alloy to melt, adding titanium hydride, stirring to disperse the titanium hydride, and then adding calcium to aluminum In the molten alloy, stir to increase the viscosity of the melt, cool the stirred melt to obtain a preform; the second step: put the above preform into the mold, heat it up, and keep it warm at this temperature, The primary foamed aluminum alloy prefabricated part is made into secondary foam in the mould, and the foamed aluminum alloy is cooled to obtain a foamed aluminum alloy product. In the second step, before the secondary foaming is heated up, the primary foamed aluminum alloy prefabricated part and the mold are preheated and kept warm. In the present invention, titanium hydride is added before the tackifier calcium is added, and the viscosity of the aluminum alloy melt is low, which is conducive to the uniform dispersion of titanium hydride in the aluminum alloy melt in a relatively short period of time, and is conducive to the preparation of a uniform pore structure. Dimensional foam aluminum alloy profiled parts.

Owner:SOUTHEAST UNIV

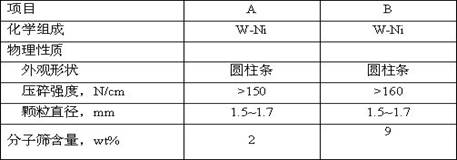

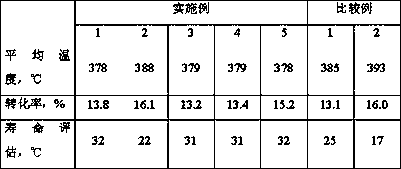

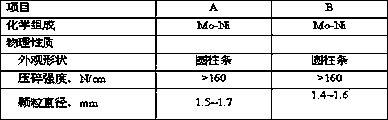

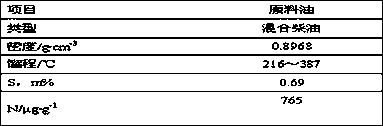

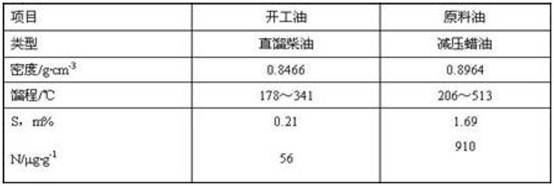

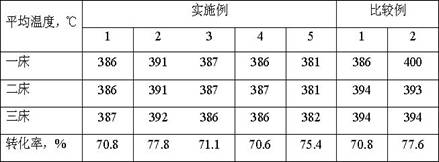

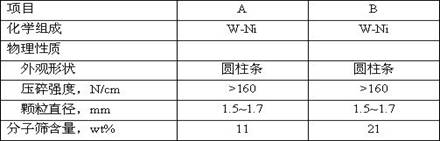

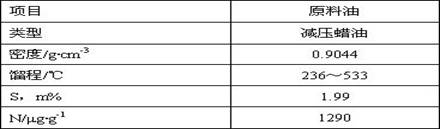

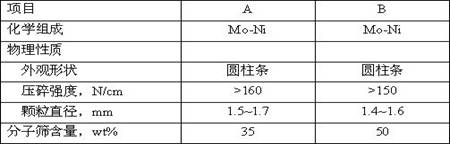

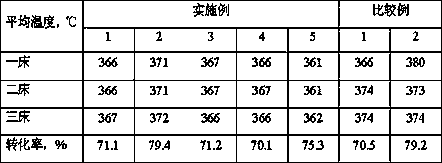

Hydrocracking commencement method

ActiveCN109777486AIntensified vulcanization process inside the extenderHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsTreatment with hydrotreatment processesHydrogenVulcanization

The invention discloses a hydrocracking commencement method which comprises the following steps: firstly, introducing low-nitrogen commencement oil, hydrogen and a vulcanizing agent into a hydrocracking device, carrying out constant-temperature vulcanization on a hydrocracking catalyst at 220-260 DEG C, when the content of hydrogen sulfide in circulated hydrogen is up to 3000-5000ppm, reducing theaddition velocity of the vulcanizing agent, and increasing the temperature of a hydrocracking catalyst bed layer, when the temperature of the hydrocracking catalyst bed layer is up to 310-330 DEG C,increasing the addition velocity of the vulcanizing agent, continuously carrying out constant-temperature vulcanization, increasing the temperature to 380-390 DEG C, and introducing raw material oil to carry out a reaction, wherein the hydrocracking catalyst has 0.3-4% by weight of a nitrogen element, and the nitrogen element is derived from low-molecule-weight nitride and strong alkali cyclic nitride. The method is short in time for commencement, raw material switching and stable production state start, the consumption of a passivant in the commencement process and potential danger in the ammonia injection process can be avoided, and not only is energy consumption reduced, but also environment pollution and human body damage caused by the passivant can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

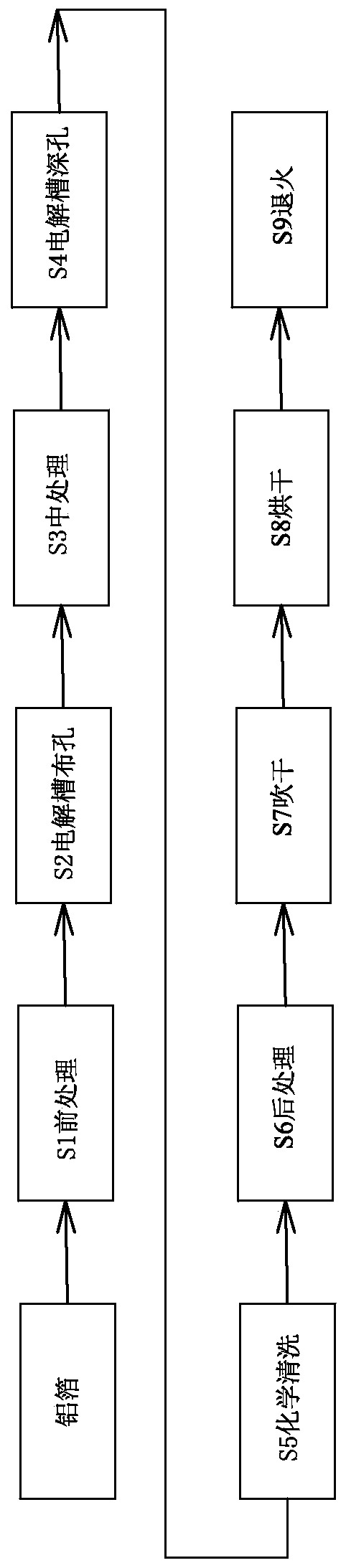

Aluminum electrolytic capacitor low-voltage aluminum foil corrosion process

InactiveCN111508713AUniform sizeLarge specific surface areaElectrolytic capacitorsMetallurgyAluminum foil

The invention provides an aluminum electrolytic capacitor low-voltage aluminum foil corrosion process, which comprises the following steps of S1, pretreatment, S2, electrolytic cell hole distribution,S3, intermediate treatment, S4, electrolytic cell deep hole, S5, chemical cleaning, S6, post-treatment, S7, blow-drying, S8, drying, and S9, annealing. In order to overcome the defects in the prior art, the invention provides the low-voltage aluminum foil corrosion process for the aluminum electrolytic capacitor, wherein the process is proper in process condition and reasonable in corrosive liquid component proportion, so that the pore density is high and uniform.

Owner:恒扬(韶关)工业有限公司

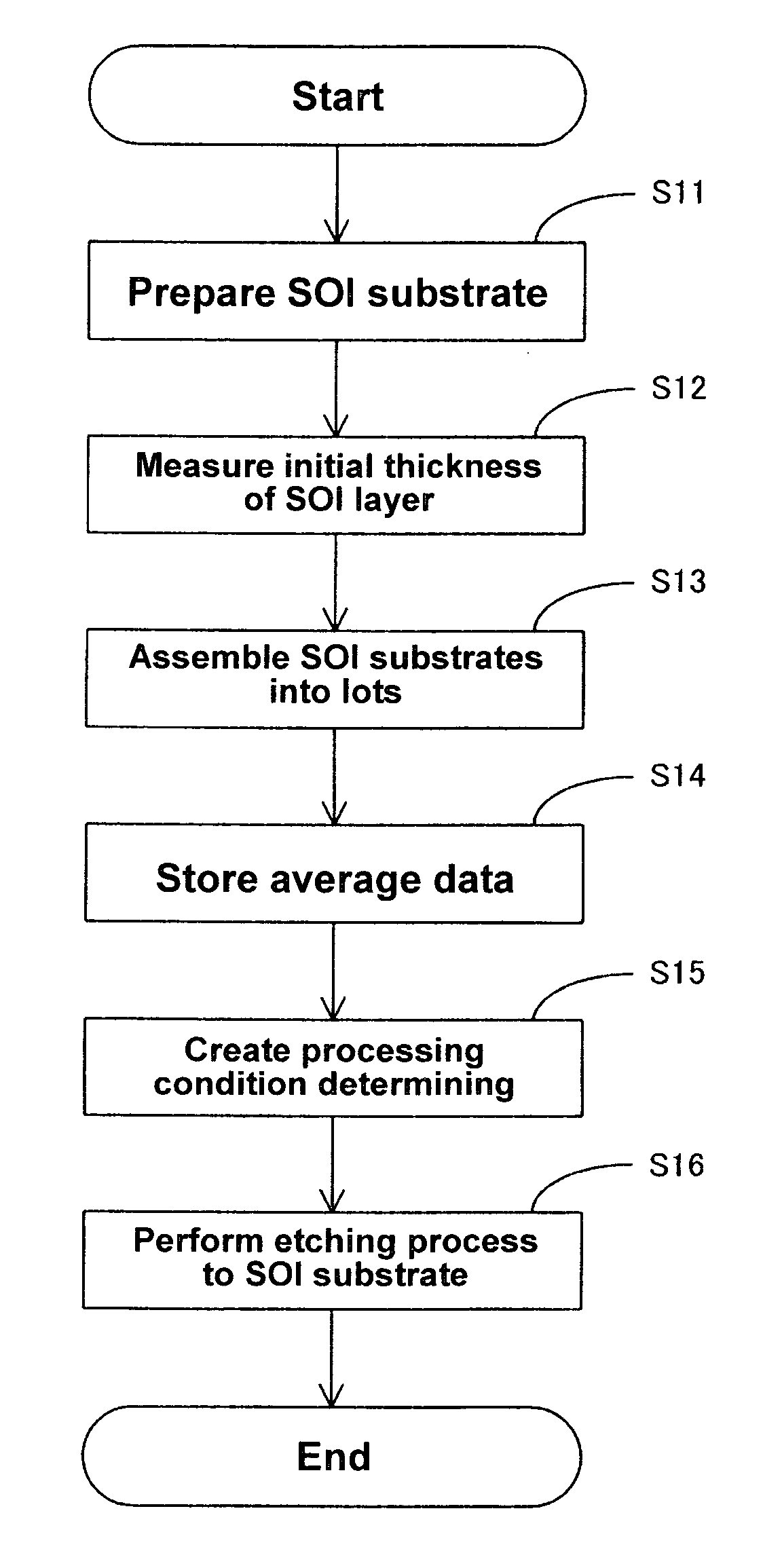

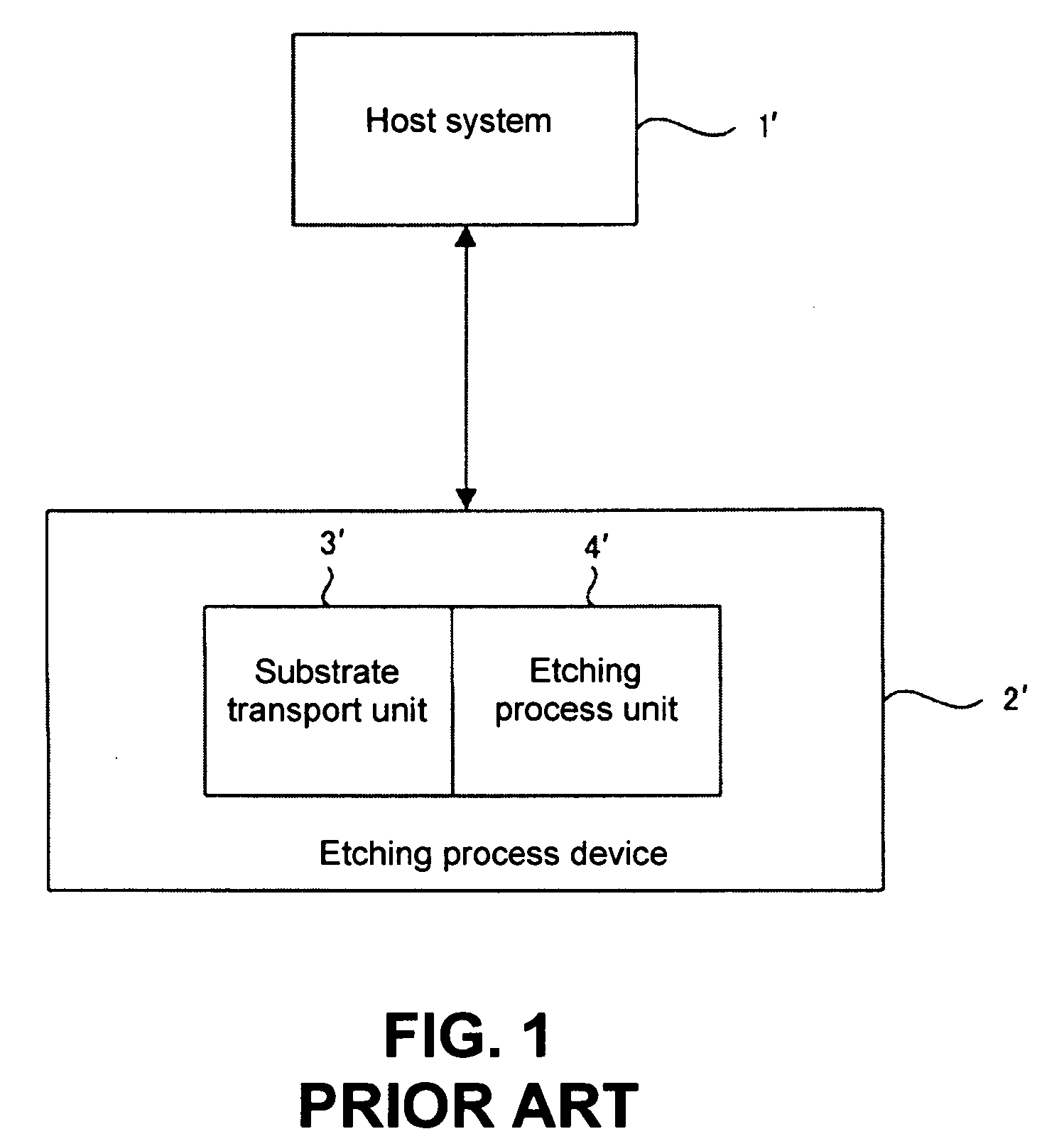

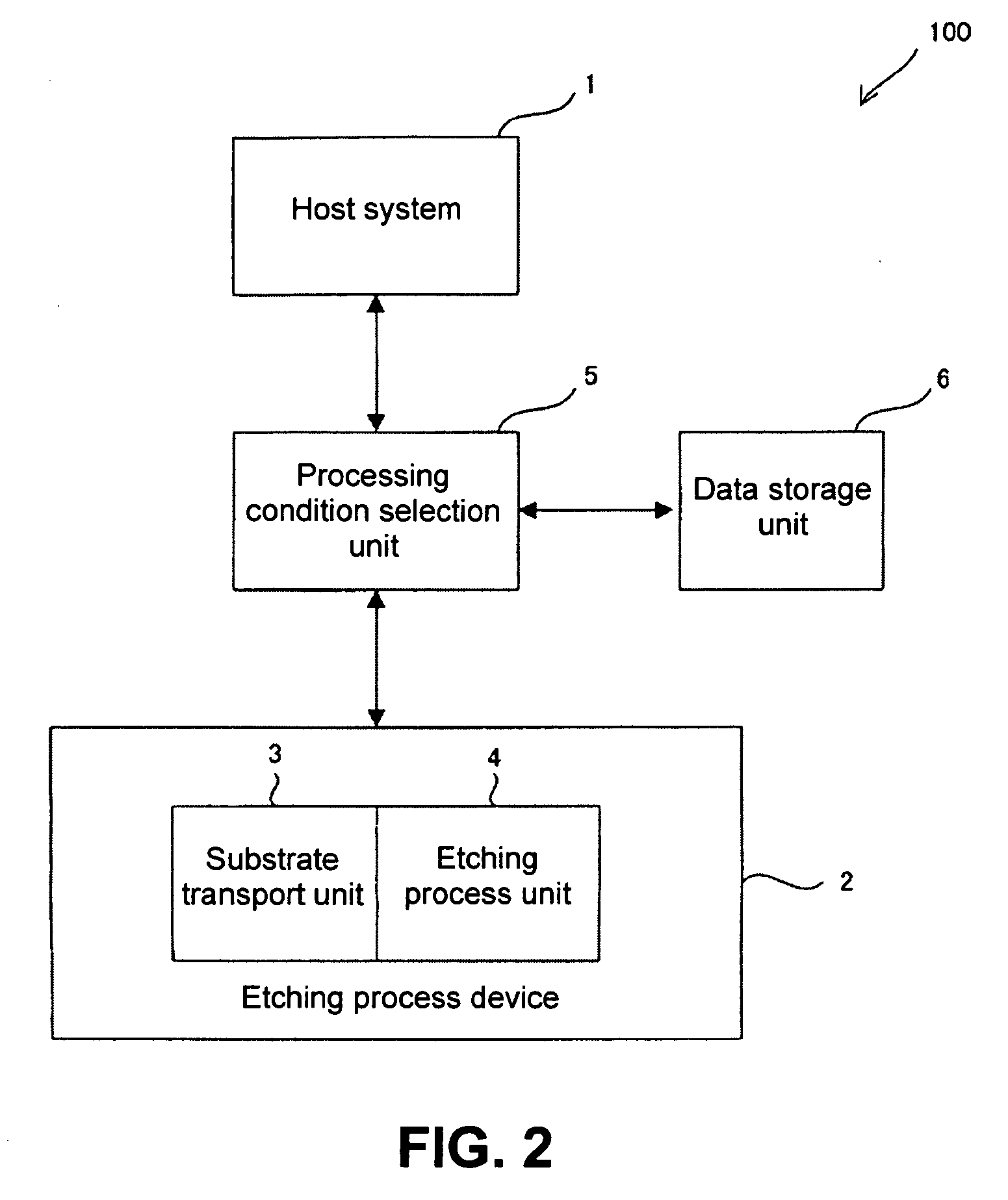

Method of processing semiconductor substrate and processing apparatus

InactiveUS20090164040A1Uniform structureSuitable process conditionsProgramme controlSolid-state devicesComputer hardwareSemiconductor

A method of processing semiconductor substrates includes the steps of: storing attribution data indicating an attribution of each of the semiconductor substrates in a recording medium according to piece identification codes of the semiconductor substrates; generating a start direction accompanying one of the piece identification codes of the semiconductor substrates with a control unit; retrieving the attribution data corresponding to one of the semiconductor substrate related to the start direction from the recording medium with a processing condition setting unit; selecting one of processing conditions according to the attribution data thus retrieved and a processing condition determining table in which a plurality of the processing conditions is set according to the attributions of the semiconductor substrates with the processing condition setting unit; and processing one of the semiconductor substrates related to the start direction under the one of the processing conditions thus selected with a processing unit.

Owner:LAPIS SEMICON CO LTD

Electrolytic preparing method for high-energy alkaline primary cell anode material

InactiveCN1581539AEasy to deep oxidationSuitable process conditionsElectrode manufacturing processesElectrolysis componentsElectrolysisHigh energy

The invention related to method for preparing hydroxy-nickel oxide includes following steps: dissolving nickel chloride in deionized water and preparing electrolyte; adding the said electrolyte into electrobath with inert material being as electrode; adjusting pH value and carrying out electroanalysis step; taking hydroxy-nickel oxide on anodic plate off, through cleaning, drying, milling and sieving steps to obtain hydroxy-nickel oxide. Comparing with procedure of using nickel hydroxide, the invented method possesses advantages as follows: low cost, high efficiency, with no wastewater treatment, carrying out reaction system in closed cycle, and availability of equipment for producing manganese dioxide.

Owner:XIAMEN UNIV

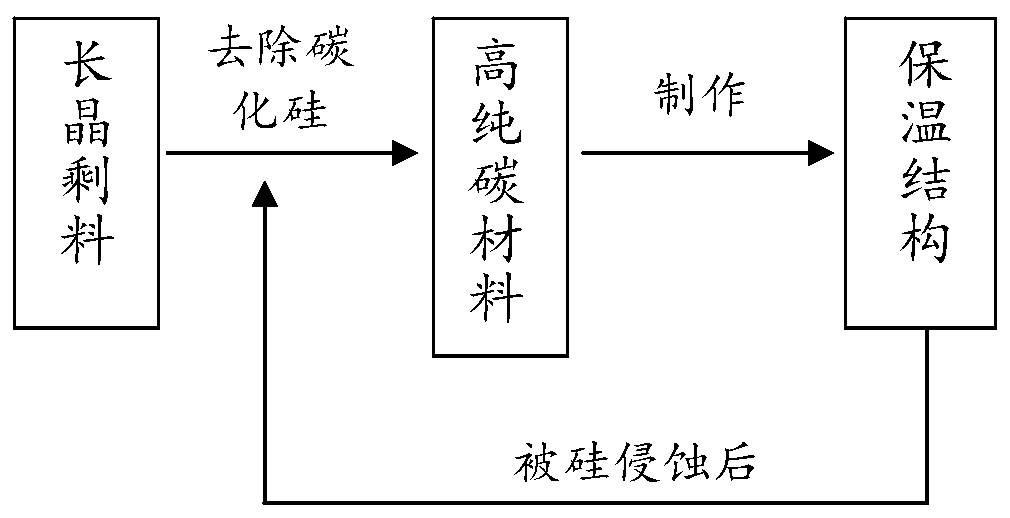

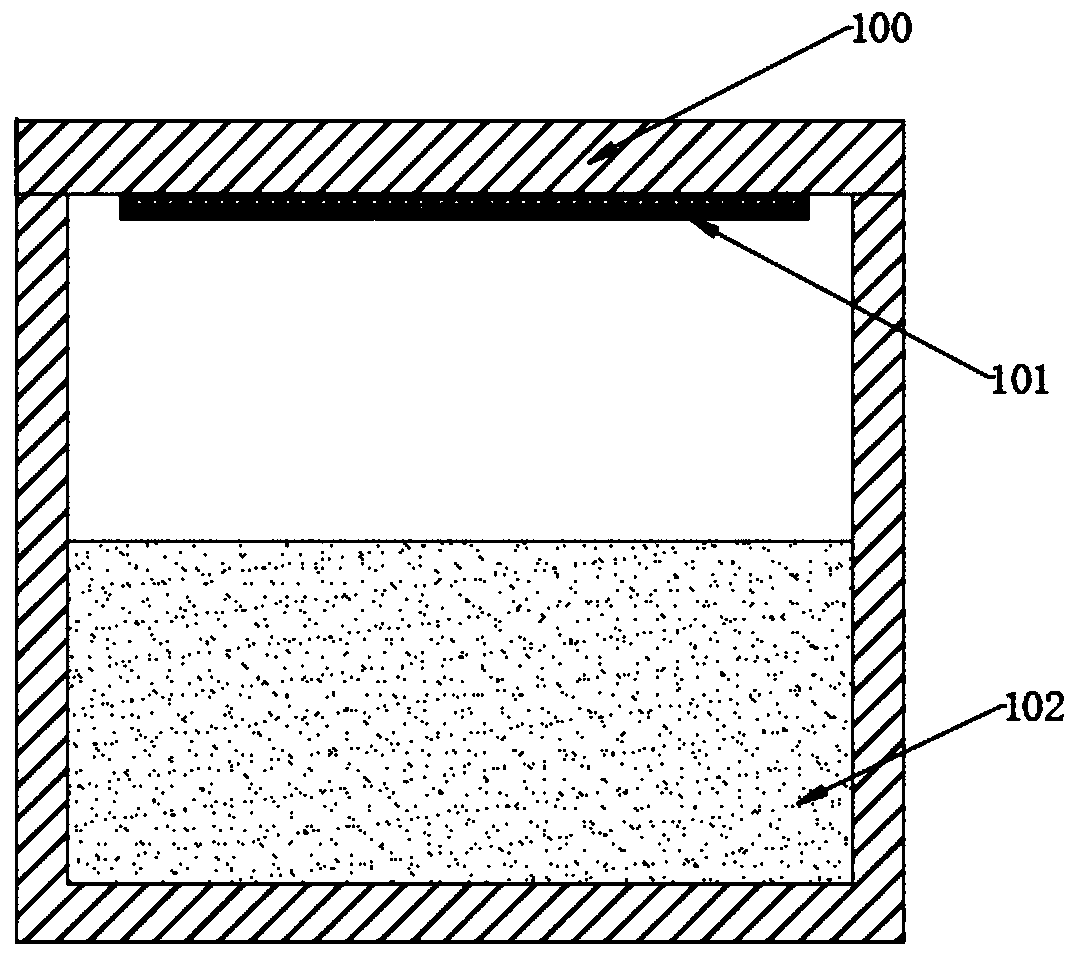

Comprehensive Utilization Method of Silicon Carbide Crystal Growth Leftovers

ActiveCN109280977BHigh puritySimple methodAfter-treatment apparatusPolycrystalline material growthThermal insulationNucleation

Owner:SICC CO LTD

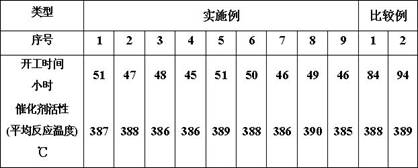

A wet start-up method for hydrocracking

ActiveCN109777474BIntensified vulcanization process inside the extenderHigh activityHydrocarbon oil crackingPtru catalystPhysical chemistry

The invention discloses a hydrocracking commencement method which comprises the following steps: firstly, introducing low-nitrogen commencement oil, nitrogen and a vulcanizing agent into a hydrocracking device, carrying out constant-temperature vulcanization on a hydrocracking catalyst at 220-260 DEG C, reducing the addition velocity of the vulcanizing agent and increasing the temperature of a hydrocracking catalyst bed layer when the content of hydrogen sulfide in circulation hydrogen is up to 3000-5000ppm, increasing the addition velocity of the vulcanizing agent when the temperature of thehydrocracking catalyst bed layer is up to 310-330 DEG C, carrying out constant-temperature vulcanization continuously, increasing the temperature to 360-370 DEG C, and introducing raw material oil tocarry out reactions, wherein the hydrocracking catalyst comprises 0.4-6%, preferably 0.5-4%, of nitrogen elements in percentage by weight, and the nitrogen elements are derived from low-molecule nitride and alkalescent or non-alkaline annular nitride. By adopting the method, the time for commencement, raw material switching and production state stabilization is short, consumption of a passivant inthe commencement process is avoided, potential danger in the ammonia injection process is avoided, and not only is energy consumption reduced, but also environmental pollution and human body damage caused by the passivant can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking start-up method

ActiveCN109777486BIntensified vulcanization process inside the extenderHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsTreatment with hydrotreatment processesPtru catalystPhysical chemistry

The invention discloses a hydrocracking start-up method, which includes the following contents: firstly, introducing low-nitrogen start-up oil, hydrogen and vulcanizing agent into the hydrocracking unit, and then performing constant temperature vulcanization on the hydrocracking catalyst under the condition of 220-260°C, After the hydrogen sulfide content in the circulating hydrogen reaches 3000-5000ppm, reduce the adding rate of the sulfiding agent and increase the bed temperature of the hydrocracking catalyst, and increase the adding rate of the sulfiding agent when the bed temperature of the hydrocracking catalyst reaches 310°C-330°C , after continuing the constant temperature vulcanization, raise the temperature to 380°C-390°C and feed the raw oil for reaction, wherein the hydrocracking catalyst contains 0.3%-4% nitrogen element by weight percentage, and the nitrogen element comes from low molecular nitrogen compounds and strongly basic cyclic nitrides. The method has the advantages of short time required for starting up, switching raw materials and entering a stable production state, avoiding the consumption of passivating agent during the starting process and the potential danger in the ammonia injection process, not only saving energy consumption, but also reducing the impact of passivating agent on the environment Pollution and harm to the human body.

Owner:CHINA PETROLEUM & CHEM CORP +1

Methods of Improving the Operational Safety of Hydrocracking Units

ActiveCN111100687BHigh activityAchieve reasonable utilizationMolecular sieve catalystsTreatment with hydrotreatment processesPtru catalystReaction temperature

The invention discloses a method for improving the operation safety of a hydrocracking unit. The hydrocracking unit contains at least two hydrocracking catalyst beds. When the nitrogen weight in the hydrocracking catalyst in the first hydrocracking catalyst bed is When the percentage content is 0.15~0.35%, cool down to 200~340°C to switch the hydrocracking feed oil with a nitrogen content of 300~500ppm, and switch the nitrogen content when the nitrogen content in the hydrocracking effluent is constant at 50~80ppm For hydrorefined oil less than 40ppm, adjust the reaction temperature of the hydrocracking section so that the mass yield of light oil <360°C is finally constant at 35~40%, and the total constant time is 48~96 hours, and then adjust to hydrocracking Reaction conditions The hydrocracking reaction is carried out. The method solves the problem that the activity of some hydrocracking catalysts is damaged due to frequent start-up and shutdown, thereby affecting the mismatch of reaction temperatures between different catalyst beds in the reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

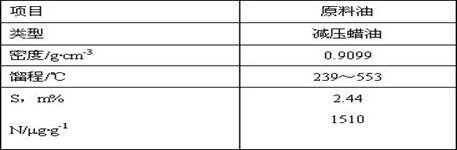

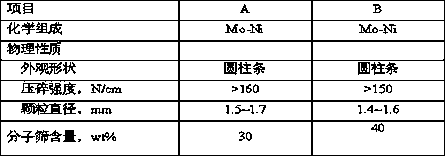

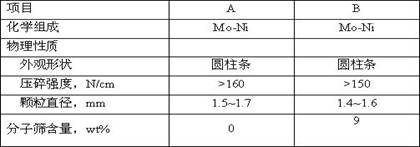

Method for recovering activity of low-activity hydro-upgrading catalyst

ActiveCN111097492AAvoid gradual "pre-resurrection"Solve the root problem of low activityMolecular sieve catalystsHydrocarbon oils refiningMolecular sievePtru catalyst

The invention discloses a method for recovering the activity of a low-activity hydro-upgrading catalyst, comprising the following steps: introducing nitrogen with the content of 0-10mu g / g into the low-activity hydro-upgrading catalyst bed, adjusting the reaction temperature of the upgrading section to enable the mass yield of the light oil of being less than 175 DEG C to be 20%-30% constantly for24-48 hours, and adjusting to hydro-upgrading conditions for reaction after the completion of the constant reaction. The low-activity hydro-upgrading catalyst comprises, by weight, 0%-less than 20% of a molecular sieve and 0.15%-0.35% of a nitrogen element, wherein the molecular sieve comprises at least one of a Y-type molecular sieve and a USY molecular sieve. The method has the advantages of simple process and stable operation, and solves the problem of how to recover the activity of the hydro-upgrading catalyst due to reduction of the activity of the hydro-upgrading catalyst caused by long-term operation according to a hydrofining mode.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of stable start-up method of hydrocracking catalyst

ActiveCN109777477BAvoid investmentHigh activityHydrotreatment operations starting-upHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a stable start-up method for a hydrocracking catalyst. In the start-up method, raw material oil is introduced during the vulcanization process, and the reaction temperature is adjusted after the vulcanization is completed so that the mass yield of light oil at <360°C is constant at 65-70%. Adjust to the hydrocracking reaction conditions to carry out the hydrocracking reaction, the hydrocracking catalyst contains 50%-70% molecular sieve by weight, and the molecular sieve includes but not limited to Y-type or USY molecular sieve. The method has the advantages of simple start-up and raw material switching process, stable operation, and avoids the consumption of passivating agent and the potential danger in the ammonia injection process during start-up.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for activity recovery of low-activity hydrogenation upgrading catalyst

ActiveCN111097492BGood recovery effectHigh activityMolecular sieve catalystsHydrocarbon oils refiningMolecular sievePtru catalyst

The invention discloses a method for recovering the activity of a low-activity hydrogenation-modifying catalyst. The nitrogen content of 0-10 μg / g is introduced into the low-activity hydrogenation-modifying catalyst bed, and the reaction temperature of the reforming section is adjusted to < The mass yield of light oil at 175°C is constant at 20% to 30%, and the constant time is 24 to 48 hours. After the constant is over, it is adjusted to the hydrogenation upgrading condition for reaction; It contains 0%-less than 20% molecular sieve and 0.15%-0.35% nitrogen element, and the molecular sieve includes at least one of Y-type or USY molecular sieves. The method has the advantages of simple process and stable operation, and solves the problem of how to restore the activity reduction of the hydrogenation reforming catalyst caused by long-term operation in the hydrogenation refining mode.

Owner:CHINA PETROLEUM & CHEM CORP +1

Methods of Improving the Smooth Operation of Hydrocracking Units

ActiveCN111100686BImprove passivation effectExcess activity inhibitionMolecular sieve catalystsTreatment with hydrotreatment processesThermodynamicsPtru catalyst

The invention discloses a method for improving the stable operation of a hydrocracking unit. The hydrocracking unit contains at least two hydrocracking catalyst beds. When the nitrogen in the hydrocracking catalyst in the first hydrocracking catalyst bed is When the nitrogen content is 0.2~0.45%, the temperature is lowered to 200~340°C to switch the hydrocracking feed oil with a nitrogen content of 300~500ppm. When the nitrogen content in the hydrocracking effluent is constant at 50~80ppm, switch the nitrogen content to less than 20ppm of hydrorefined oil, while adjusting the reaction temperature of the hydrocracking section so that the mass yield of light oil <360°C is finally constant at 55~60%, and the constant time is 24~48 hours, and then adjusted to the hydrocracking reaction conditions carry out hydrocracking reactions. The method solves the problem that the activity of some hydrocracking catalysts is damaged due to frequent start-up and shutdown, thereby affecting the mismatch of reaction temperatures between different catalyst beds in the reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

A Method of Improving the Operation Safety of Hydrocracking Unit

ActiveCN111100689BHigh activityAchieve reasonable utilizationMolecular sieve catalystsTreatment with hydrotreatment processesPtru catalystReaction temperature

The invention discloses a method for improving the operation safety of a hydrocracking unit. The hydrocracking unit contains at least two hydrocracking catalyst beds. When the nitrogen weight in the hydrocracking catalyst in the first hydrocracking catalyst bed is When the percentage content is 0.15~0.4%, lower the temperature to 200~340℃ and switch the hydrocracking feed oil with nitrogen content of 300~500ppm, and switch the nitrogen content when the nitrogen content in the hydrocracking effluent is constant at 50~80ppm For hydrorefined oil less than 30ppm, adjust the reaction temperature of the hydrocracking section so that the mass yield of light oil <360°C is finally constant at 45~50%, and the total constant time is 24~48 hours, and then adjust to hydrocracking Reaction conditions The hydrocracking reaction is carried out. The method solves the problem that the activity of some hydrocracking catalysts is damaged due to frequent start-up and shutdown, thereby affecting the mismatch of reaction temperatures between different catalyst beds in the reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

A safe start-up method for hydrocracking catalyst

The invention discloses a safe start-up method for a hydrocracking catalyst. In the start-up method, raw material oil is introduced during the vulcanization process, and the reaction temperature is adjusted after the vulcanization is completed, so that the mass yield of light oil at <360°C is constant at 55-60%. Adjust to the hydrocracking reaction conditions to carry out the hydrocracking reaction, the hydrocracking catalyst contains 30% to 50% molecular sieve by weight, and the molecular sieve includes but not limited to Y type or USY type. The method has the advantages of simple start-up and raw material switching process, stable operation, and avoids the consumption of passivating agent and the potential danger in the ammonia injection process during start-up.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving stable operation of hydrocracking unit

ActiveCN111100688AHigh activityAchieve reasonable utilizationTreatment with hydrotreatment processesThermodynamicsPtru catalyst

The invention discloses a method for improving stable operation of a hydrocracking unit. The hydrocracking unit at least comprises two hydrocracking catalyst beds. The method comprises the following steps: cooling to 200-340 DEG C and switching the hydrocracking feed oil with the nitrogen content of 300 to 500 ppm when the weight percentage content of nitrogen in the hydrocracking catalyst in thefirst hydrocracking catalyst bed is 0.25-0.5%; switching the hydrofined oil with the nitrogen content of less than 10ppm when the nitrogen content in the hydrocracking effluent is constant at 50-80ppm; simultaneously adjusting the reaction temperature of the hydrocracking section until the mass yield of the light oil of less than 360 DEG C is finally kept constant at 65-70% and the total constanttime is 24-48 hours; and then adjusting to the hydrocracking reaction conditions to carry out a hydrocracking reaction. By the method, the problem that the activity of part of the hydrocracking catalyst is damaged due to frequent startup and shutdown and the mismatching of reaction temperatures among different catalyst beds in the reactor is influenced is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving stable operation of hydrocracking unit

ActiveCN111100686AHigh activityAchieve reasonable utilizationTreatment with hydrotreatment processesThermodynamicsPtru catalyst

The invention discloses a method for improving stable operation of a hydrocracking unit. The hydrocracking unit at least involves two hydrocracking catalyst beds. The method comprises the following steps: cooling to 200-340 DEG C and switching the hydrocracking feed oil with the nitrogen content of 300 to 500 ppm when the weight percentage content of nitrogen in a hydrocracking catalyst in the first hydrocracking catalyst bed is 0.2-0.45%; switching the hydrofined oil with the nitrogen content of less than 20ppm when the nitrogen content in the hydrocracking effluent is constant at 50-80ppm; simultaneously adjusting the reaction temperature of the hydrocracking section until the mass yield of the light oil of less than 360 DEG C is finally kept constant at 55-60% and the constant time is 24-48 hours; and then adjusting to the hydrocracking reaction condition for hydrocracking reaction. By the method, the problem that the activity of part of the hydrocracking catalyst is damaged due tofrequent startup and shutdown and then the mismatching of reaction temperatures among different catalyst beds in the reactor is influenced is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of rapid start-up method of hydrocracking catalyst

The invention relates to a rapid start-up method for a hydrocracking catalyst. In the start-up method, raw material oil is introduced during the vulcanization process, and the reaction temperature is adjusted after the vulcanization is completed so that the mass yield of light oil at <360°C is constant at 35-40%. The hydrocracking reaction is carried out under the conditions of the hydrocracking reaction, and the hydrocracking catalyst contains 0% to 10% molecular sieve by weight, and the molecular sieve includes but not limited to Y type or USY type. The method has the advantages of simple start-up and raw material switching process, stable operation, and avoids the consumption of passivating agent and the potential danger in the ammonia injection process during start-up.

Owner:CHINA PETROLEUM & CHEM CORP +1

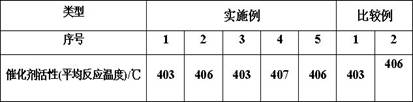

Novel method for preparing high-proportion trans, trans-4-(4'-alkyl cyclohexyl) cyclohexyl alcohol liquid crystal intermediate compound

ActiveCN101704724BMeet purity requirementsImprove quality requirementsOrganic compound preparationHydroxy compound preparationFiltrationKetone

The invention relates to a method for preparing a high-proportion trans, trans-4-(4'-alkyl cyclohexyl) cyclohexyl alcohol liquid crystal intermediate compound. The method comprises the following steps of: dissolving trans-4-alkyl cyclohexyl cyclohexyl ketone in an organic solvent (A); dissolving reductant boron hydride in an organic solvent (B); mixing the two obtained mixed solution; carrying out reduction reaction; carrying out transposition reaction by using Lewis acid; then carrying out acid hydrolysis; carrying out extraction by using a solvent; merging organic phases; washing the solution until the pH value is 7; adding desiccant to dry obtained products; removing the desiccant by filtration; and removing the solvent under low vacuum to obtain the high-proportion trans, trans-4-(4'-alkyl cyclohexyl) cyclohexyl alcohol liquid crystal intermediate compound. The method is simple in process and high in yield, and is favorable for realizing scale production.

Owner:YANTAI DERUN LIQUID CRYSTAL MATERIALS

A method for activity recovery of low-activity hydrogenation upgrading catalyst

ActiveCN111097552BAvoid gradual "pre-resurrection"Solve the root problem of low activityCatalyst regeneration/reactivationHydrocarbon oils treatmentMolecular sievePtru catalyst

The invention discloses a method for recovering the activity of a low-activity hydrogenation upgrading catalyst. The method is as follows: feed refined oil with a nitrogen content of 0-10 μg / g into the low-activity hydrogenation upgrading catalyst bed, and at the same time adjust the reaction temperature in the upgrading section so that the mass yield of light oil at <175°C is constant at 40 % to 50%, the constant time is 24 to 48 hours, and after the constant is completed, adjust to the hydrogenation and upgrading conditions to react; the low activity hydrogenation and upgrading catalyst contains 50% to 70% of molecular sieves by weight, 0.25 % to 0.45% nitrogen, the molecular sieves include at least one of Y-type or USY molecular sieves. The method has the advantages of simple process and stable operation, and solves the problem of how to restore the activity reduction of the hydrogenation reforming catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Direct-spun black yarn FDY processing process based on master batch injection melt

ActiveCN102719908BEnsure black uniformityAccurate measurementNew-spun product collectionFilament-forming treatmentState of artYarn

The invention relates to a direct-spun black yarn FDY (full drawn yarn) processing process based on master batch injection melt, which sequentially comprises the steps of: PET (polyethylene terephthalate) melt preparation, black master batch preparation, sufficient mixing of melt and spinning. According to the invention, the technical defects in the prior art of yarn floating during spinning, many broken ends, easiness in web yarn generation, large chroma difference generated while stopping spinning, nonuniform melt blending and the like are solved, and the benefits of saving subsequent dyeing and other aftertreatment processes, saving energy, reducing white slab transportation and fusion processes, saving a great deal energy, and realizing large-scale production of FDY black yarn with no filament breakage, low elasticity and excellent quality are achieved.

Owner:福建百宏聚纤科技实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com