Comprehensive Utilization Method of Silicon Carbide Crystal Growth Leftovers

A silicon carbide and crystal growth technology, which is applied in the field of comprehensive utilization of silicon carbide crystal growth leftovers, can solve the problems that restrict the wide application of SiC crystals, induce inclusions, micropipe stress, and cannot reuse silicon carbide crystal growth, etc., to achieve The effect of material saving, suitable process conditions and material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1, comprehensive utilization method of silicon carbide crystal growth leftovers

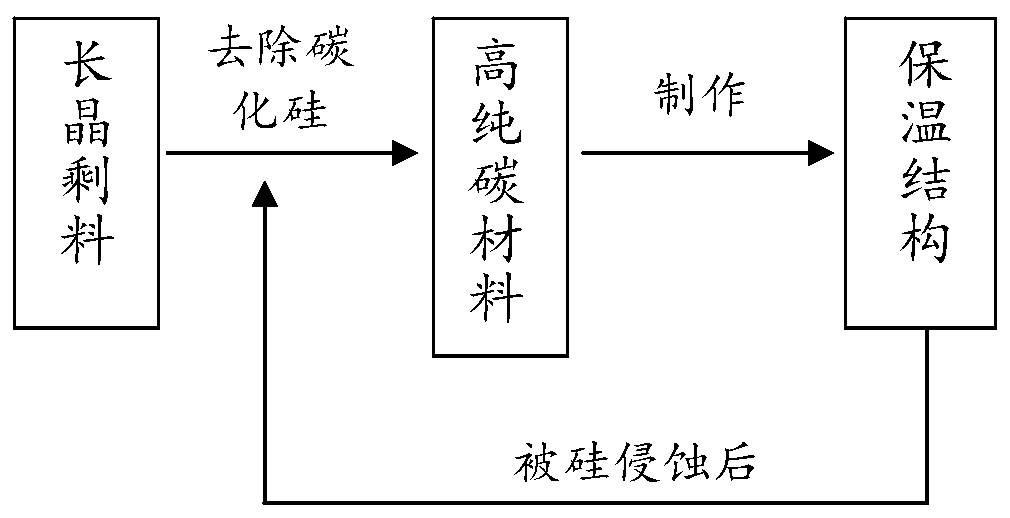

[0060] Such as figure 1 As shown, the specific process of the comprehensive utilization method of silicon carbide crystal growth leftovers is as follows:

[0061] 1. Remove silicon carbide from silicon carbide crystal growth leftovers to obtain high-purity carbon materials

[0062] In addition to carbon materials, the silicon carbide crystal growth residue also contains a part of silicon carbide polycrystal, which needs to be removed by high temperature heating. The specific method is as follows:

[0063] 1) Classify the silicon carbide crystal growth leftovers, separate the upper bulk silicon carbide polycrystal from the carbonized carbon particles at the bottom, remove the bulk silicon carbide polycrystal, and obtain a coarse material containing carbon particles;

[0064] 2) The obtained coarse material containing carbon particles (mainly carbon particles and containing a ce...

Embodiment 2

[0075] Embodiment 2, comprehensive utilization method of silicon carbide crystal growth leftovers

[0076] Carry out according to the method for embodiment 1, difference is that step one:

[0077] In step 2), in the crucible, the ratio of the crude material containing carbon particles to the volume of the crucible is 0.2:1; the distance between the coarse material containing carbon particles and the top of the crucible is 20 cm; the The mass ratio of silicon carbide to carbon in the coarse material containing carbon particles is 0.05:1;

[0078] In steps 4) and 5), after the pressure in the crucible growth chamber is 5 mbar and the temperature is 2000° C., stabilize at this low pressure and temperature for 5 hours;

[0079] Results: The purity of the high-purity carbon material was 99%, and the recovery rate was 94%.

Embodiment 3

[0080] Embodiment 3, comprehensive utilization method of silicon carbide crystal growth leftovers

[0081] Carry out according to the method for embodiment 1, difference is that step one:

[0082] In step 2), in the crucible, the ratio of the crude material containing carbon particles to the volume of the crucible is 0.8:1; the distance between the coarse material containing carbon particles and the top of the crucible is 150 cm; the The mass ratio of silicon carbide to carbon in the coarse material containing carbon particles is 1:1;

[0083] In steps 4) and 5), after the pressure in the crucible growth chamber is 30mbar and the temperature is 2300°C, stabilize at this low pressure and temperature for 30h;

[0084] Results: The purity of the high-purity carbon material was 93%, and the recovery rate was 92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com