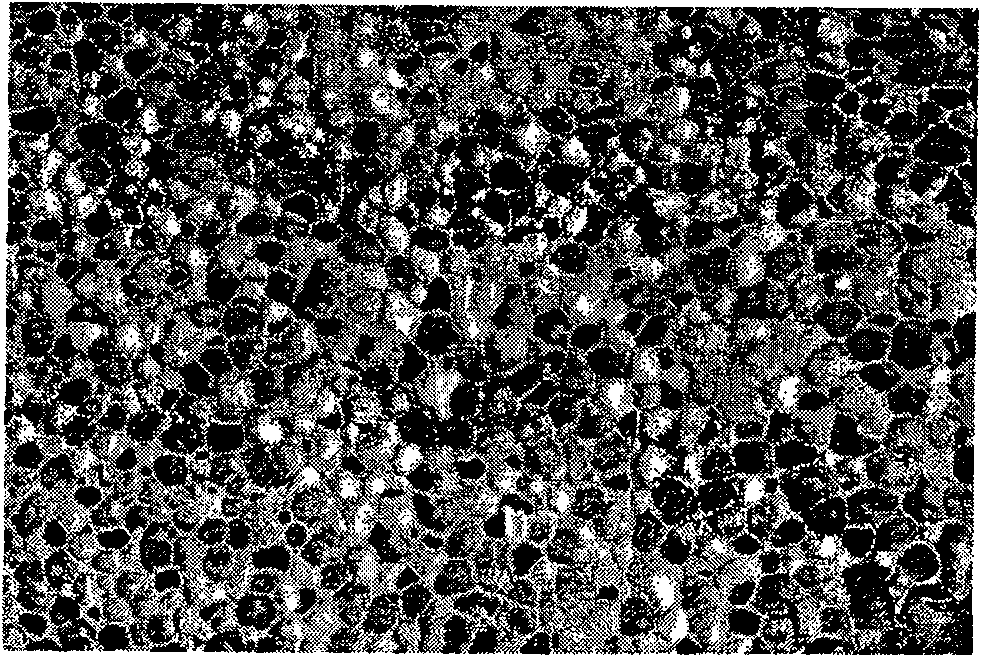

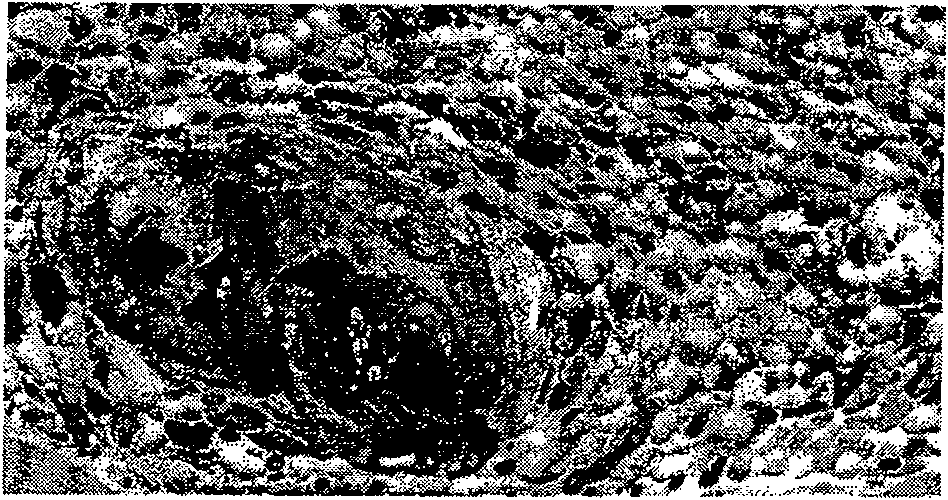

Method for producing bubble aluminum alloy special-shaped member with even pore structure

A foamed aluminum alloy and aluminum alloy technology, which is applied in the field of preparing foamed aluminum alloy special-shaped parts with a uniform pore structure, can solve the problems of large amount of outgassing, concentrated shrinkage cavities, and unstable process, and achieve simplified process, uniform pore structure, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing a foamed aluminum alloy shaped part with a uniform pore structure, comprising the following steps:

[0022]Step 1: Heat the aluminum alloy until it melts. Among them, aluminum alloys such as ZL101, ZL102, ZL111 series alloys, or cast aluminum-copper alloys, grades such as ZL201, ZL202, ZL205 series alloys, or alloys mainly containing copper or The deformed aluminum alloy mainly containing silicon can also be aluminum alloy containing magnesium, such as ZL301, ZL302, etc., and adjust the temperature to 630°C-680°C, and the temperature can be 635°C, 642°C, 650°C, 660°C, 665°C , 670°C, 675°C, adding titanium hydride equivalent to 0.5%-5% of the weight of the aluminum alloy, the amount of titanium hydride can be selected as 0.8%, 1.2%, 1.5%, 2.0%, 2.8%, 3.5%, 4.2% %, 4.7%, stirring at a speed of 500-800rpm for 60-500 seconds to disperse titanium hydride, for example, 500rpm, 600rpm, 700rpm, 750rpm can be selected, and the stirring time can be selected...

Embodiment 2

[0025] A method for preparing a foamed aluminum alloy shaped part with a uniform pore structure, comprising the following steps:

[0026] Step 1: Heat the aluminum alloy until it melts. Among them, aluminum alloys such as ZL101, ZL102, ZL111 series alloys, or cast aluminum-copper alloys, grades such as ZL201, ZL202, ZL205 series alloys, or alloys mainly containing copper or The deformed aluminum alloy mainly containing silicon can also be aluminum alloy containing magnesium, such as ZL301, ZL302, etc., and adjust the temperature to 630°C-680°C, and the temperature can be 635°C, 642°C, 650°C, 660°C, 665°C , 670°C, 675°C, adding titanium hydride equivalent to 0.5%-5% of the weight of the aluminum alloy, the amount of titanium hydride can be selected as 0.8%, 1.2%, 1.5%, 2.0%, 2.8%, 3.5%, 4.2% %, 4.7%, stirring at a speed of 500-800rpm for 60-500 seconds to disperse titanium hydride, for example, 500rpm, 600rpm, 700rpm, 750rpm can be selected, and the stirring time can be selecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com