Preparation method of monodisperse super paramagnetic ferroferric oxide nanoparticles and ferroferric oxide nanoparticles

A technology of ferroferric oxide and nanoparticles, which is applied in the preparation of monodisperse superparamagnetic ferroferric oxide nanoparticles, in the field of monodisperse superparamagnetic ferroferric oxide nanoparticles, which can solve the problem of high energy consumption and long reaction time Long, large particle size control and other issues, to achieve the effect of simple preparation method, simple and convenient synthesis process, and mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

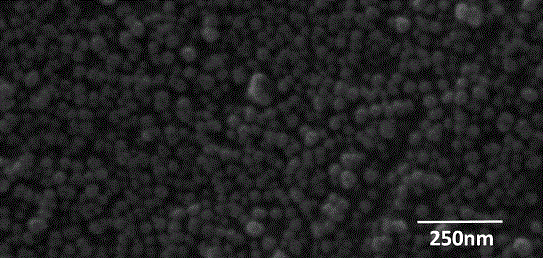

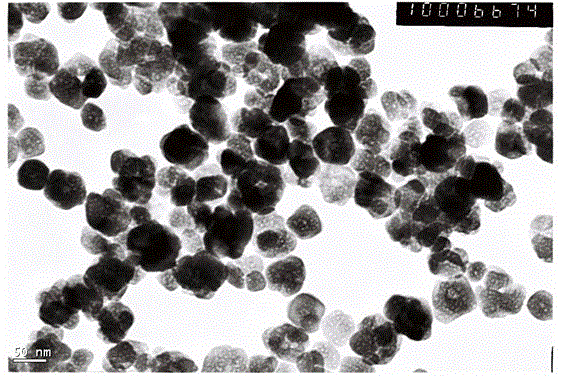

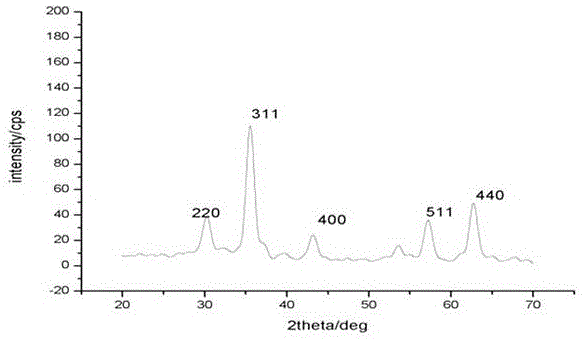

Image

Examples

Embodiment 1

[0037] Example 1 Preparation of Monodisperse Superparamagnetic Iron Tetroxide Nanoparticles

[0038] S1.Fe 3 o 4 Synthesis of Magnetic Particles

[0039] 1g FeCL 3 ·6H 2 O was dissolved in 20 mL of ethylene glycol organic solvent and stirred to form a clear solution. Then add 3g of sodium acetate and 10mL of ethylenediamine, stir vigorously for 30min and ultrasonically (ultrasonic cleaner) for 10min to make it into an orange-yellow clear solution. The reaction was carried out at 200° C. for 8 hours in a drying oven.

[0040] After the reaction, cool to room temperature. After several times of deionized water washing, the nano Fe can be obtained 3 o 4 magnetic particles.

[0041] S2. Surface modification of magnetic particles

[0042] Dissolve 0.3g of polyacrylic acid in 10mL of dimethylformamide, Fe 3 o 4 After ultrasonic treatment for 30 minutes, the magnetic particles were added to 20 mL of dimethylformamide, mixed and stirred, then transferred to a container lined...

Embodiment 2

[0043] Example 2 Preparation of Monodisperse Superparamagnetic Iron Tetroxide Nanoparticles

[0044] S1.Fe 3 o 4 Synthesis of Magnetic Particles

[0045] 1g FeCL 3 ·6H 2 O was dissolved in 20 mL of ethylene glycol organic solvent and stirred to form a clear solution. Then add 3g of sodium acetate and 10mL of ethylenediamine, stir vigorously for 30min and sonicate for 10min to make it into an orange-yellow clear solution. The reaction was carried out for 10 hours.

[0046] After the reaction, cool to room temperature. After several times of deionized water washing, the nano Fe can be obtained 3 o 4 magnetic

[0047] sex particles.

[0048] S2. Surface modification of magnetic particles

[0049] Dissolve 0.3g of polyacrylic acid in 10mL of dimethylformamide, Fe 3 o 4 After ultrasonic treatment for 30 minutes, the magnetic particles were added to 20 mL of dimethylformamide, mixed and stirred, then transferred to a container lined with a hydrothermal reaction kettle, ...

Embodiment 3

[0050] Example 3 Preparation of Monodisperse Superparamagnetic Iron Tetroxide Nanoparticles

[0051] S1.Fe 3 o 4 Synthesis of Magnetic Particles

[0052] 1g FeCL 3 ·6H 2 O was dissolved in 20 mL of ethylene glycol organic solvent and stirred to form a clear solution. Then add 3g of sodium acetate and 10mL of ethylenediamine, stir vigorously for 30min and sonicate for 10min to make it into an orange-yellow clear solution. The reaction was carried out for 12 hours. After the reaction, cool to room temperature. After several times of deionized water washing, the nano Fe can be obtained 3 o 4 magnetic particles.

[0053] S2. Surface modification of magnetic particles

[0054] Dissolve 0.3g of polyacrylic acid in 10mL of dimethylformamide, Fe 3 o 4 The magnetic particles were ultrasonically treated for 30 minutes and added to 20 mL of dimethylformamide. The two were mixed and stirred, then transferred to a container lined with a hydrothermal reaction kettle, sealed and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com