Methods of Improving the Operational Safety of Hydrocracking Units

A hydrocracking and safety technology, applied in chemical instruments and methods, hydrotreating processes, molecular sieve catalysts, etc., can solve the problems of damaged hydrocracking catalyst activity, mismatched reaction temperature, etc., and achieve good passivation effect. , The effect of suitable process conditions, reducing operating fluctuations and operating risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

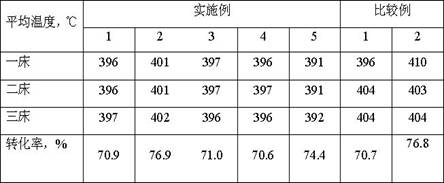

Embodiment 1

[0053] When the reaction temperature of the first bed of hydrocracking catalyst is 396°C, and the difference between the outlet temperature and the inlet temperature T1 of the first catalyst bed is 2°C, the nitrogen weight content of the catalyst in the first catalyst bed is 0.18%, Cool down to 325°C and feed refined oil with a nitrogen content of 495ppm. After the nitrogen content of the liquid phase effluent from the cracking section is constant at 50ppm, feed hydrogenated refined oil with a nitrogen content of ~40ppm, and then first raise the reaction temperature to 385°C , adjust the temperature, control the conversion rate to be constant at 35%, and stabilize for 48 hours; finally adjust the process conditions to enter normal production, and the controlled conversion depth is the same as that of Comparative Example 1.

Embodiment 2

[0055] When the reaction temperature of the first bed of hydrocracking catalyst is 397°C, and the difference between the outlet temperature and the inlet temperature T1 of the first catalyst bed is 3°C, the nitrogen content of the catalyst in the first catalyst bed is 0.16%. Feed refined oil with a nitrogen content of 320ppm to 332°C, and after the nitrogen content of the liquid phase effluent from the cracking section is constant at 50ppm, feed hydrogenated refined oil with a nitrogen content of ~40ppm, and then first increase the reaction temperature to 385°C , adjust the temperature, control the conversion rate to be constant at 35%, and stabilize for 24 hours; finally adjust the process conditions to enter normal production, and the controlled conversion depth is the same as that of Comparative Example 2.

Embodiment 3

[0057] When the reaction temperature of the first bed of hydrocracking catalyst is 397°C, and the difference between the outlet temperature and the inlet temperature T1 of the first catalyst bed is 1°C, the nitrogen content of the catalyst in the first catalyst bed is 0.28%, and the temperature is lowered Feed refined oil with a nitrogen content of 421ppm to 328°C. After the nitrogen content of the liquid phase effluent from the cracking section is constant at 80ppm, feed hydrogenated refined oil with a nitrogen content of ~40ppm, and then first increase the reaction temperature to 385°C. Adjust the temperature, control the conversion rate to be constant at 38%, and stabilize for 48 hours; finally adjust the process conditions to enter normal production, and the controlled conversion depth is the same as that of Comparative Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com