Rubber composition for all-steel tread, and preparation method thereof

A technology of rubber composition and steel tire, which is applied in the field of tire rubber materials, can solve the problem that the wear resistance and tear resistance of rubber materials are difficult to achieve a good balance, which is unfavorable for tire usability and tear resistance of rubber materials. To improve low rolling resistance, improve processability, and take into account tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

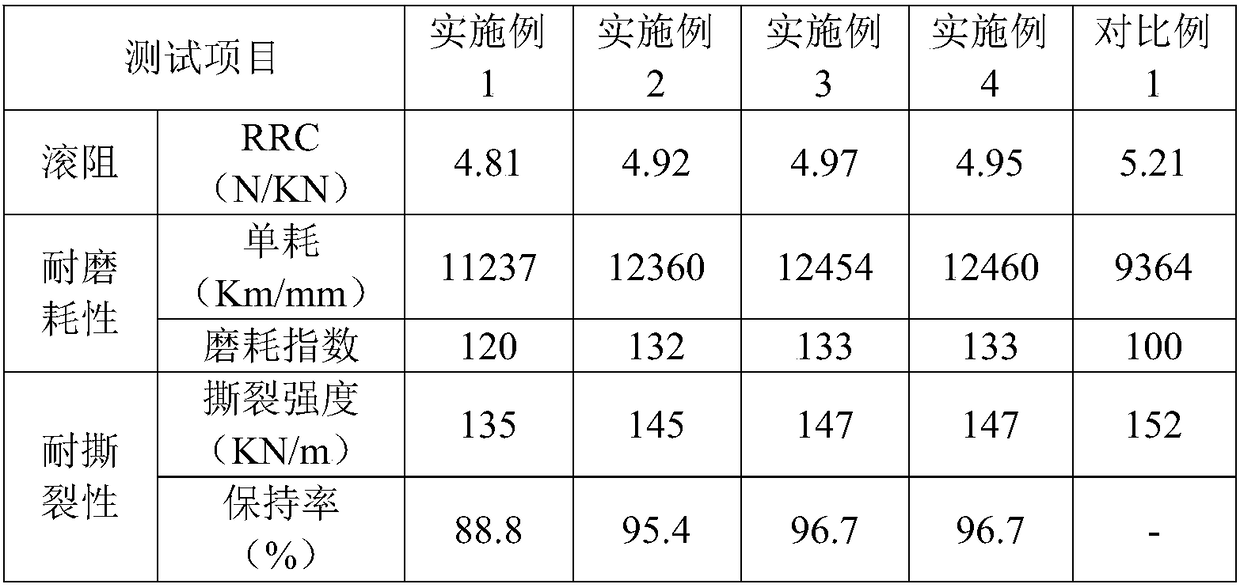

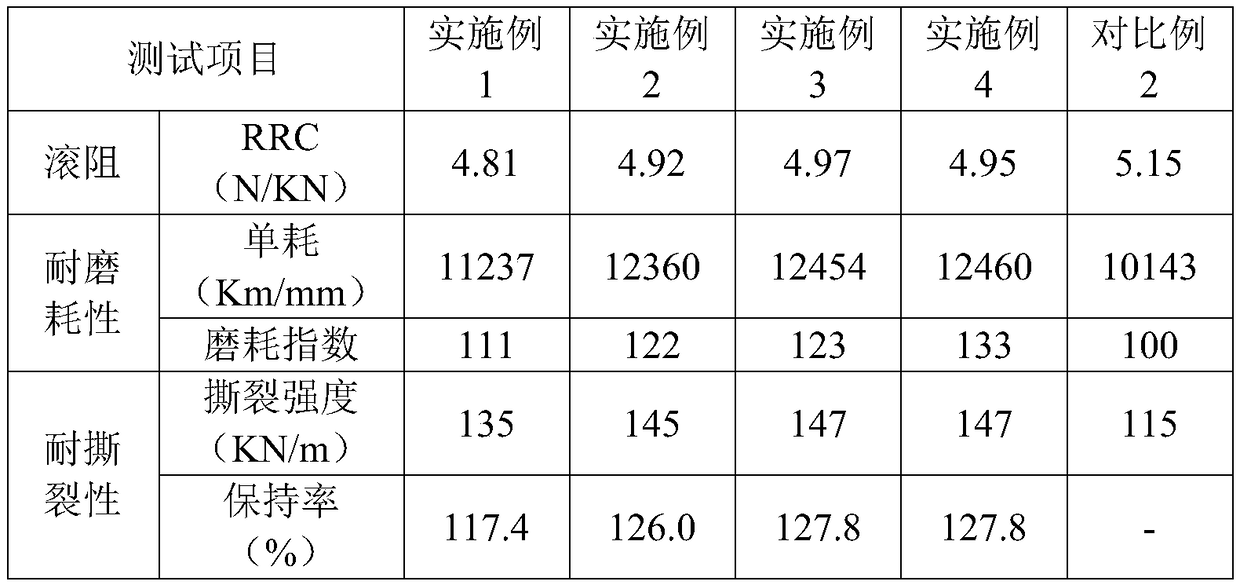

Examples

Embodiment 1

[0037] 50 parts of natural rubber, 50 parts of neodymium branched butadiene rubber, 55 parts of N134 carbon black, 1.5 parts of metal saponified product, 1 part of microcrystalline wax, 2,2,4-trimethyl-1,2-dihydroquinoline 1 part of morphine polymer, 2 parts of N-phenyl-N'-(1,3-dimethylbutyl)-p-phenylenediamine, 0.5 part of N, N'-xylyl-p-phenylenediamine, 1 part of ordinary sulfur 2 parts, 2 parts of N-tert-butyl-2-benzothiazole hypoxanthamide, 2 parts of zinc oxide, 4 parts of stearic acid, 0.2 parts of N-cyclohexylthiophthalimide.

[0038] The preparation method that the rubber composition described in this embodiment adopts, comprises the following steps:

[0039] S1, put the natural rubber, neodymium branched butadiene rubber, dispersant, anti-aging agent, and active agent respectively according to the ratio of this embodiment into the internal mixer, the rotating speed of the internal mixer is 50rpm, the pressure is 110Bar, pressurize Lift the mound for 20S, then add N13...

Embodiment 2

[0045] 70 parts of natural rubber, 30 parts of neodymium-based branched butadiene rubber, 47 parts of N134 carbon black, 2 parts of metal saponification, 2 parts of microcrystalline wax, 2,2,4-trimethyl-1,2-dihydroquinone 3 parts of morphine polymer, 1.5 parts of ordinary sulfur, 1.5 parts of N-tert-butyl-2-benzothiazole hyposinamide, 2 parts of zinc oxide, 2 parts of stearic acid, N-cyclohexylthiophthaloyl 0.5 part of imine.

[0046] The preparation method that the rubber composition described in this embodiment adopts, comprises the following steps:

[0047]S1, put the natural rubber, neodymium branched butadiene rubber, dispersant, anti-aging agent, and active agent weighed respectively according to the proportioning described in this embodiment into the internal mixer, the rotating speed of the internal mixer is 40rpm, and the pressure is 100Bar , pressurize for 40S to lift the mound, then add N134 carbon black into the internal mixer and pressurize for 60S to lift the mo...

Embodiment 3

[0053] 90 parts of natural rubber, 10 parts of neodymium branched butadiene rubber, 40 parts of N134 carbon black, 1 part of metal saponified product, 1 part of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 1 part of N, N'-xylyl-p-phenylenediamine, 2 parts of insoluble sulfur, 1.5 parts of N-tert-butyl-2-benzothiazole hypoxanthamide, 3 parts of zinc oxide, 1.5 parts of stearic acid, N- 0.35 parts of cyclohexylthiophthalimide.

[0054] The preparation method that the rubber composition described in this embodiment adopts, comprises the following steps:

[0055] S1, put the natural rubber, neodymium branched butadiene rubber, dispersant, anti-aging agent, and active agent into the internal mixer according to the proportioning ratio described in this embodiment, the rotating speed of the internal mixer is 45rpm, and the pressure is 90Bar , pressurize for 30S to lift the mound, then add N134 carbon black into the internal mixer and pressurize for 65S to lift the mound, then mix a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com