Hydrocracking start-up method

A technology of hydrocracking and nitrides, which is applied in the fields of hydroprocessing technology, chemical instruments and methods, and the petroleum industry, and can solve problems such as the influence of catalyst activity, poor passivation effect of inert gas, and reduced stability and safety of the start-up process. Achieve the effect of accelerating the initial activity stabilization process, improving catalyst activity, and good passivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

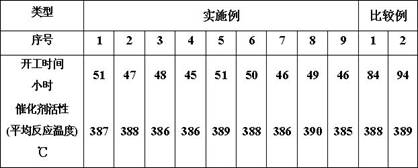

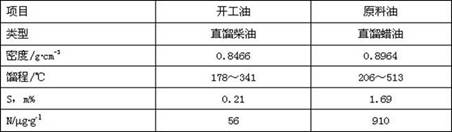

Embodiment 1

[0037] Firstly, low nitrogen start-up oil, hydrogen and vulcanizing agent are introduced into the hydrocracking unit, and then the hydrocracking catalyst is subjected to constant temperature vulcanization under the condition of 220°C. 4% of the theoretical dosage, after the hydrogen sulfide content in the circulating hydrogen reaches 4000ppm, reduce the adding rate of the sulfurizing agent to 1% of the theoretical dosage of the sulfurizing agent per hour and increase the bed temperature of the hydrocracking catalyst to 320°C, the time used is 15h, When the bed temperature of the hydrocracking catalyst reaches 320°C, increase the adding rate of the vulcanizing agent to 3% of the theoretical amount of the vulcanizing agent per hour, continue constant temperature vulcanization for 3 hours, then raise the temperature to 385°C and feed the raw material oil for reaction, wherein the The hydrocracking catalyst contains 2% nitrogen element, 6% nickel oxide, 23% tungsten oxide and 10% Y...

Embodiment 2

[0039] Firstly, low nitrogen start-up oil, hydrogen and vulcanizing agent are introduced into the hydrocracking unit, and then the hydrocracking catalyst is vulcanized at a constant temperature at 230°C. 5% of the theoretical dosage, after the hydrogen sulfide content in the circulating hydrogen reaches 5000ppm, reduce the adding rate of the sulfurizing agent to 1.5% of the theoretical dosage of the sulfurizing agent per hour and increase the bed temperature of the hydrocracking catalyst to 325°C, and the time used is 13h. When the bed temperature of the hydrocracking catalyst reaches 325°C, increase the addition rate of the vulcanizing agent to 4% of the theoretical amount of vulcanizing agent per hour, continue the constant temperature vulcanization for 2 hours, then raise the temperature to 385°C and feed the raw material oil for reaction, wherein the The hydrocracking catalyst contains 2% nitrogen element, 6% nickel oxide, 23% tungsten oxide and 10% Y-type molecular sieve b...

Embodiment 3

[0041] Firstly, low-nitrogen start-up oil, hydrogen and vulcanizing agent are introduced into the hydrocracking unit, and then the hydrocracking catalyst is subjected to constant temperature vulcanization under the condition of 240°C. 3% of the theoretical amount, after the hydrogen sulfide content in the circulating hydrogen reaches 3000ppm, reduce the addition rate of the sulfide agent to 0.8% of the theoretical amount of the sulfide agent per hour and increase the bed temperature of the hydrocracking catalyst to 330°C, and the time used is 10h. When the bed temperature of the hydrocracking catalyst reaches 330°C, increase the addition rate of the vulcanizing agent to 3% of the theoretical amount of vulcanizing agent per hour, continue constant temperature vulcanization for 4 hours, then raise the temperature to 380°C and feed the raw material oil for reaction, wherein the The hydrocracking catalyst contains 1.8% nitrogen element, 6% nickel oxide, 23% tungsten oxide, and 10% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com