Preparation method of light guide plate, light guide plate, backlight module and display device

A technology of light guide plate and light emitting surface, which is used in printing devices, light guides, optics, etc., can solve the problems of long contact time between the light guide plate and high-temperature molds, poor yellowing cannot be fundamentally solved, and the chromaticity of the light source has a great influence. Eliminate poor yellowing, improve poor yellowing, and reduce the effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

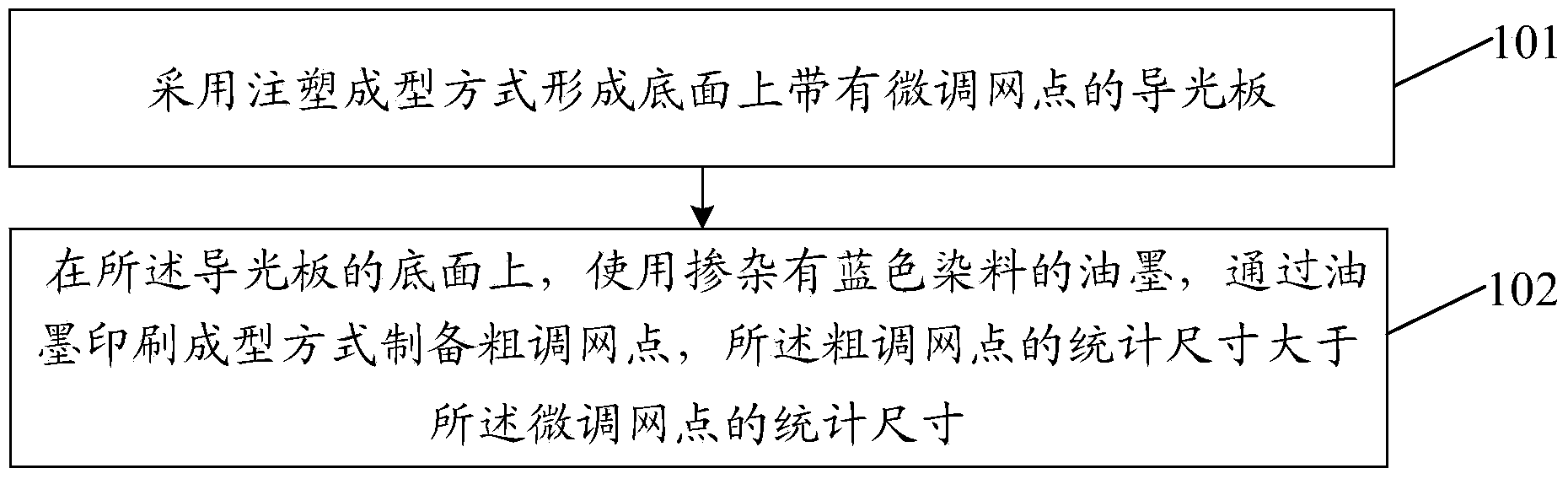

[0027] Embodiments of the present invention provide a method for preparing a light guide plate, such as figure 1 As shown, the method includes:

[0028] 101. A light guide plate with fine-tuning dots on the bottom surface is formed by injection molding, and the bottom surface is opposite to the light-emitting surface of the light guide plate;

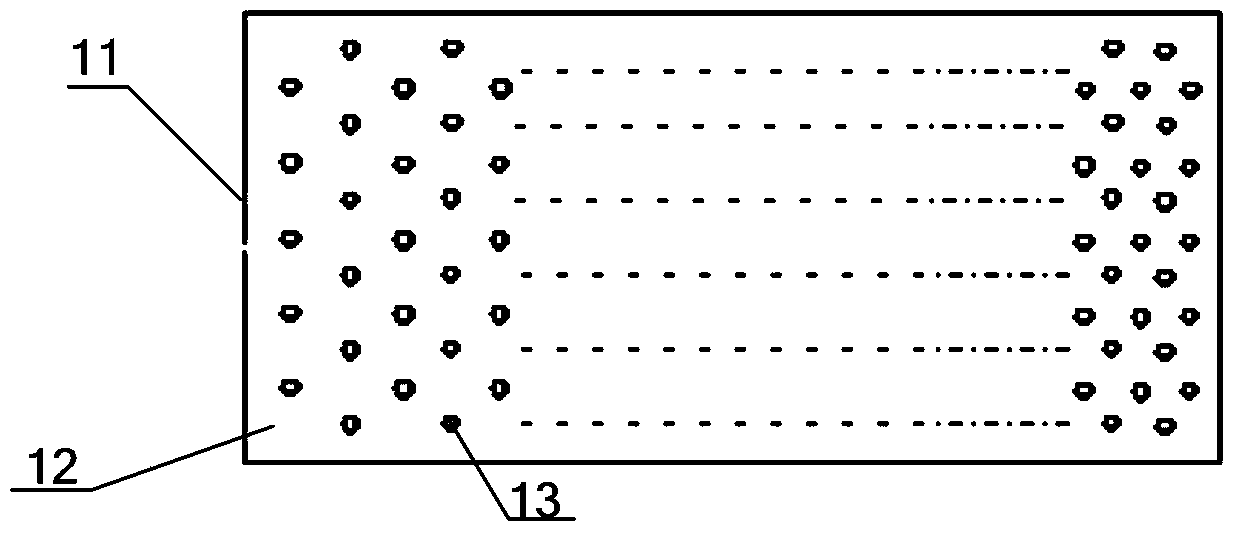

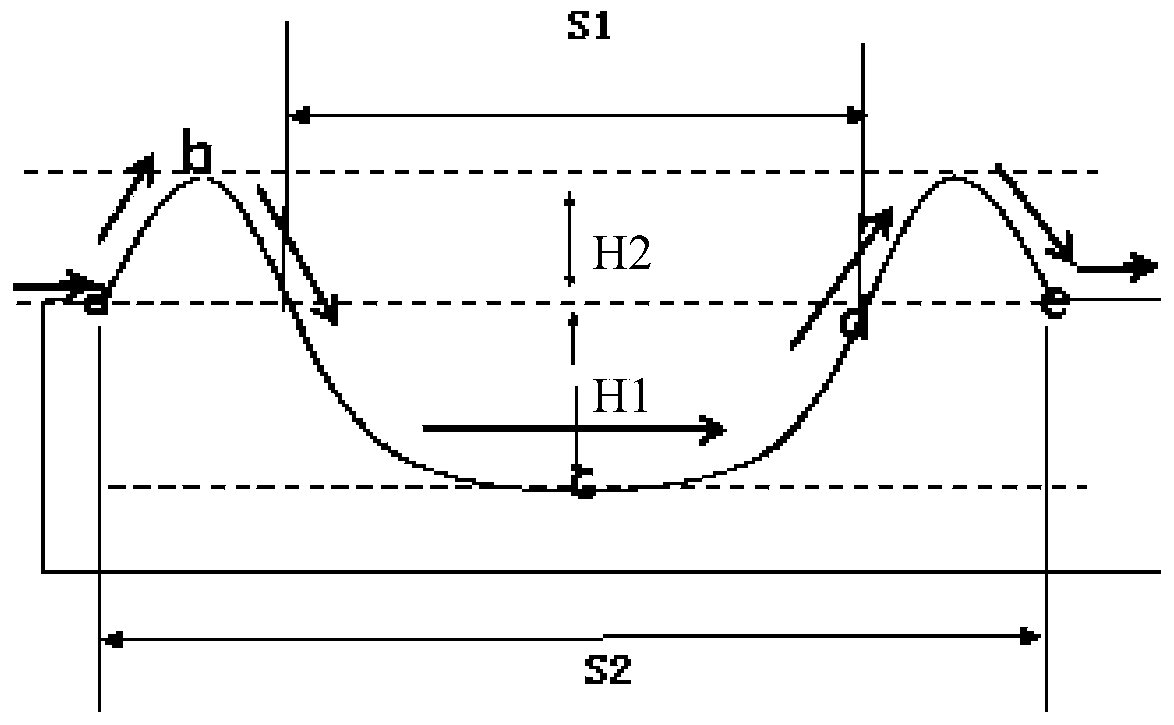

[0029] The dots on the light guide plate are the main factors affecting the light quality, so the dot design is a key point in the design of the backlight module. Dot design means that the designer optimizes the shape, size, distribution density, and distribution rules of the dots on the bottom surface of the light guide plate by using the corresponding dot design software and combining the experience accumulated by the designer, so that the light output of the light guide plate meets the product requirements. The dot design is not the focus of the implementation of the present invention, and is not directly related to the implementati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com